Gravitational potential energy recycling and reutilization energy-saving device based on four-port hydraulic transformer

A technology of hydraulic transformers and energy-saving devices, which is applied to earth movers/excavators, construction, etc., which can solve the problems of hydraulic oil quality deterioration, waste of energy, and low recovery efficiency, and achieve the effect of less modification and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

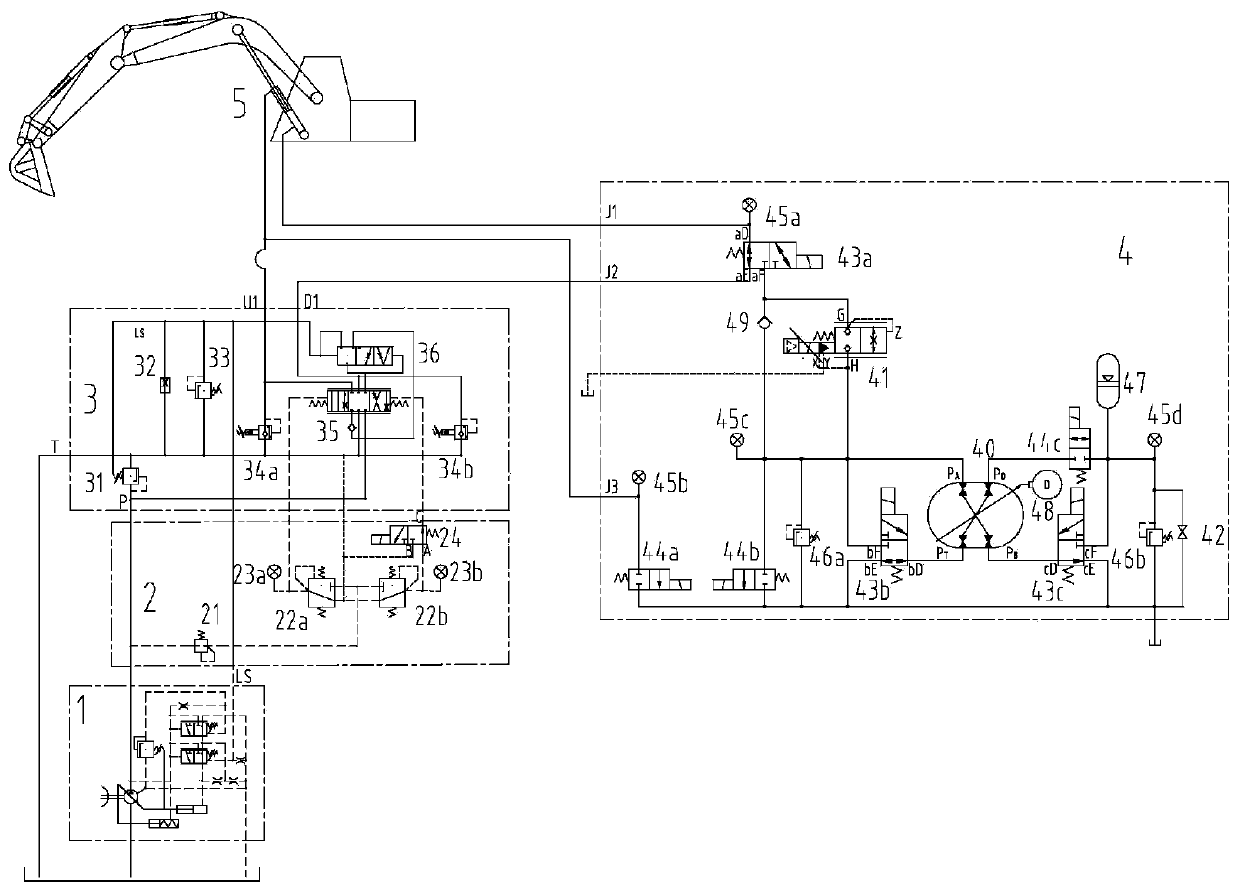

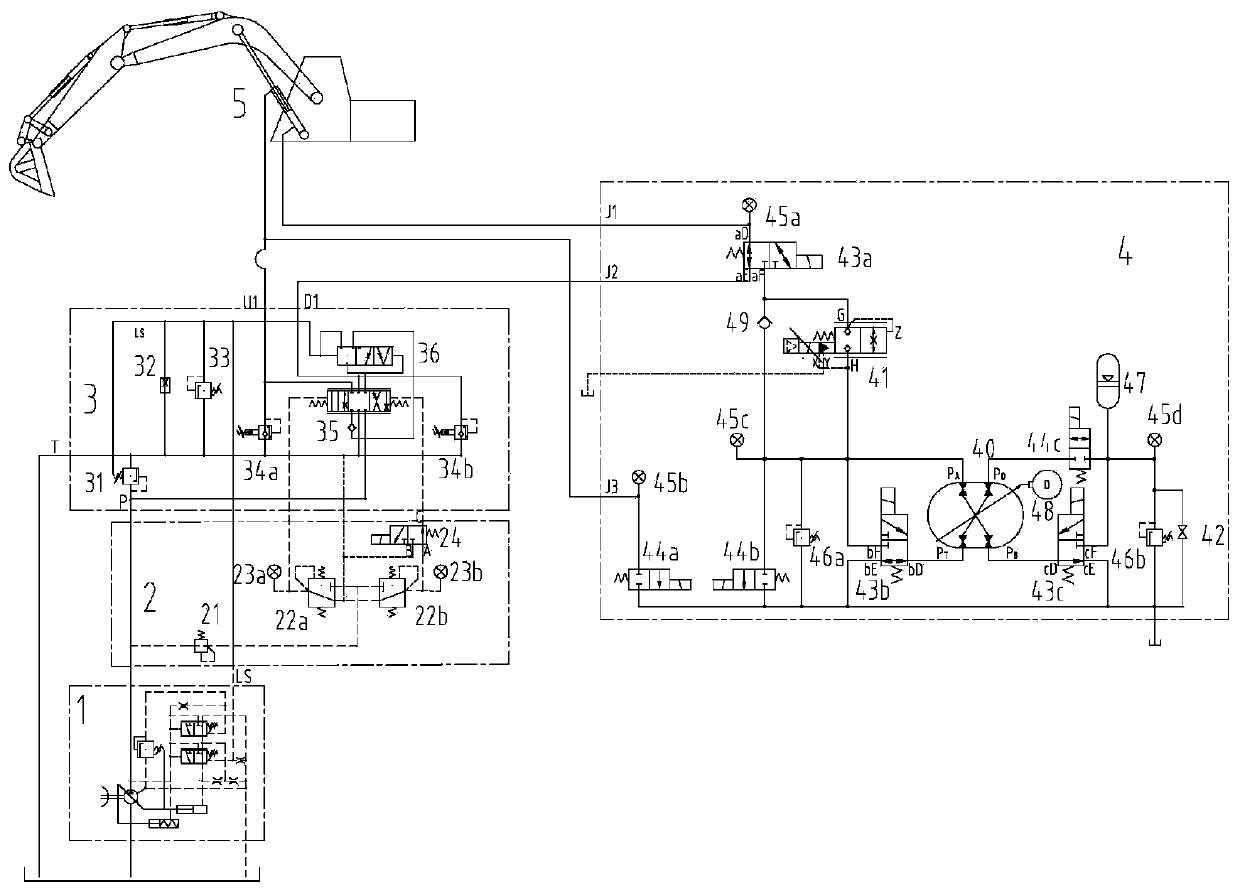

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the present invention is a gravitational potential energy recovery and reuse energy-saving device based on a four-port hydraulic transformer, including a load-sensitive hydraulic pump 1, a pilot control valve block 2, a main control valve block 3, an energy-saving device 4 and a boom cylinder 5. Since the present invention only considers the recovery of hydraulic excavator arm potential energy, so in figure 1 The hydraulic circuits such as the arm cylinder, bucket cylinder, and travel motor of the excavator are not reflected in the figure 1 Except for the energy-saving device 4, the pressure sensor 23a, the pressure sensor 23b and the electromagnetic reversing valve 24, the hydraulic system is all existing in the original hydraulic system of the excavator, and the composition and function of the existing matu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com