System for automatically detecting periodic error of photoelectric distance measuring instrument

A photoelectric range finder and periodic error technology, which is applied to instruments, measuring devices, etc., can solve the problems of heavy workload and low work efficiency, and achieve the effects of simple processing, saving manpower, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

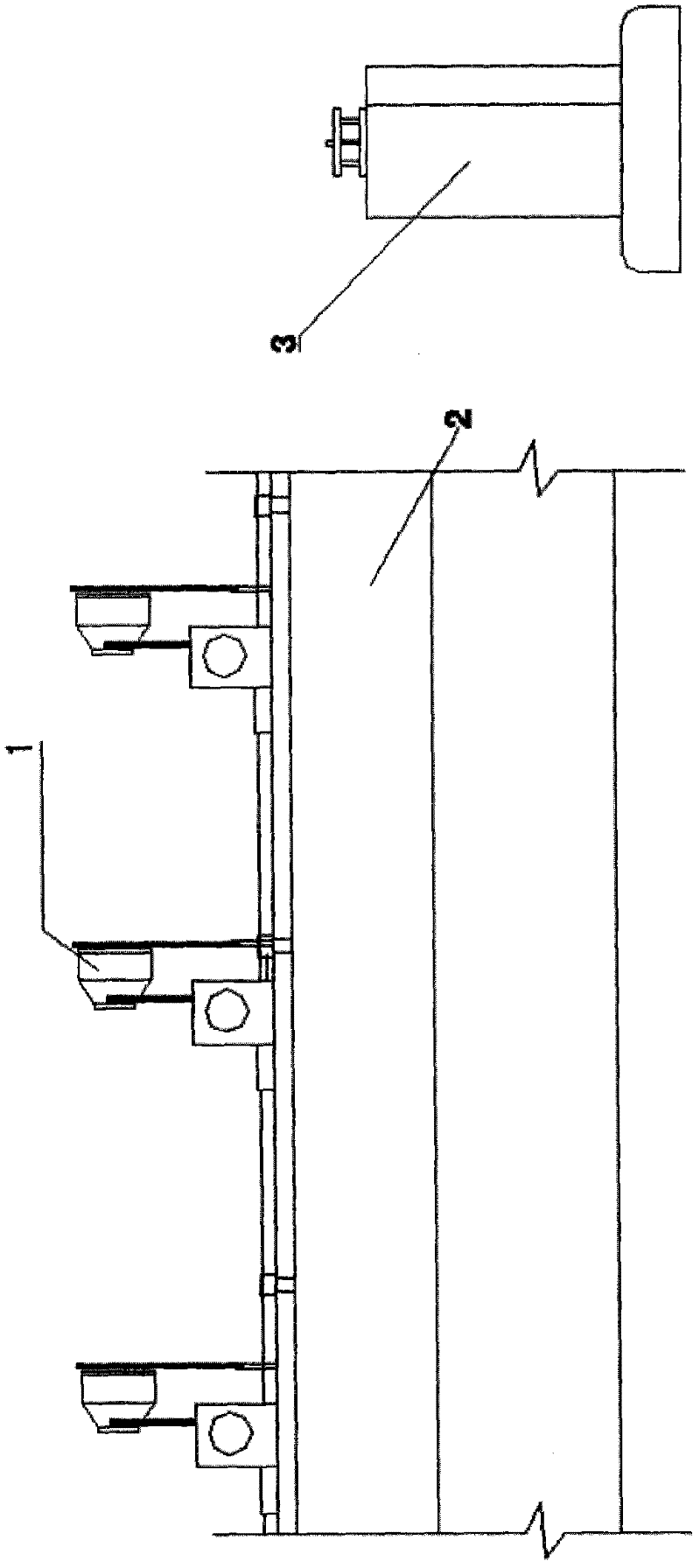

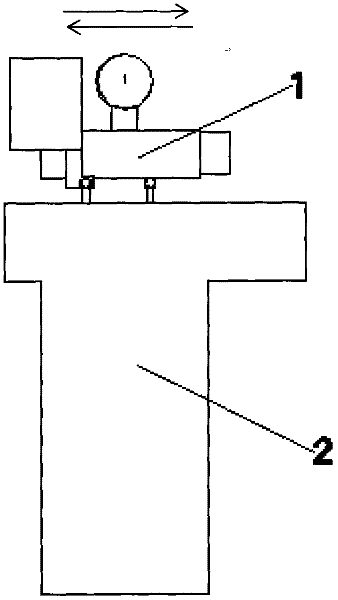

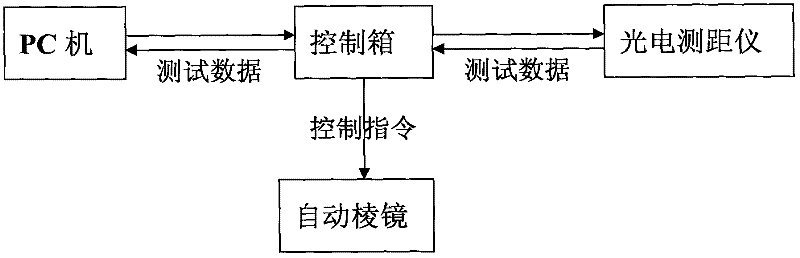

[0036] Such as figure 1 , figure 2 , image 3 , Figure 10 , Figure 11 The automatic verification system for the periodic error of the photoelectric range finder includes a guide rail 2, a distance measuring reflective prism 1, and a detection pier 3 for placing the photoelectric range finder. The distance measuring reflective prism 1 is placed on the guide rail 2 according to the interval required for periodic error detection. Above; the photoelectric distance meter periodic error automatic verification system also includes a control box and a computer, and the distance measuring reflective prism 1 is an automatic prism; the computer is connected to the control box, and the control box controls the automatic prism and the photoelectric distance meter to be tested. The guide rail 2 is a large-span reinforced concrete T-beam, which is characterized by a simple structure, better resistance to deformation and deflection. The placement of the electric prism group is based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com