Heating device and method for heating steel pipe circular seams by using heating device

A technology for heating devices and steel pipes, applied in the field of heating devices and steel pipe ring seam heating, can solve the problems of long time consumption, large labor investment, electric shock, etc., and achieve the effect of convenient use, flexible movement and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

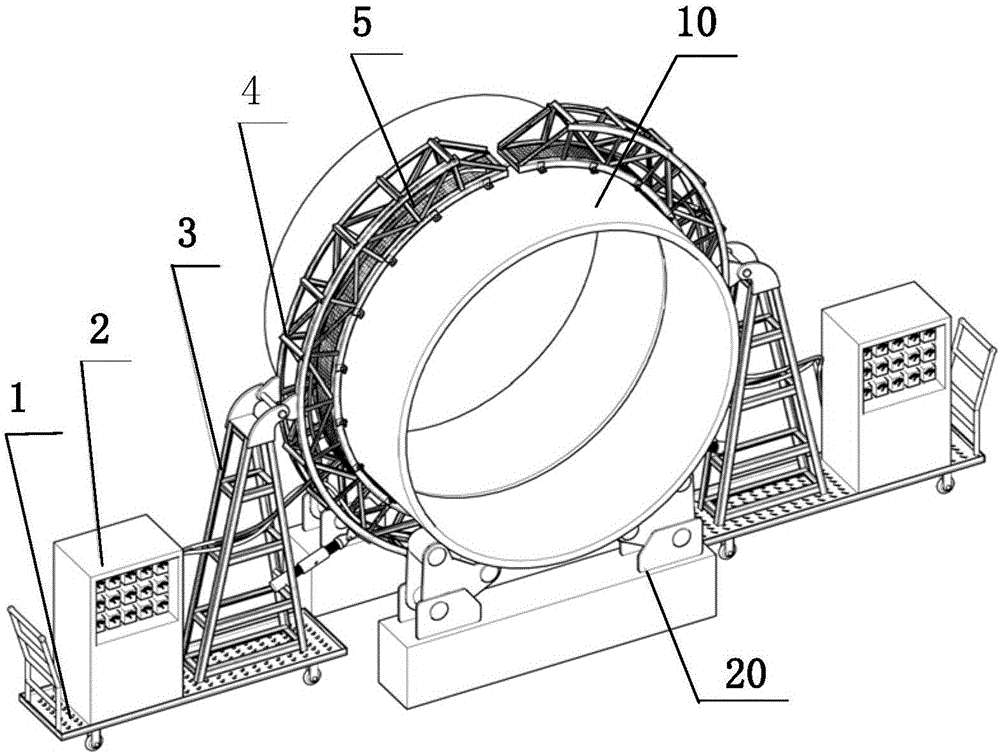

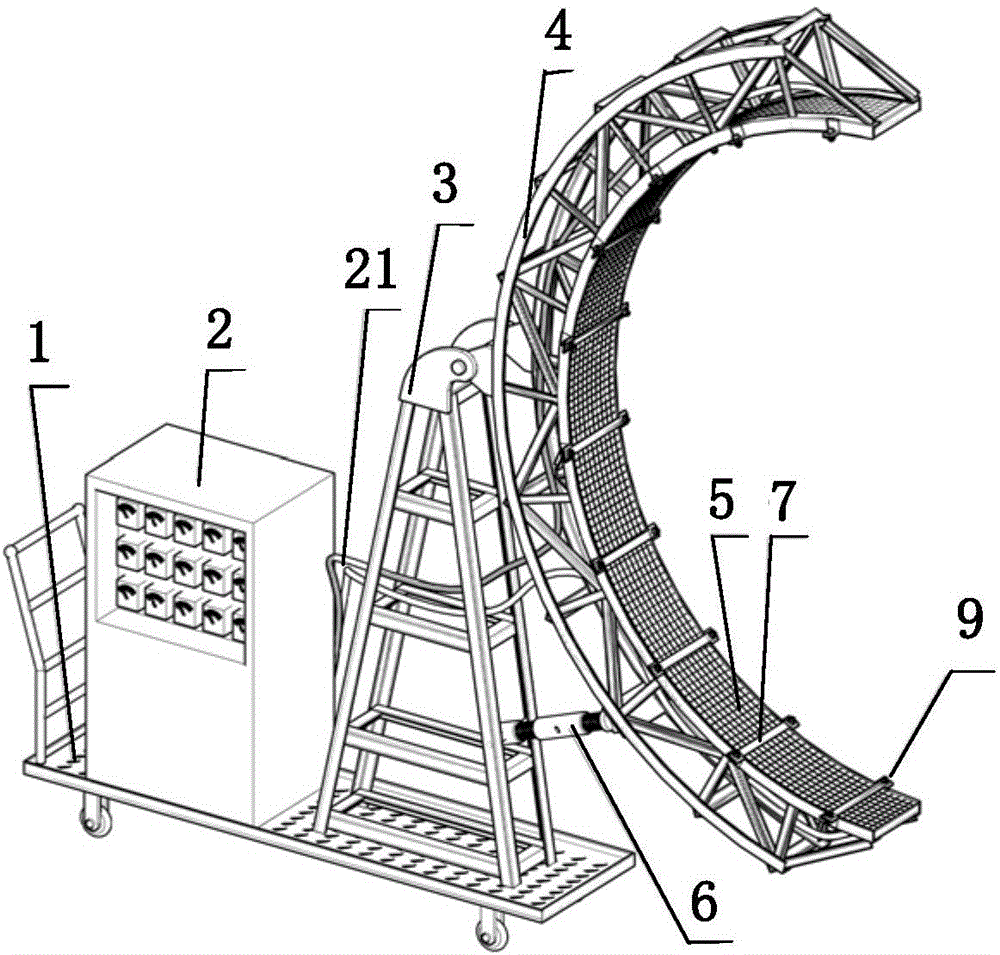

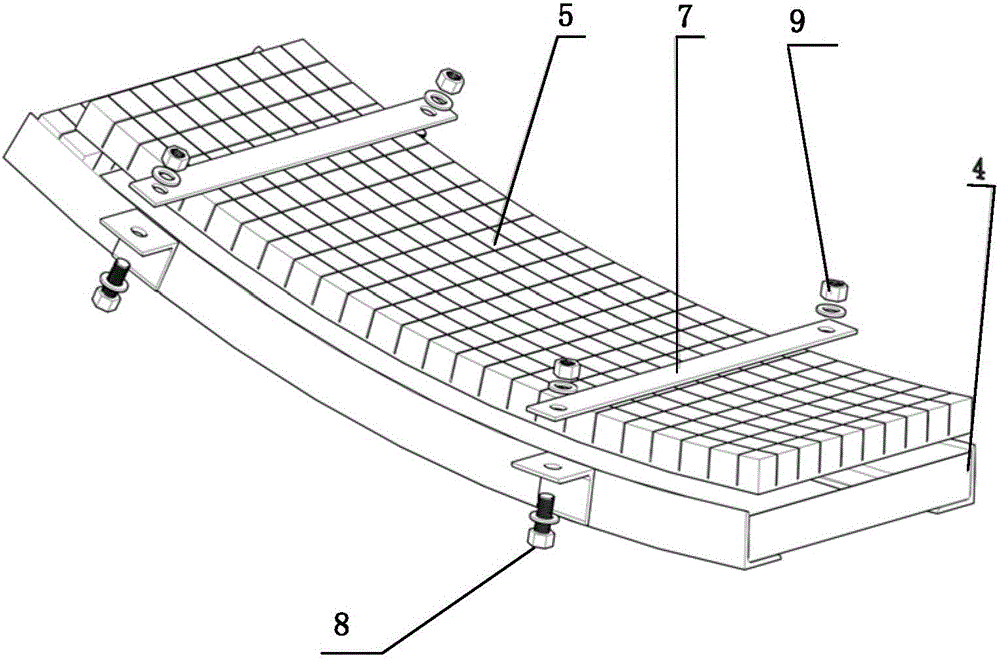

[0033] see figure 1 , The heating device provided by Embodiment 1 of the present invention is mainly used for heating the annular seam of steel pipe 10, and includes a moving device 1, a temperature control device 2, a fixed bracket 3 and a tracked heating plate bracket 4 arranged on the moving device 1. The mobile device 1 is used to carry the entire heating device, and can be moved to meet the requirements for switching between processes. Its structure may include a storage plate and wheels arranged under the storage plate for moving, such as moving mechanisms such as trolleys. The fixed bracket 3 is fixed on the mobile device 1 and connected with the crawler heating plate support 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com