Method of improving center segregation quality of hypo-peritectic steel casting slabs

A peritectic and steel casting technology, which is applied in the field of slab continuous steel casting, can solve problems such as large process fluctuations, and achieve the effects of improving the segregation quality of the casting slab center, fast flow speed, and accelerating superheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for improving the center segregation quality of sub-peritectic steel slabs is applied to produce sub-peritectic steel slabs with a thickness of 230 mm, a carbon content of 0.12%, and a casting speed of 1.2 m / min. The specific process is as follows:

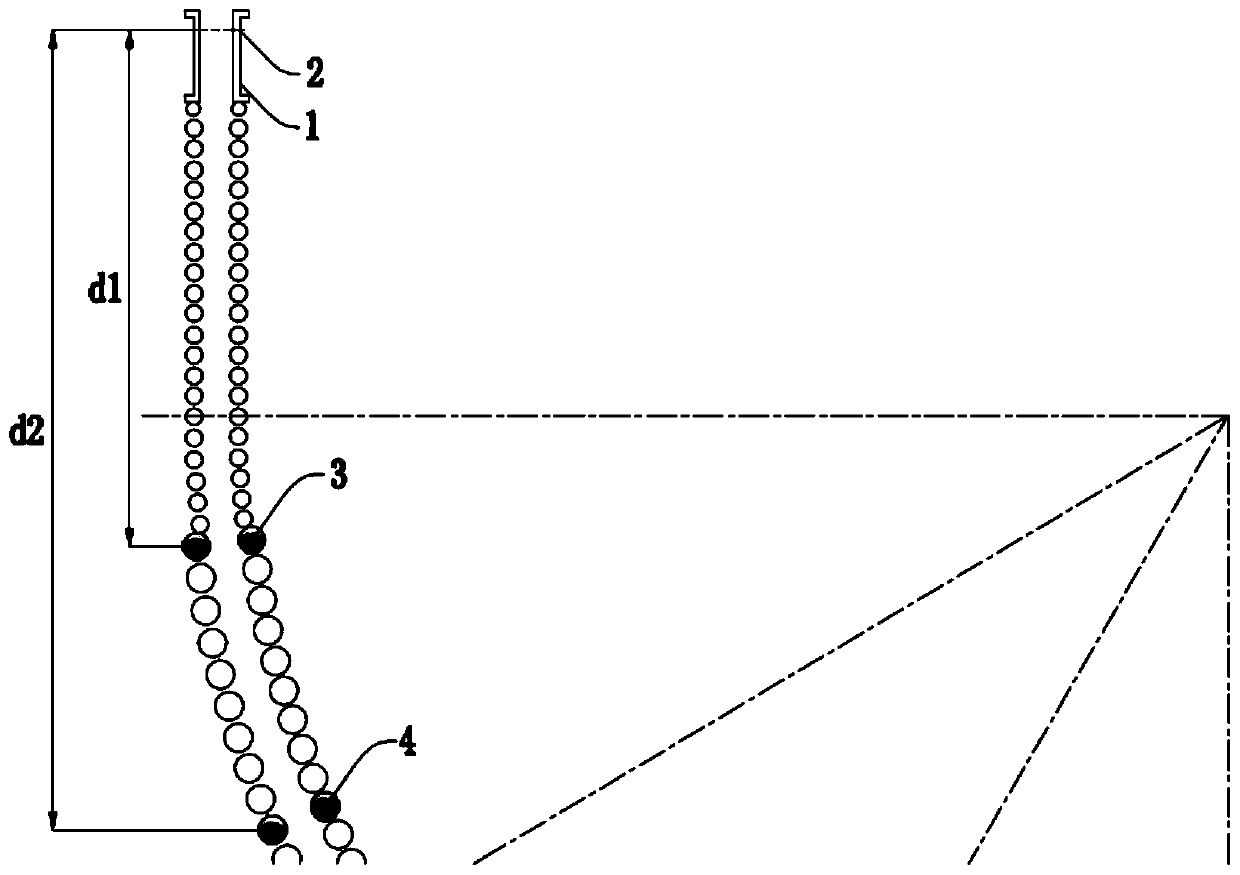

[0041] Ⅰ, such as figure 1 As shown, two pairs of electromagnetic stirring rollers are installed in the second cold zone behind the mold 1 of the slab continuous casting machine:

[0042] A. The first pair of electromagnetic stirring rollers 3 is installed at a vertical distance d1 of 4.5m from the meniscus 2 of the mold, the current is 250A, and the frequency is 3Hz; the second pair of electromagnetic stirring rollers 4 is installed at the distance from the meniscus 2 of the mold The vertical distance d2 is 7.2m, the current is 350A, and the frequency is 4Hz;

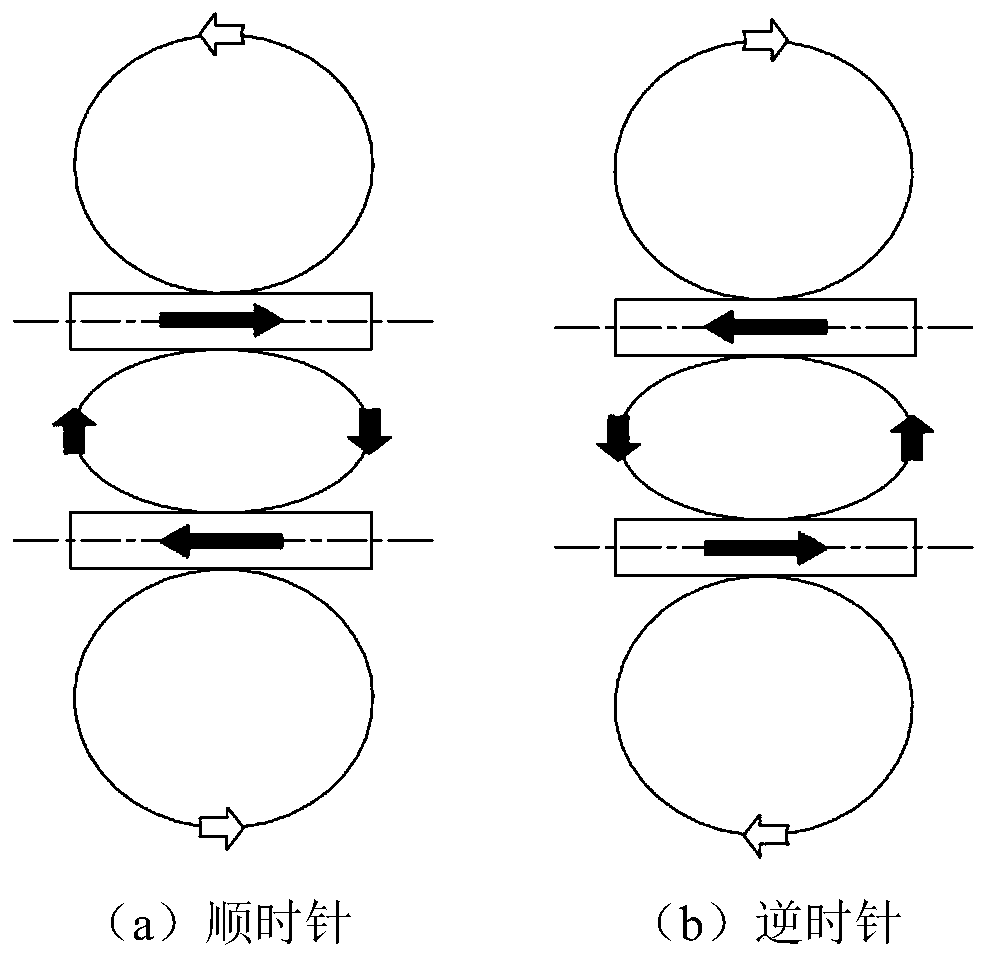

[0043] B. The "three-ring" arrangement is adopted between the two pairs of electromagnetic stirring rollers to make the molten steel flow pattern like figure 2 ...

Embodiment 2

[0048] In this embodiment, a method for improving the quality of center segregation of sub-peritectic steel slab is different and improved from embodiment 1 in that it is applied to a production thickness of 250mm, a carbon content of 0.17%, and a casting speed of 0.8m. / min sub-peritectic steel casting billet, the specific process is as follows:

[0049] Ⅰ, such as figure 1 As shown, two pairs of electromagnetic stirring rollers are installed in the second cold zone behind the mold 1 of the slab continuous casting machine:

[0050] A. The first pair of electromagnetic stirring rollers 3 is installed at a vertical distance d1 of 3.5m from the meniscus 2 of the mold, the current is 200A, and the frequency is 4Hz; the second pair of electromagnetic stirring rollers 4 is installed at the distance from the meniscus of the mold 2 The vertical distance d2 is 8m, the current is 300A, and the frequency is 5Hz;

[0051] B. The "three-ring" arrangement is adopted between the two pairs of elec...

Embodiment 3

[0056] In this embodiment, a method for improving the center segregation quality of sub-peritectic steel slabs is different and improved from Embodiments 1 and 2 in that it is applied to a production thickness of 210 mm, a carbon content of 0.06%, and a casting speed of 1.6m / min sub-peritectic steel casting billet, the specific process is as follows:

[0057] Ⅰ, such as figure 1 As shown, two pairs of electromagnetic stirring rollers are installed in the second cold zone behind the mold 1 of the slab continuous casting machine:

[0058] A. The first pair of electromagnetic stirring rollers 3 is installed at a vertical distance d1 of 4m from the meniscus 2 of the mold, the current is 300A, and the frequency is 2Hz; the second pair of electromagnetic stirring rollers 4 is installed perpendicular to the meniscus 2 of the mold The distance d2 is 7m, the current is 400A, and the frequency is 3Hz;

[0059] B. The "three-ring" arrangement is adopted between the two pairs of electromagnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com