Tablet computer screen pasting jig

A tablet computer and screen sticking technology, applied in electrical digital data processing, instruments, digital data processing components, etc., can solve the problems of high error rate, low work efficiency, difficulty, etc., to achieve low error rate, improved production efficiency, Easy to pick and place effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

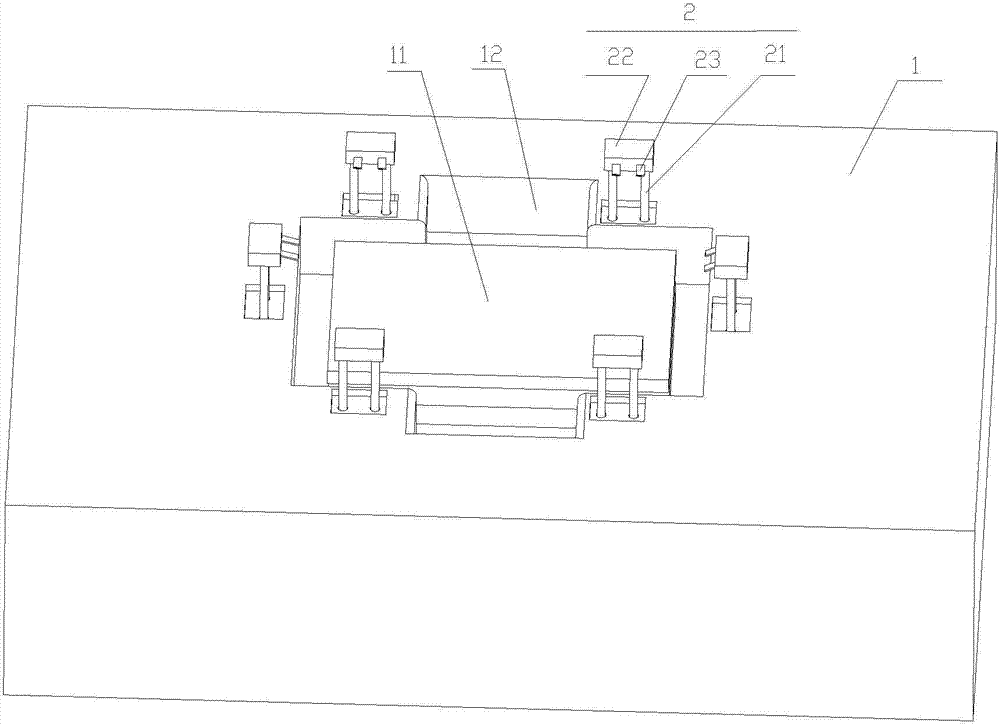

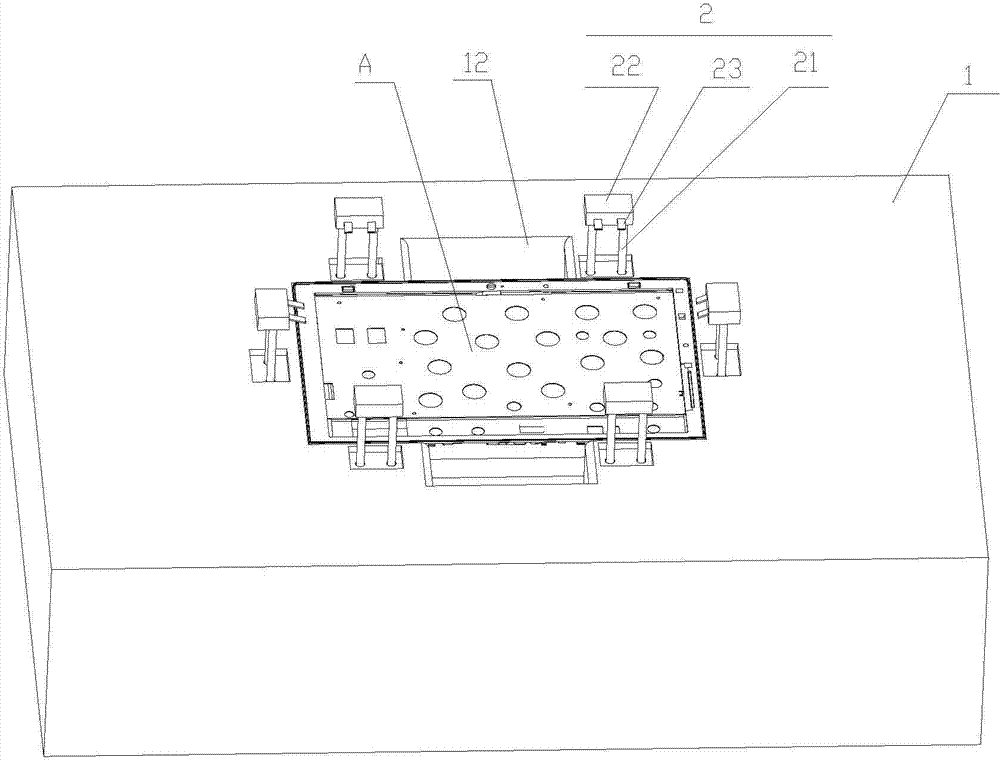

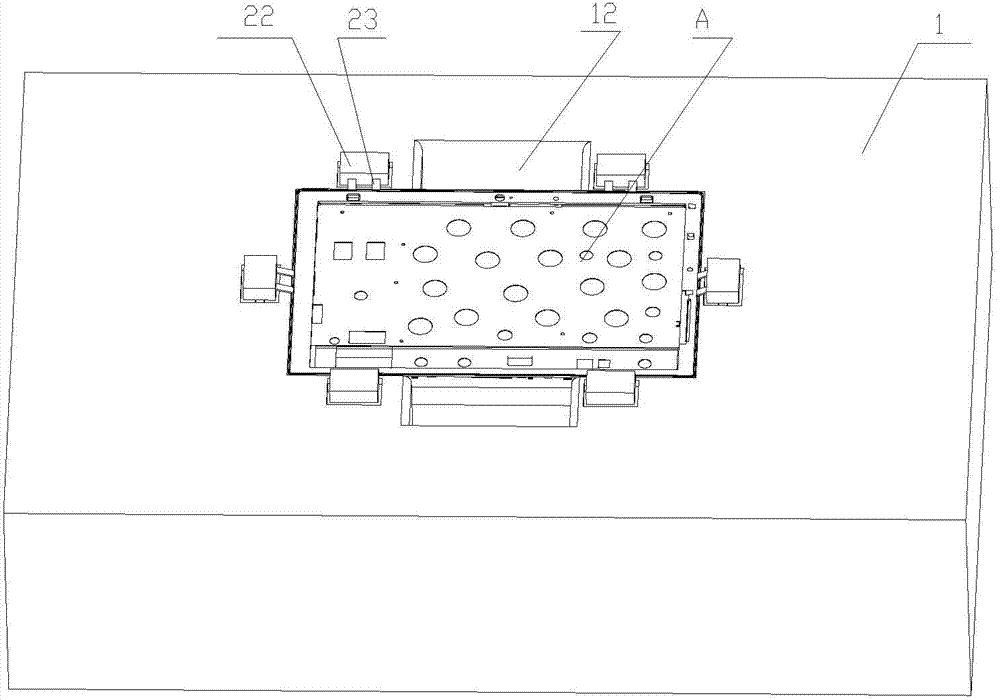

[0024] refer to Figure 1 to Figure 7 , a tablet computer screen attaching jig proposed by the present invention is used for positioning the shell assembly A when attaching the screen, including: a workbench 1, six positioning mechanisms 2 and an ejection device 3.

[0025] The workbench 1 is provided with a positioning slot 11 for placing the housing assembly A. As shown in FIG. The outer periphery of the positioning groove 11 is provided with a relief groove 12 communicating with the positioning groove 11, so as to facilitate the installation and unloading of the shell assembly A.

[0026] The positioning mechanism 2 includes a guide post 21, a positioning block 22, an elastic piece 23 and a second driving mechanism. The positioning block 22 is mounted on the workbench 1 through the guide post 21 to move up and down, and is distributed on the periphery of the positioning groove 11 . Each positioning block 22 is provided with no less than one elastic piece 23 , and in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com