Rope-shaped dyeing machine

A rope-like dyeing machine and dyeing tank technology, applied in the field of dyeing machines, can solve the problems of lower dyeing quality, high energy consumption, and complexity, and achieve the effects of improving dyeing quality, dyeing convenience, and large kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

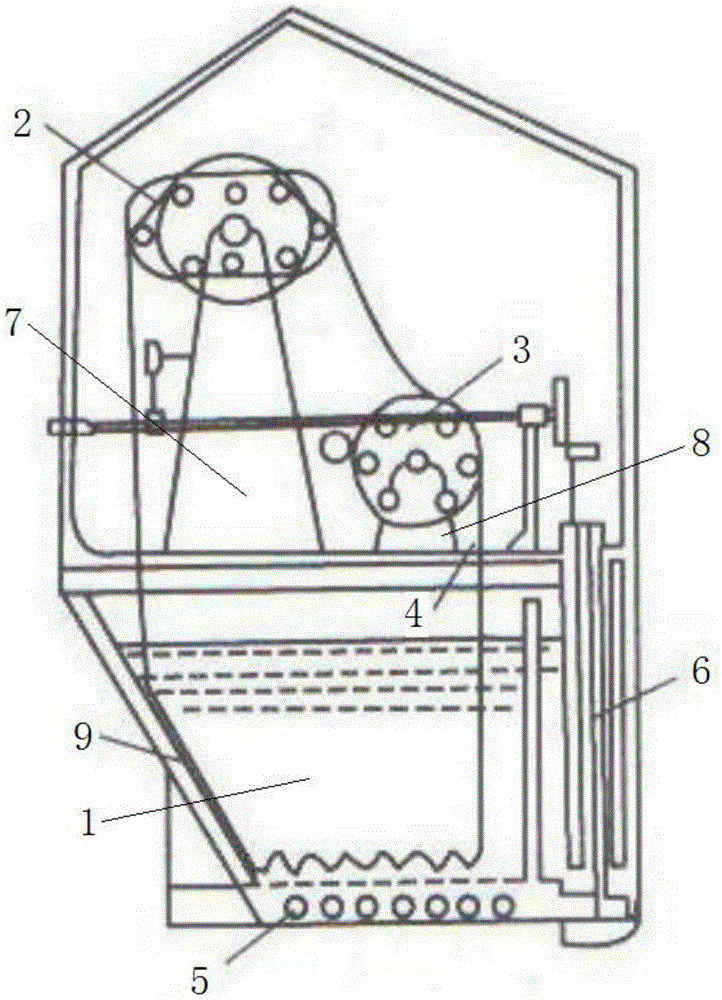

[0014] like figure 1 As shown, a rope dyeing machine includes a dyeing tank 1, an active cloth guide roller 2, a driven cloth guide roller 3, a distribution gear 4 and a liquid feeding pipe 6. The inside of the dyeing tank 1 contains dyeing liquid, and The top of the dyeing tank 1 is provided with a main support 7 and a slave support 8, the active cloth guide roller 2 is arranged on the main support 7 and can rotate around the main support 7, the active cloth guide roller 2 is connected with the motor, and the slave The movable fabric guide roller 3 is arranged on the secondary support 8 and can rotate around the secondary support 8. The height of the active fabric guide roller 2 set on the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com