Extraction method of high-activity biomass lignin

An extraction method and technology for lignin, applied in the field of lignin, can solve problems such as low extraction cost, and achieve the effects of wide distribution, complete structure and large amount of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

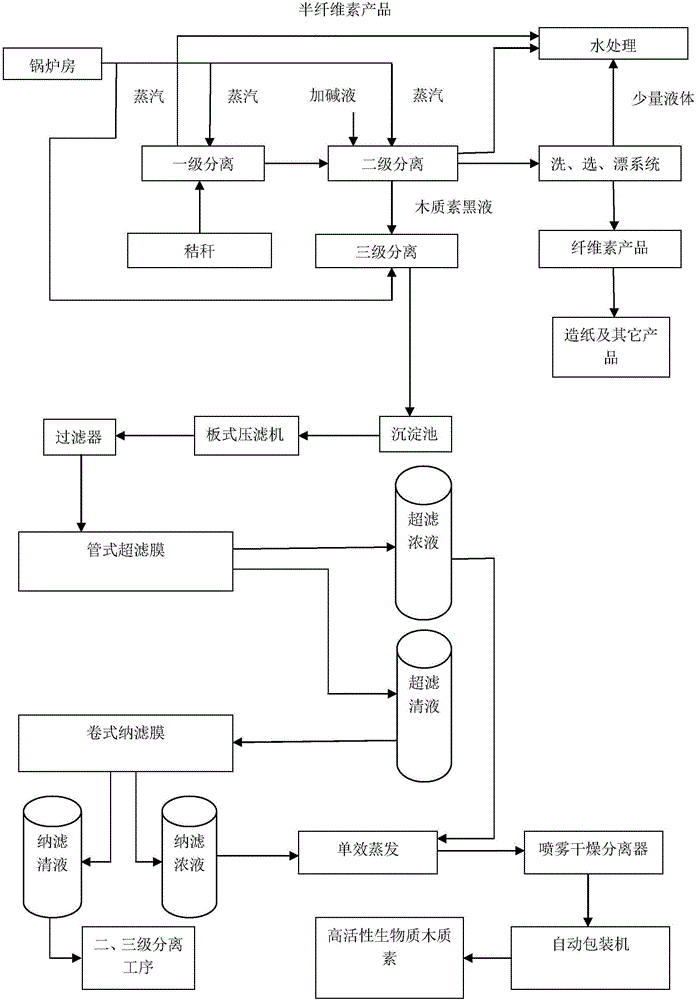

[0039] The extraction method of high activity biomass lignin comprises the following steps:

[0040] (1) primary separation

[0041] The wheat straw is cut and dedusted by a pulverizer. The length of the straw is 3-5cm, and it is sent to the steam explosion separator through a conveyor belt. It is continuously cooked in an environment of 3.0-4.0MPa for 3-5min, and then cleaned and separated from solid and liquid. The low-concentration sugar liquid and the relatively pure wheat solids from which most of the hemicellulose liquid and various plant polysaccharides have been removed are respectively obtained; among them, the low-concentration sugar liquid is sent to the anaerobic Biogas products are produced in the fermentation system, and the generated sludge is used to produce organic fertilizer products;

[0042] (2) Secondary separation

[0043]Cook and separate the wheat solids, add lye that accounts for 6wt% of the wheat solids at the same time, cook continuously at 110°C f...

Embodiment 2

[0054] The extraction method of high activity biomass lignin comprises the following steps:

[0055] (1) Add the lignin black liquor produced in the pulping process of the paper mill to the sedimentation tank through the pipeline, and add 50ppm of Ca(OH) 2 Carry out flocculation and sedimentation to obtain the lignin supernatant, and then press the lignin supernatant with a plate and frame filter press to remove lignin black liquor impurities and cellulose, and then filter through a filter with a filtration accuracy of 20 μm , to obtain lignin serum;

[0056] (2) Membrane concentration

[0057] The lignin clear liquid is sent to the tubular ultrafiltration membrane, and the pressure of the ultrafiltration membrane stack is controlled by DCS to be 5.0-8.0MPa, the temperature is 40°C, and the flux is 70m 3 , to obtain ultrafiltration concentrated liquid and ultrafiltrated liquid, the ultrafiltrated liquid is filtered and separated through the roll-type nanofiltration membrane,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com