Lifting platform with automatic moving rail

A lifting platform and self-propelled technology, which is applied in the field of elevators, can solve the problem of not being able to cross a higher height, and achieve the effect of convenient operation and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

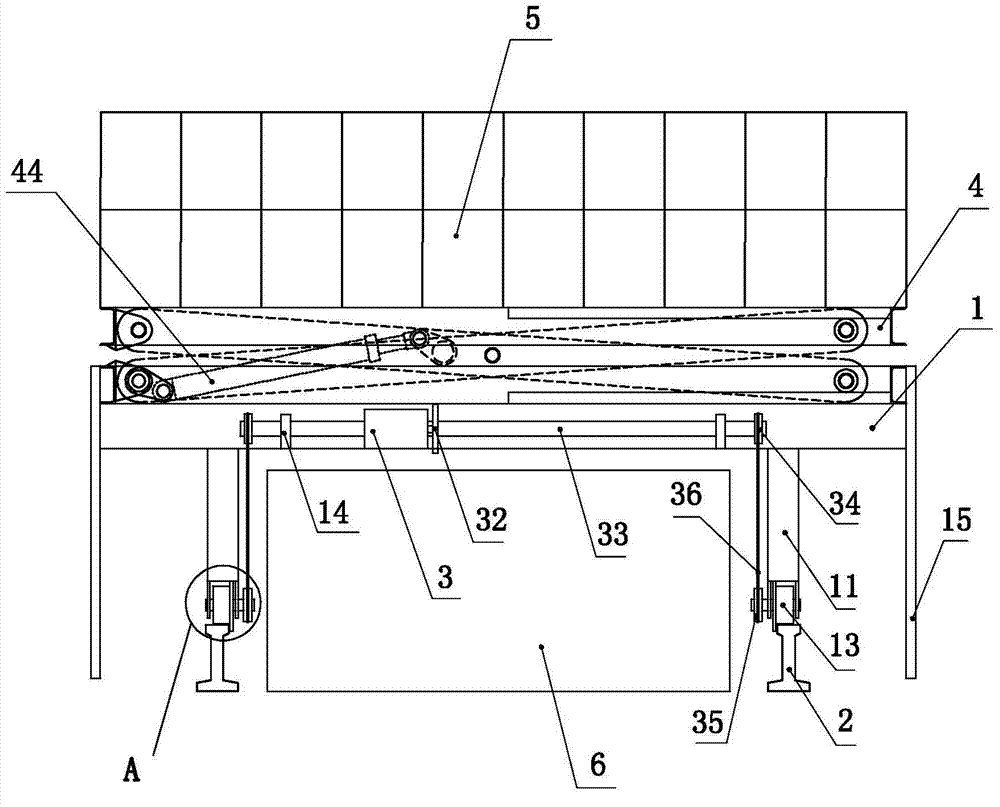

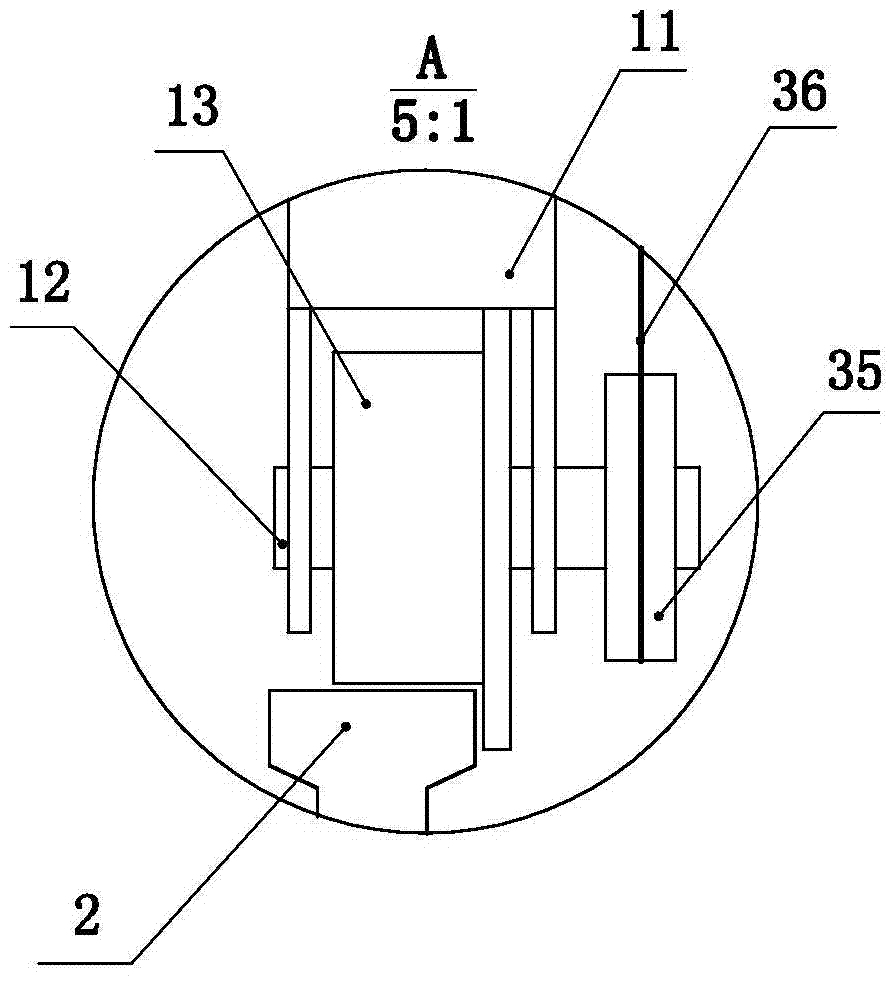

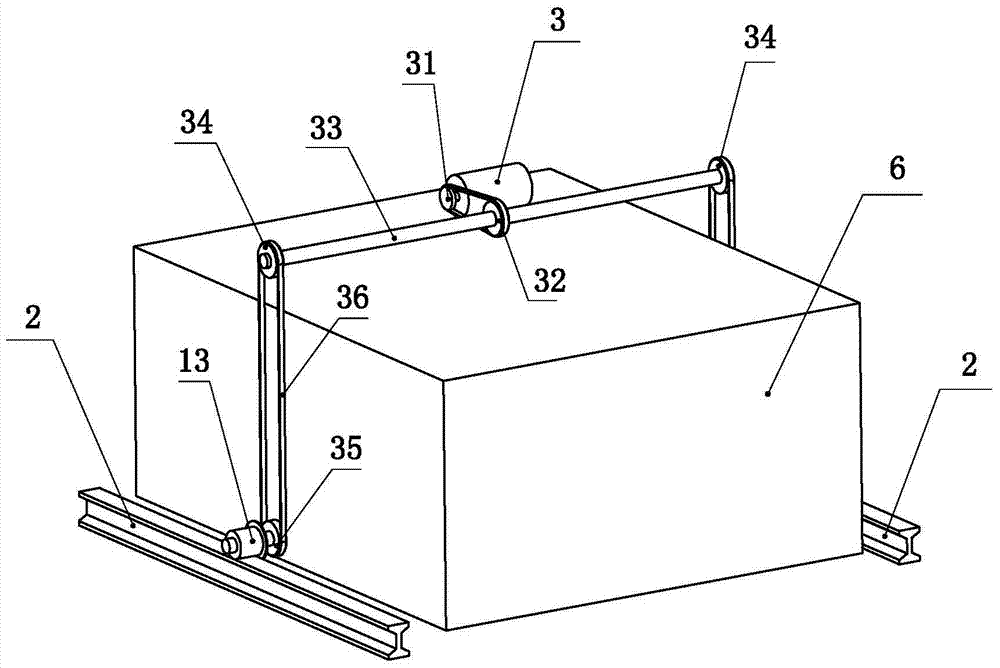

[0021] Such as Figure 1 to Figure 5 Shown, the present invention comprises base 1, supporting leg 11, track wheel shaft 12, track wheel 13, protective plate 15, track 2, motor 3, driving sprocket 31, driven sprocket 32, rotating shaft 33, upper sprocket 34, Lower sprocket 35, top plate 4, first support rod 42, second support rod 43, oil cylinder 44, roller 45 and guardrail 5, the present invention is described below in conjunction with accompanying drawing.

[0022] Such as figure 1 As shown, the base 1 is a profile weldment, and four vertically placed legs 11 are fixed on the bottom of the base. The height of the legs should ensure that the bottom of the base is higher than the height of the driving end 6. The drive head is a part of the fixed production line in the workshop. Four legs surround a square, and a track axle 12 is installed at the bottom of each leg, as figure 2 As shown, a track wheel 13 is fixedly installed on the track wheel shaft, and the track wheel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com