Novel packing machine

A new type of strapping technology, applied in the field of strapping machines, can solve problems such as difficult pre-adjustment of pressure, heavy weight, and excessive tension of strapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

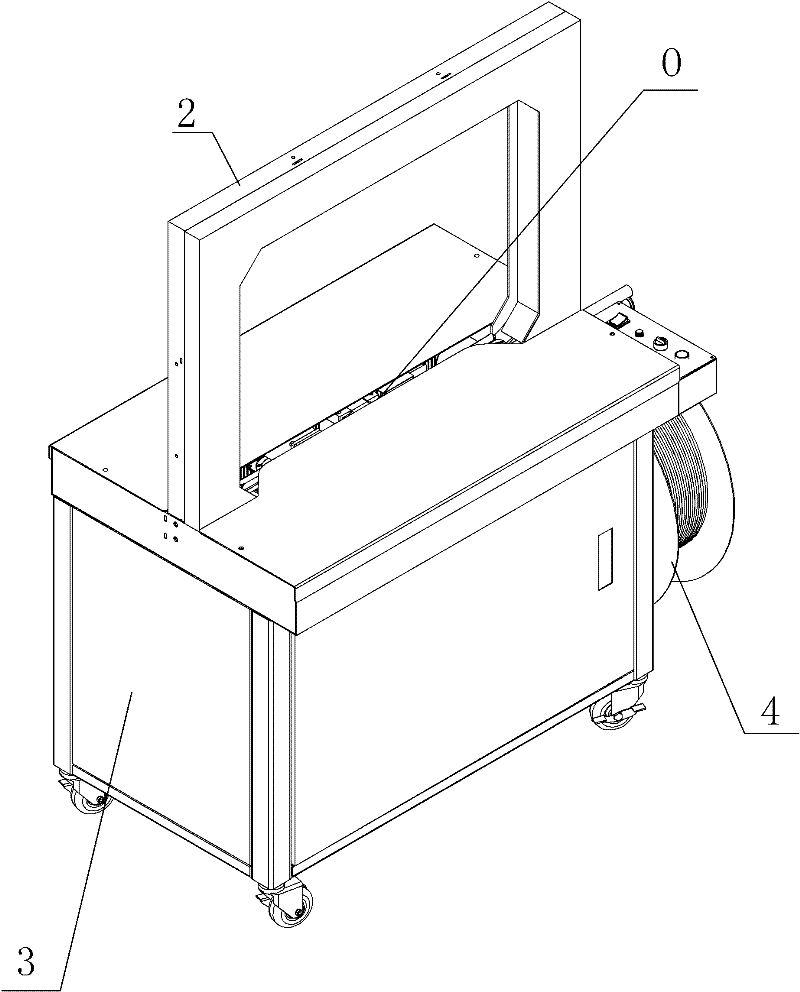

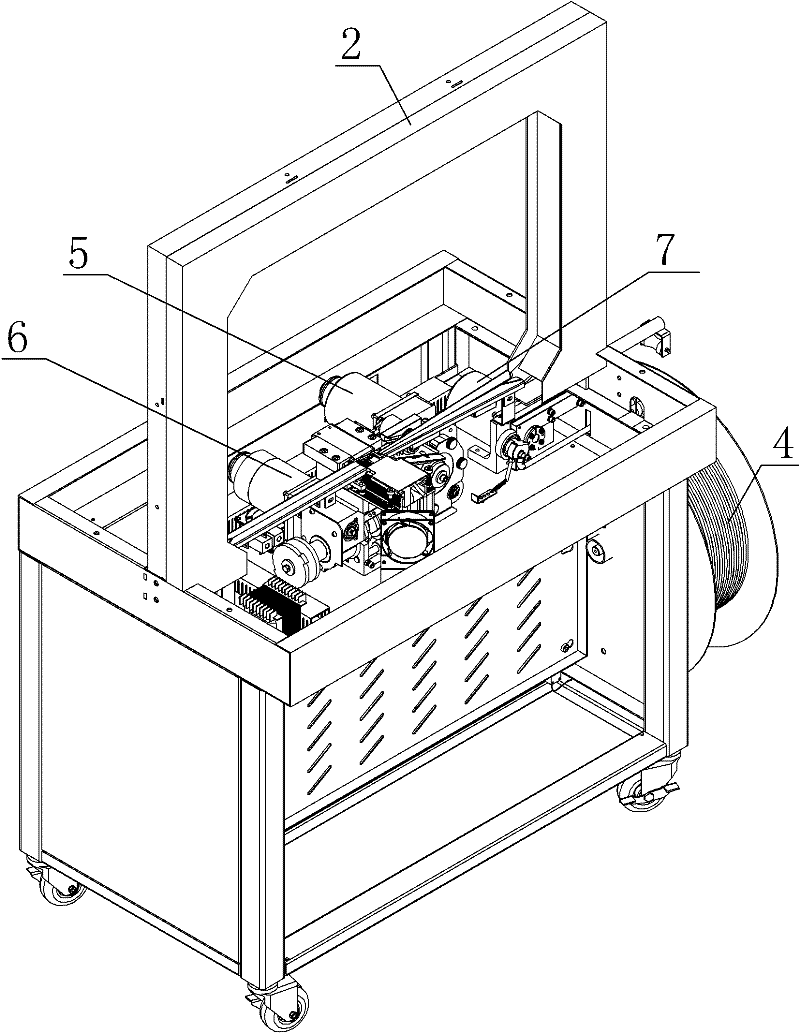

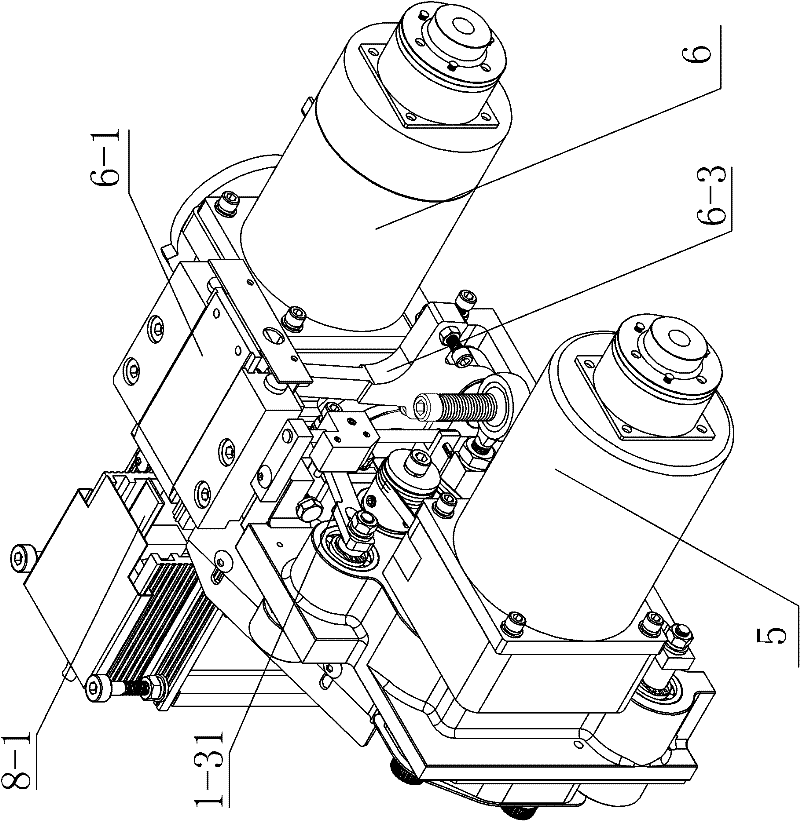

[0070]With reference to accompanying drawing, baler provided by the present invention, its lower half is provided with vertical mounting plate 1, and the top of vertical mounting plate 1 is fixed with horizontal mounting plate 9, and its lower half is provided with vertical mounting plate 1, Its upper part is provided with fixed frame body 2, and fixed frame body surrounds the left and right sides and the top of item binding station O, and described installation plate 1 and fixed frame body 2 are installed on the baler frame 3, on the baler The bottom is also provided with a tape reel 4; on the horizontal mounting plate 9, a baler core and a pre-feeding belt device are installed, and the baler core is provided with a sending and unwinding belt and a tensioning belt device, and a sending and unwinding belt and a tensioning belt device Including feeding and unwinding belt mechanism and tensioning belt mechanism

[0071] refer to Figure 1-8 . Described sending back belt mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com