Stress sensor, preparation method and electronic skin

A stress sensor and dielectric layer technology, applied in the field of sensors, can solve the problems of inability to measure the position of the force application point, increase the difficulty of sensor production, and low detection accuracy, and achieve the effects of simple structure, convenient operation, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

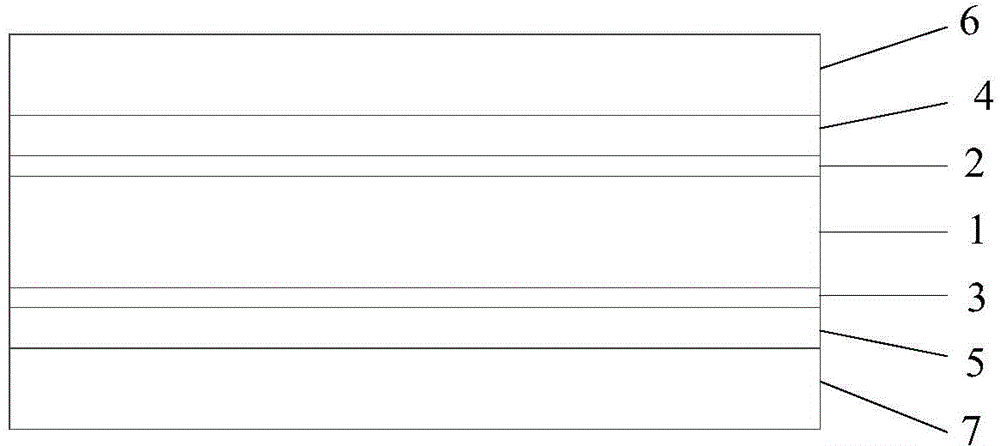

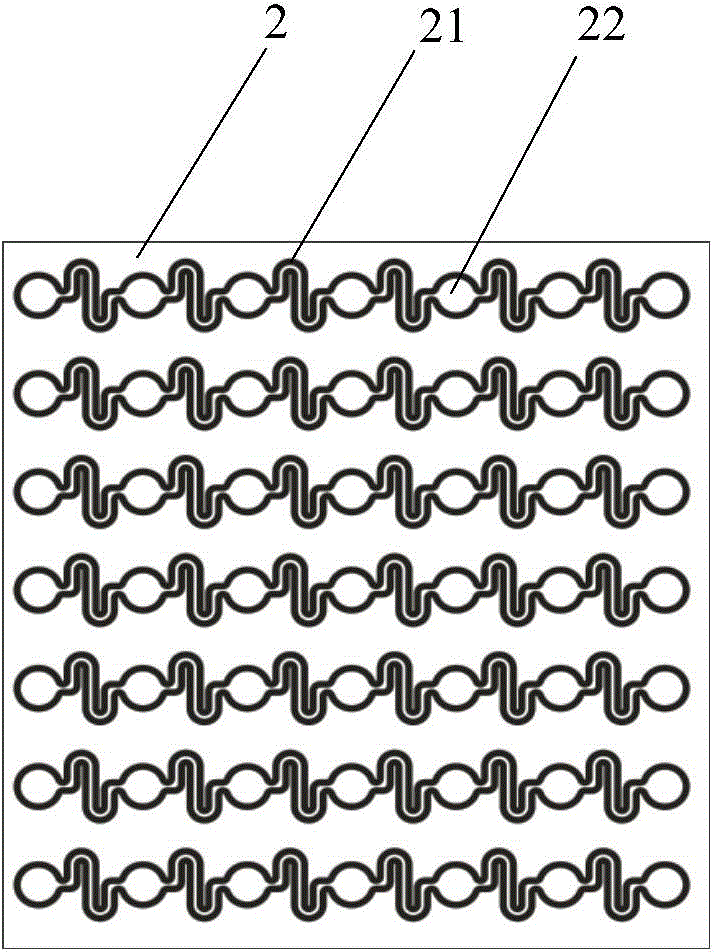

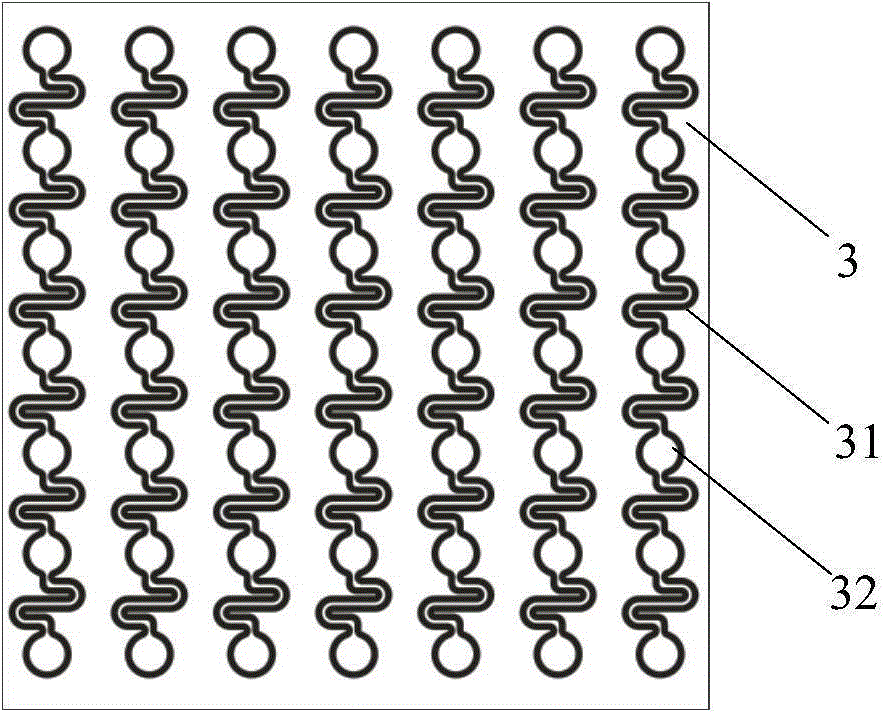

[0066] The present invention also provides a preparation method of a strain sensor, the preparation method comprising: respectively providing at least one first electrode unit and at least one second electrode unit; and coating the first electrode unit and the second electrode unit Cover a thin film to form a dielectric layer, so that the first electrode unit is arranged on the upper surface of the dielectric layer, the second electrode unit is arranged on the lower surface of the dielectric layer, and the second The electrode unit crosses the first electrode unit to form a capacitor array.

[0067] Wherein, the first electrode unit includes a curved first wire, and a first conductive node is provided on the first wire; the second electrode unit includes a curved second wire, and the second wire is provided with a A second conductive node is provided; the first conductive node and the second conductive node are respectively the upper plate or the lower plate of the correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com