Layered separated mining technology with extremely-thick coal seam continuous miner and filling combined

A technology of extra-thick coal seam and continuous miner, which is applied in the direction of filling, special mining, surface mining, etc., and can solve the problems that it is impossible to arrange conventional fully mechanized mining top coal caving or fully mechanized mining face with large mining height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

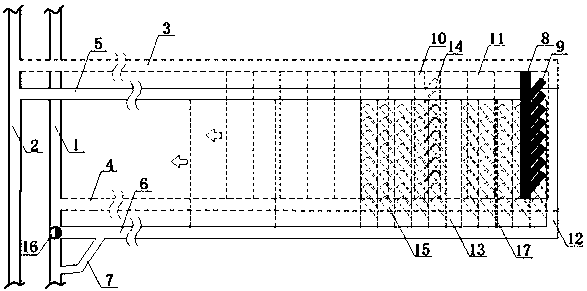

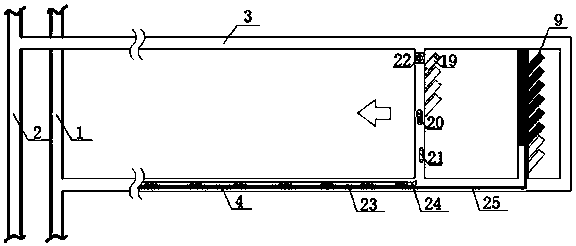

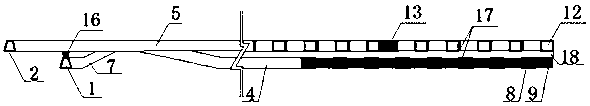

[0024] The roadway excavation sequence of the present invention is as follows: the first excavation completes the transportation roadway 1 and the auxiliary transportation roadway 2 serving the entire coal seam mining, forming an overall transportation system and ventilation system;

[0025] The next layered excavation sequence:

[0026] (1) After the excavation of the transportation roadway 1 and the auxiliary transportation roadway 2 is completed, the layered auxiliary transportation channel 3 is excavated in the auxiliary transportation roadway 2;

[0027] (2) Excavate a lower layer branch roadway after the lower layer auxiliary transport channel 3 is excavated to the predetermined position;

[0028] (4) After the length of the branch road to be excavated reaches 60-120m, the lower stratified main transport channel 3 can be excavated, and at this time, the lower stratified auxiliary transport channel 3 and the lower stratified main transport channel 4 can be simultaneously ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com