A piezoelectric ceramic diaphragm pump

A technology of piezoelectric ceramics and piezoelectric ceramic tubes, which is applied in the field of piezoelectric ceramic diaphragm pumps, can solve the problems of incompatibility of high-frequency characteristics of piezoelectric elements and low-frequency characteristics of valves, and achieve the requirements of simple structure and driving mode and low ideality , The effect of reducing the loss of vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

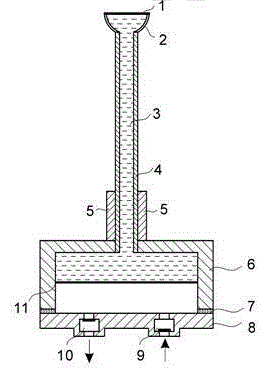

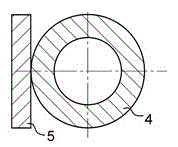

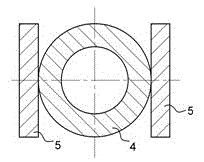

[0069] The specific manufacturing process and driving method of the piezoelectric ceramic diaphragm pump of the present invention are described by using two piezoelectric chip vibrators and a circular metal tube as a typical example.

[0070] The piezoelectric sheet 501 has a length of 20 mm, a width of 5 mm, and a thickness of 1 mm. Use conductive glue or electric soldering iron to fix the wire on the electrode of the piezoelectric sheet 501, and the fixed position shall be as close to the edge of the fixed end of the piezoelectric sheet 501 as possible, so as not to affect the consolidation of the piezoelectric sheet and the metal tube and the system vibration Mainly. The piezoelectric sheet 501 is placed in 80-degree silicon oil for polarization, and the polarization voltage is 2000 V / mm for 20 minutes. The polarized piezoelectric sheet 501 is cleaned with alcohol or other cleaning agents. The rubber diaphragm 11 is adhered to the cavity of the upper cover 6 of the pump cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com