Patents

Literature

63results about How to "Realize the goal of energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

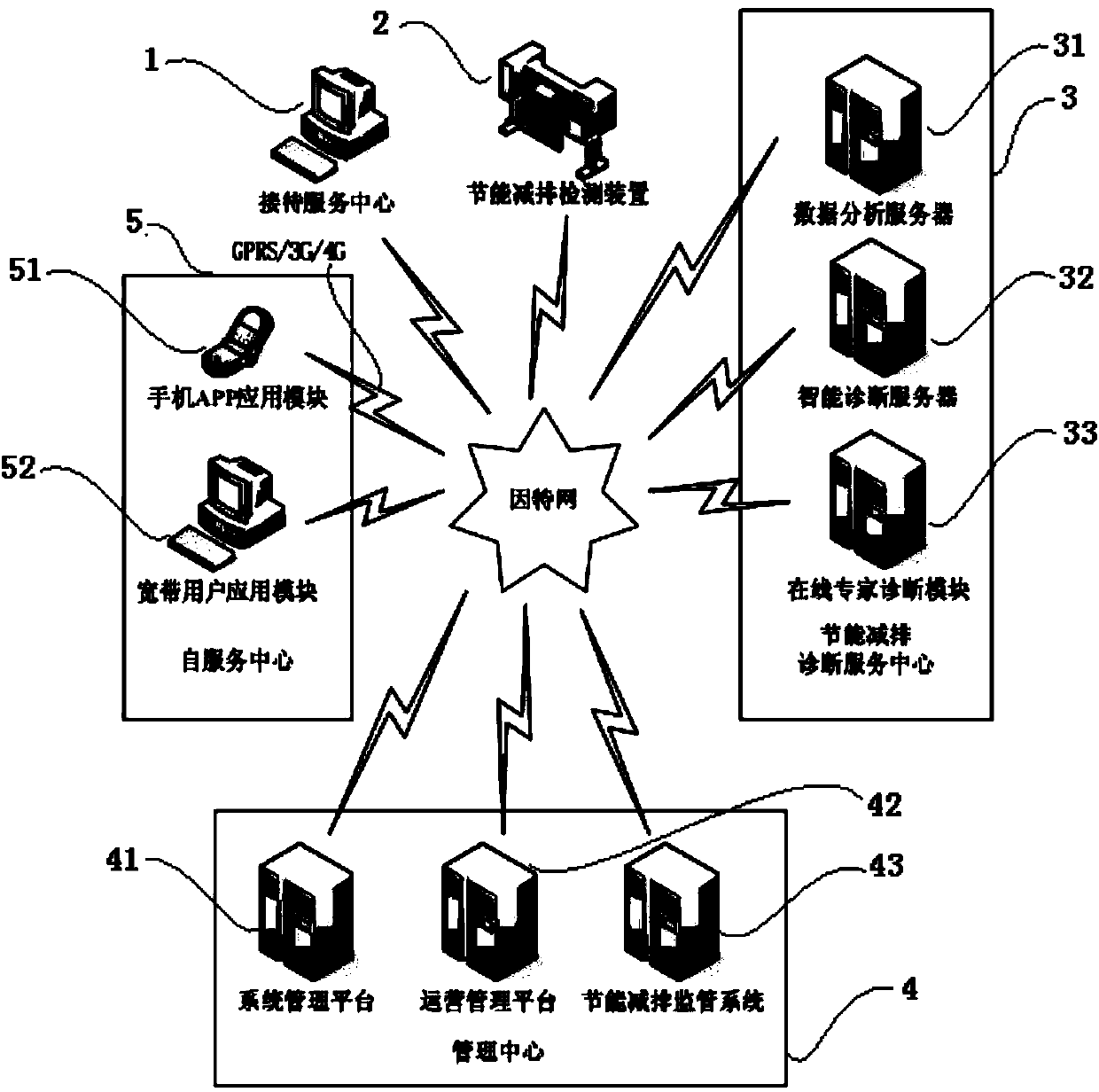

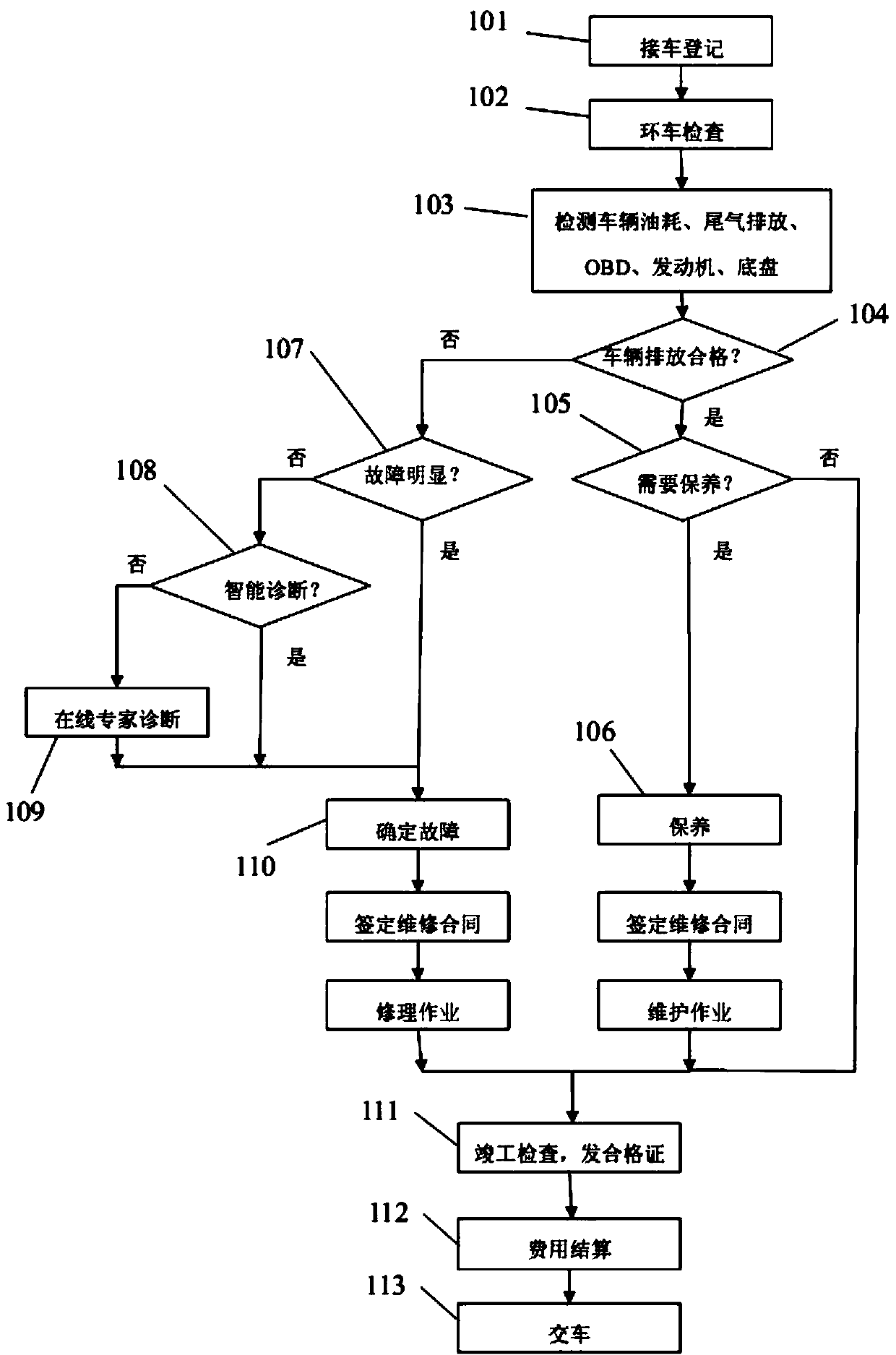

Automatic diagnosing system for energy conservation, emission reduction and repair of automobile

ActiveCN104199436APromote energy-saving technologiesReduce disassemblyElectric testing/monitoringIntelligent NetworkDiagnostic system

The invention provides an automatic diagnosing system for energy conservation, emission reduction and repair of an automobile. The system comprises an energy conservation and emission reduction detecting device, and an energy conservation and emission reduction diagnosing service center, wherein the energy conservation and emission reduction detecting device comprises an oil consumption detecting module, a tail gas emission detecting module, an OBD detecting module, an engine detecting module and a basis system detecting module, and is used for detecting energy conservation and emission reduction data comprising the oil consumption and the tail gas emission of the automobile so as to generate the detected data to be transferred to the energy conservation and emission reduction diagnosing service center to be processed; and the energy conservation and emission reduction diagnosing service center comprises a data analysis server, an intelligent diagnosis server, an on-line expert diagnosing module and an assisting server. The system can be applied to the comprehensive detection for the superscalar positions of the automobile and the intelligent network bug diagnosis, so that maintenance technicians can accurately repair and maintain in time, the unnecessary dismounting for the automobile is reduced, the energy-saving technology of the automobile is promoted, the consumption of the fuel and the discharge amount of the pollutants for the automobile are reduced, and the purposes of energy conservation and emission reduction are realized.

Owner:广西三原高新科技有限公司

Formula and production process of dairy cow protein particle feed

InactiveCN101731485AImprove utilization efficiencyIncrease expansionAnimal feeding stuffFiberAntioxidant

The invention relates to a formula of dairy cow protein particle feed which comprises the following components by weigh percent: 15-40 percent of energy feed, 40-80 percent of protein feed, 0-9 percent of oil and fat, 0-18 percent of amino acid, 0-2.3 percent of vitamin, 1.6-2 percent of calcium carbonate, 0-1 percent of adhesive, 0-0.1 percent of antioxidant and 0-0.3 percent of antimold agent. The production process of the dairy cow protein particle feed comprises the following steps: a, weighting the components according to the weight percent thereof; b, grinding the components; c, mixing the ground components; d, tempering the mixture; e, granulating the mixture; f, post-curing the granules; g, drying the granules; and h making the granules into the dairy cow protein particle feed which has the diameter of less than 4 mm and the length of 1 to 2 times of the diameter and contains the dry matter of more than 88 percent. The dry matter contains the crude protein of more than 20 percent and the crude fiber of less than 18 percent. The dairy cow protein particle feed can be kept stable in water for more than 5 min and has the dispersion rate of less than 12 percent in water. The protein in the dairy cow protein particle feed is less degraded by the rumen microorganisms, the rumen bypass efficiency of the protein is improved, the need of the essential amino acids in the nutrient of protein in the dairy cow body is balanced, the efficiency of using the dairy cow protein particle feed by the dairy cow is increased, the health status of the dairy cow body is improved and the pollution of the nitrogen in the excrement of the dairy cow to the environment is reduced.

Owner:ZHEJIANG KESHENG FEED CO LTD

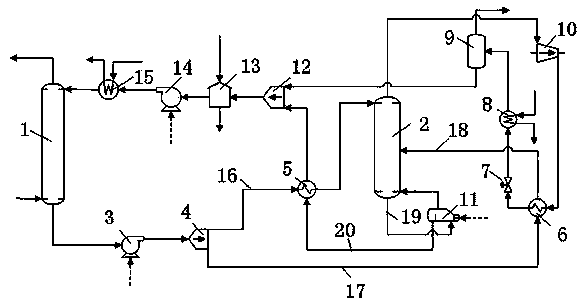

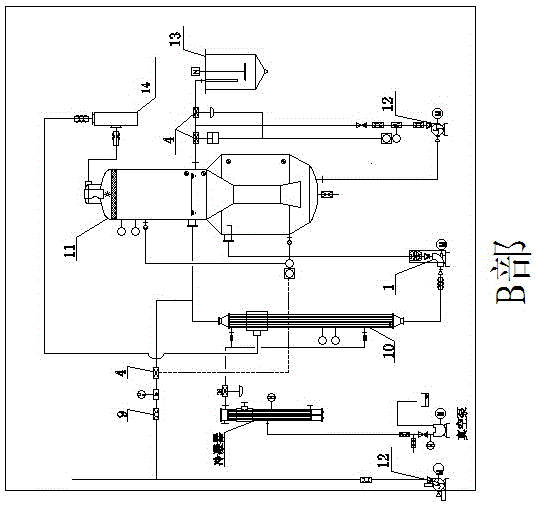

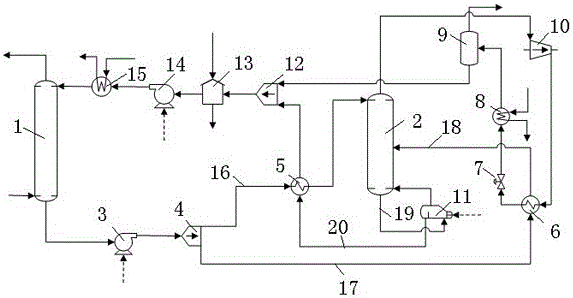

Technology for separating and recovering carbon dioxide from industrial tail gas

ActiveCN103463955AReduce energy consumptionRealize the goal of energy saving and emission reductionProductsCarbon compoundsWater vaporProcess engineering

The invention discloses a technology for separating and recovering carbon dioxide from industrial tail gas, which mainly adopts an energy high-integration means-heat pump rectification technology. The technology comprises the steps that the pretreated industrial tail gas enters the bottom of an absorption tower and is in countercurrent contact with the absorption liquid entering from the top of the absorption tower to obtain rich liquid; the rich liquid passes through a rich liquid pump and then is divided into two parts through a splitter, wherein the first part of the rich liquid enters from the top of a desorption tower by spraying, the second part of the rich liquid enters the desorption tower from the lower middle part of the desorption tower to be desorbed, and the desorbed carbon dioxide with a little water vapor is discharged from the top of the desorption tower; the barren liquid after the desorption exchanges heat with the first part of the rich liquid and then is cooled by a barren liquid cooler before entering the absorption tower from the top of the absorption tower to be recycled. Based on the traditional carbon dioxide trapping technology, the technology disclosed by the invention integrates the distribution desorption and heat pump rectification technology, effectively utilizes the latent heat of vapor at the top of the desorption tower, and greatly reduces the energy consumption in a system operation process; moreover, with simple flow and low operation cost, the technology also can obtain a high-purity carbon dioxide product so as to reduce the greenhouse gas emission.

Owner:HUNAN UNIV

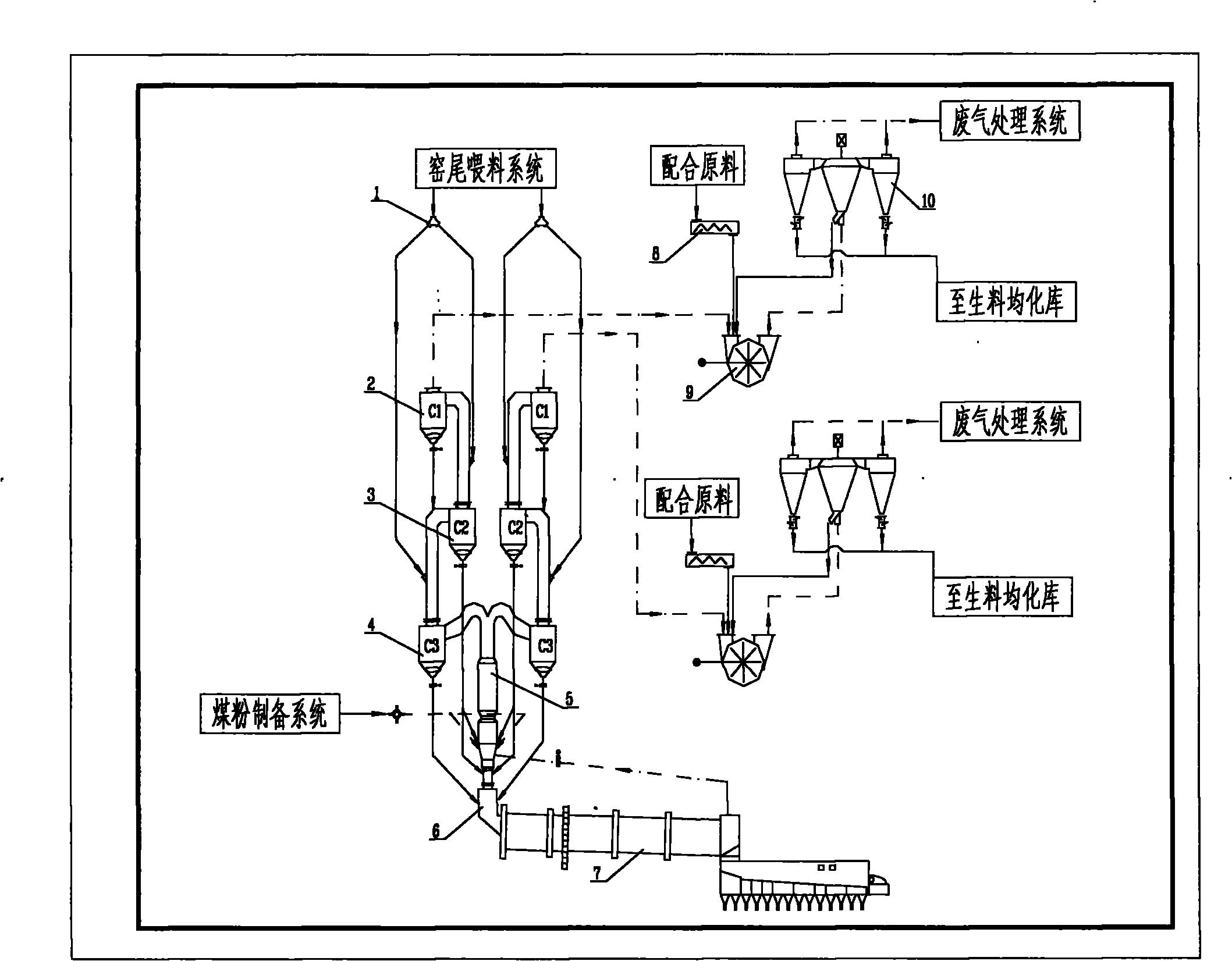

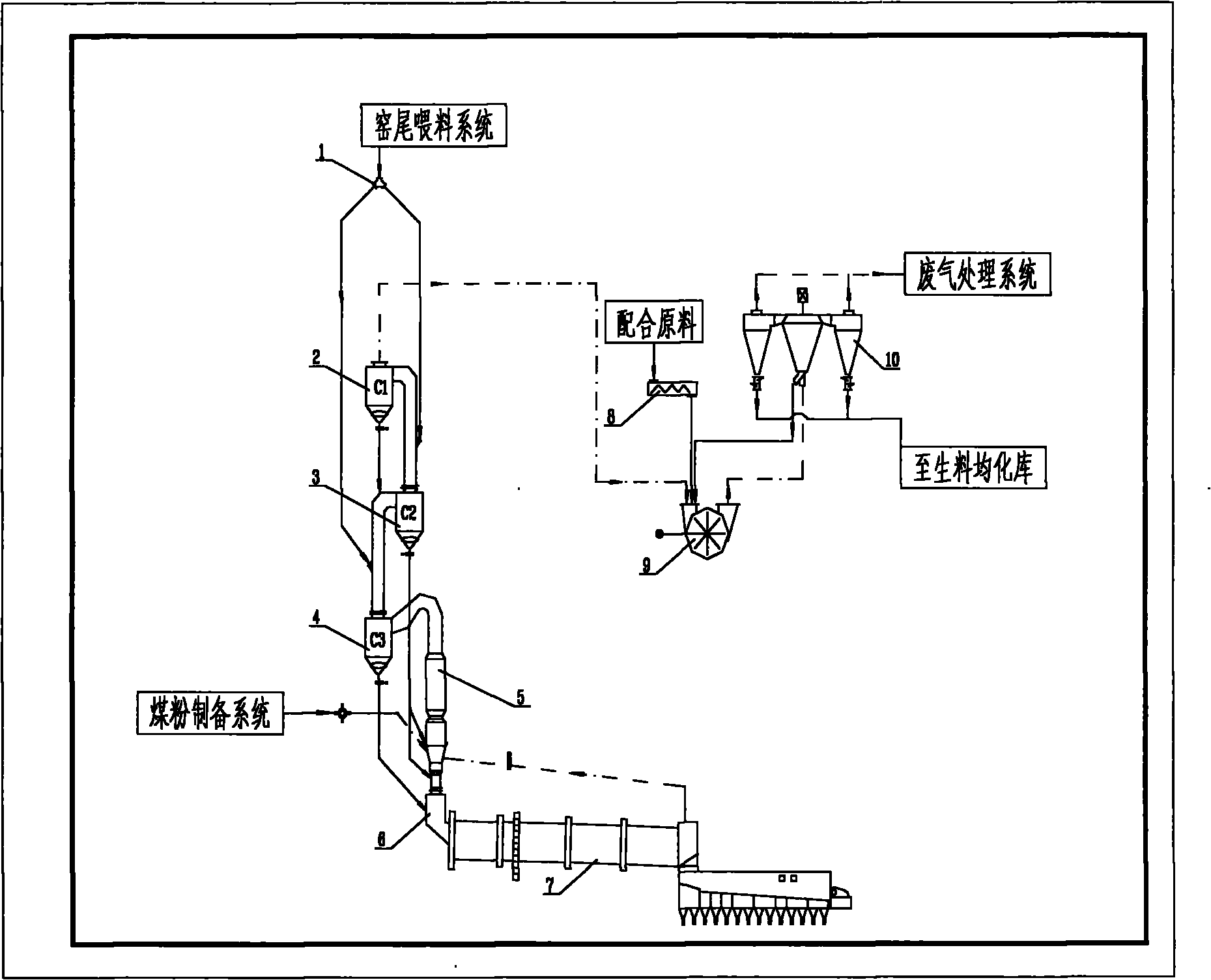

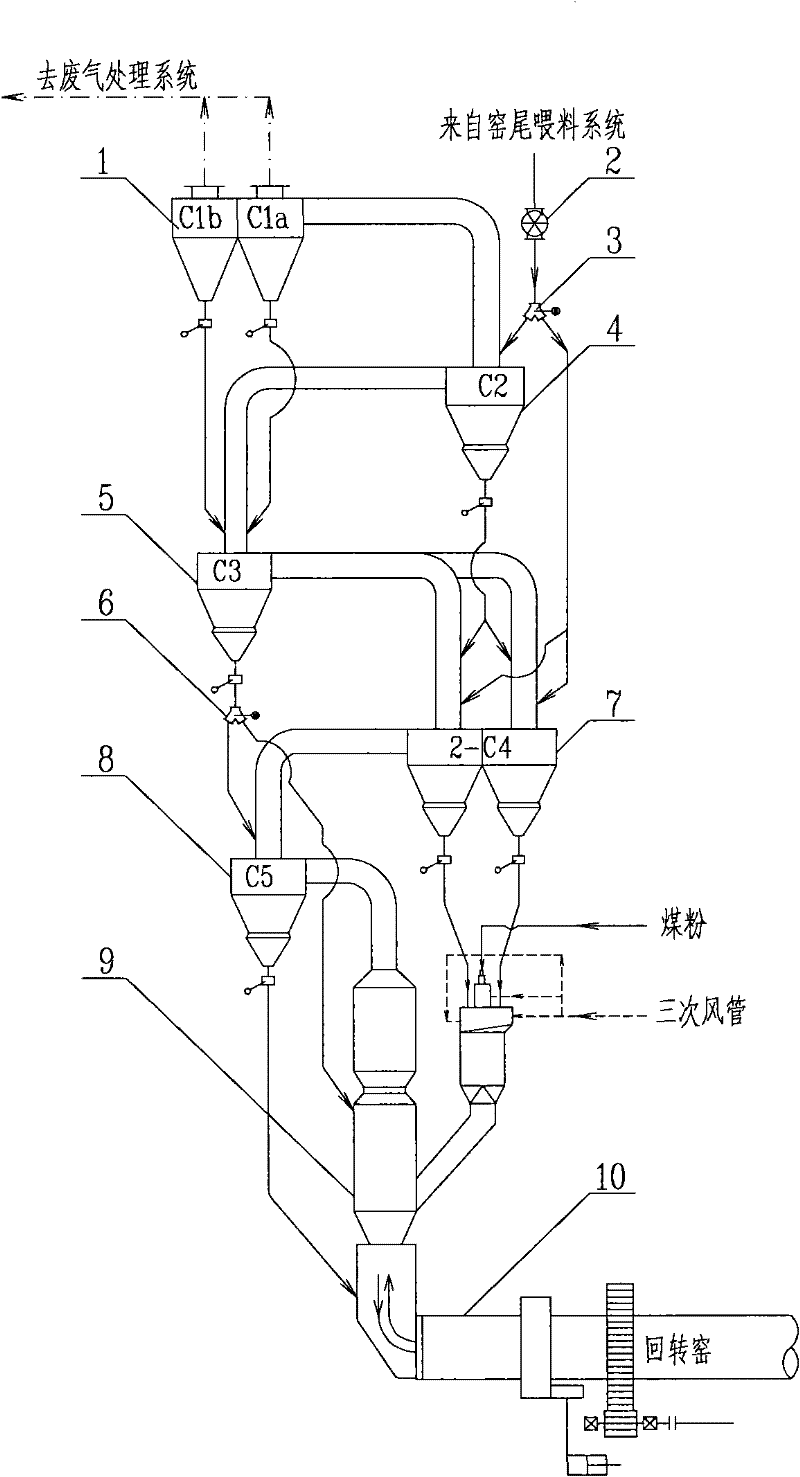

Method for producing cement clinker by calcining chalk

ActiveCN101811839AEmission reductionImprove protectionClinker productionProcess systemsMetallic materials

The invention relates to a method for producing cement clinker by calcining chalk, which belongs to the technical field of inorganic nonmetallic materials. The invention takes high moisture content chalk (moisture content of 20-35%) as calcareous raw materials, and is characterized by adopting a dry pre-heating and pre-decomposing technique to calcine the cement clinker, and realizing the organicintegration of three process systems of a raw material drying preparation system, a pre-heating and pre-decomposing system and a clinker calcination system. The method comprises the following steps: (1) the raw material drying preparation system: a drying crusher and a powder concentrator are adopted to dry and sort the prepared chalk raw materials; (2) the pre-heating and predecomposing system: a cyclone preheater and a decomposing furnace system are adopted to preheat and pre-decompose the chalk raw materials, wherein the outlet temperature (600-750 DEG C) of the preheater is adjustable; and (3) the cement clinker calcination system: the predecomposed raw materials enter a rotary kiln system to be calcined into the cement clinker. The invention has the advantages of low comprehensive energy consumption, stable production capacity, high system operation rate and the like.

Owner:成都建筑材料工业设计研究院有限公司

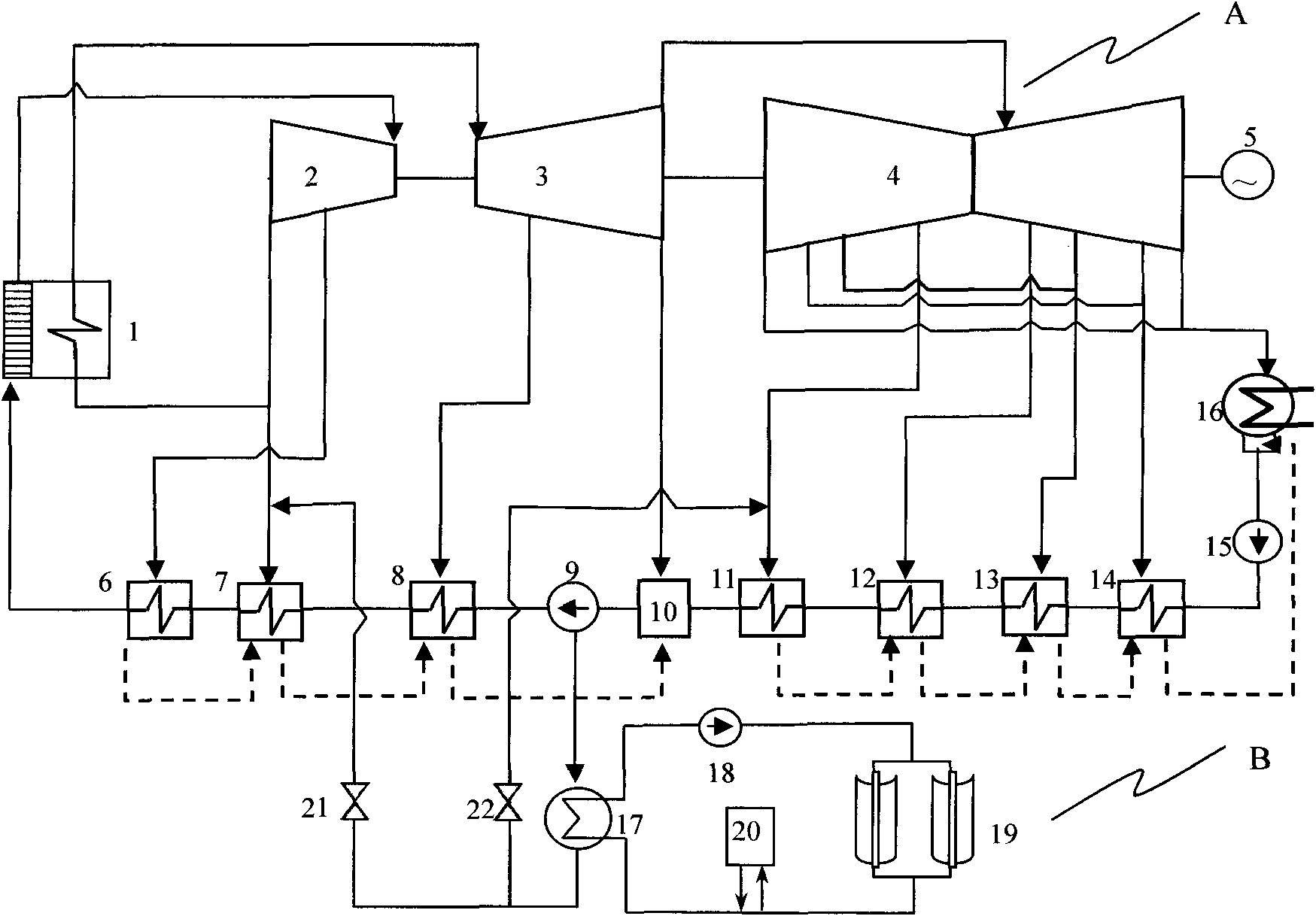

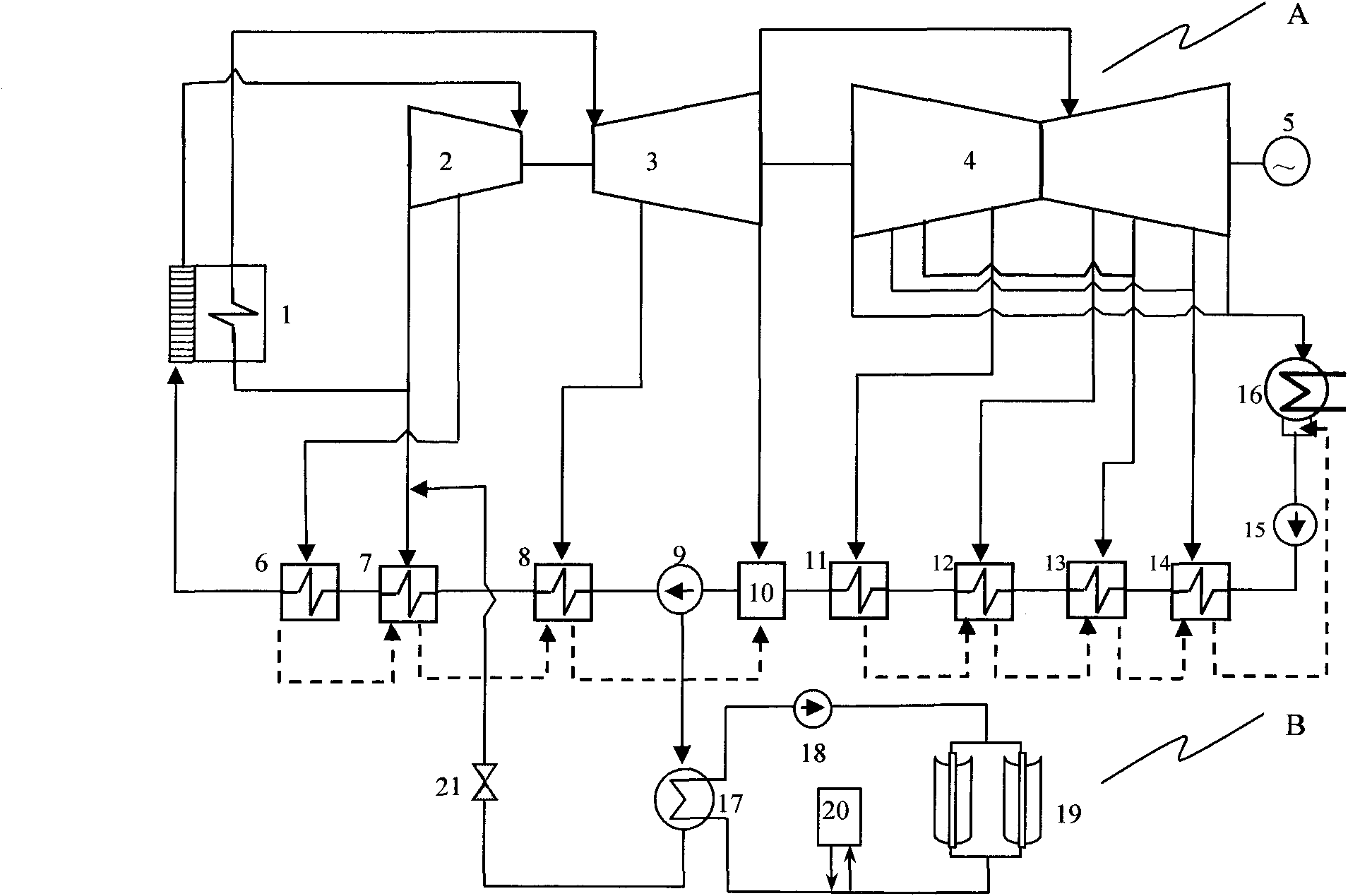

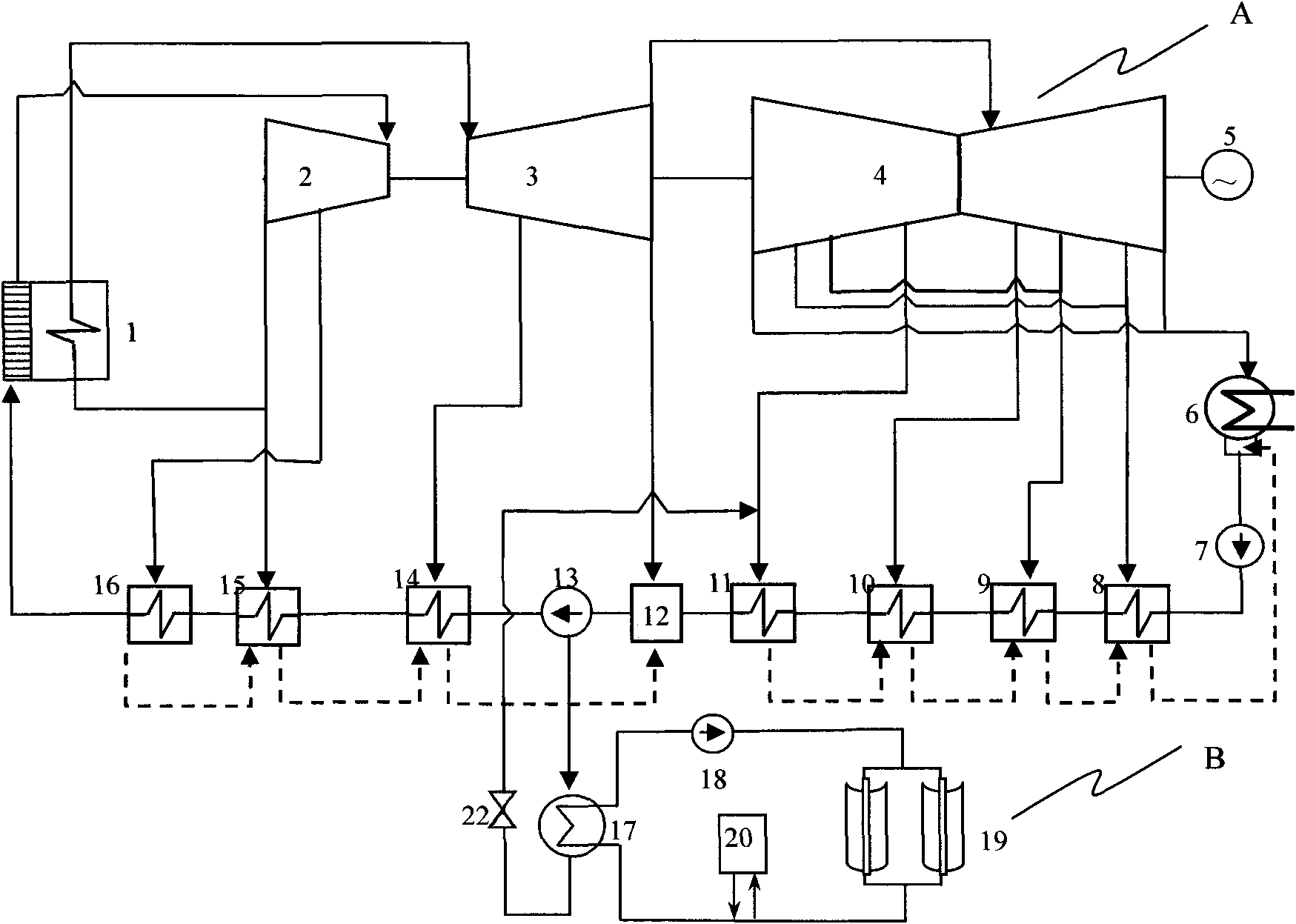

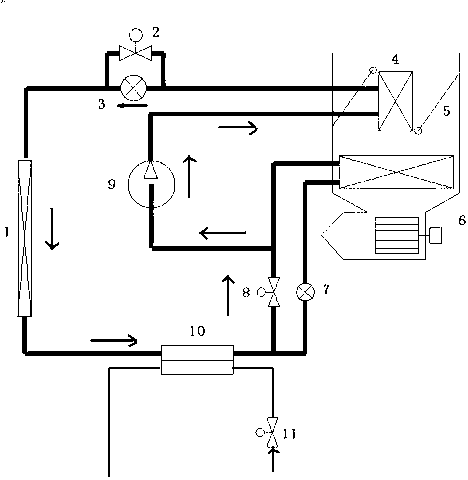

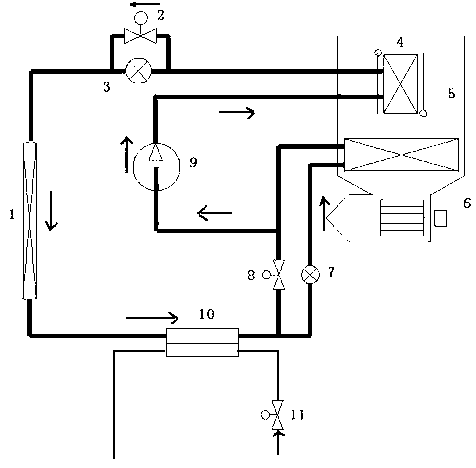

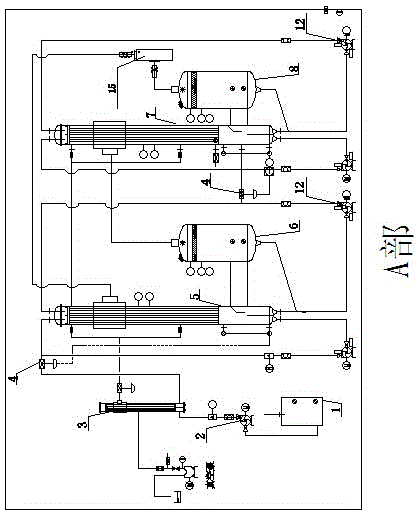

Solar heat collection, energy storage and back heating system applied to thermal generator set

InactiveCN101846044ARealize the goal of energy saving and emission reductionReduce regenerative steam extractionSteam generation heating methodsFrom solar energyClosed loopEngineering

The invention discloses a solar heat collection, energy storage and back heating system applied to a thermal generator set, and belongs to the field of energy conservation and emission reduction of the thermal generator set. The solar heat collection, energy storage and back heating system provided by the invention is connected with the conventional thermal generator set through a pipeline and a valve. The solar heat collection, energy storage and back heating system consists of a heat exchanger, an oil pump, a solar heat collection field, a heat accumulator and a heat exchanger which are connected in turn in a closed-loop mode; a heating working medium input end of the heat exchanger is connected with a center tap of a water supply pump of the thermal generator set; and a heating working medium input end of the heat exchanger is connected with a certain back heating steam extraction pipeline of the thermal generator set. The system can provide qualified heating steam for a certain back-heat heater through proper valve switching operation without changing a thermodynamic system structure of the conventional thermal generator set to stop using back heating extracted steam of a primary steam turbine so that the generating coal consumption of the thermal generator set is reduced and the purposes of energy conservation and emission reduction of the thermal generator set are fulfilled.

Owner:HUAZHONG UNIV OF SCI & TECH

Electric automobile heating system with heat absorber

InactiveCN102862458ARealize the goal of energy saving and emission reductionReduce consumptionAir-treating devicesVehicle heating/cooling devicesCurrent electricEngineering

The invention discloses an electric automobile heating system with a heat absorber. The electric automobile heating system comprises an outer condenser, an evaporator, a compressor and an inner condenser, wherein the outer condenser, the evaporator, the compressor and the inner condenser are connected in turn, and the inner condenser is connected with the outer condenser; the electric automobile heating system further comprises the heat absorber; one end of the heat absorber is connected with the outer condenser; the other end of the heat absorber is connected with the evaporator and the compressor; and the third end of the heat absorber is connected with a water cooling system which is installed on a power control device of an electric car. With the adoption of the electric automobile heating system with the heat absorber, the low-temperature heat sources on a motor, a PCU and an FCE on the electric car are collected through arranging the heat absorber in the current electric automobile heating system so as to heat the electric car. The electric automobile heating system is simple in structure, and can be conveniently operated; and with the adoption of the electric automobile heating system, the energy consumption of the electric car is greatly reduced, the heating efficiency is improved, and the pollution of the environment is prevented.

Owner:上海双桦工贸有限公司

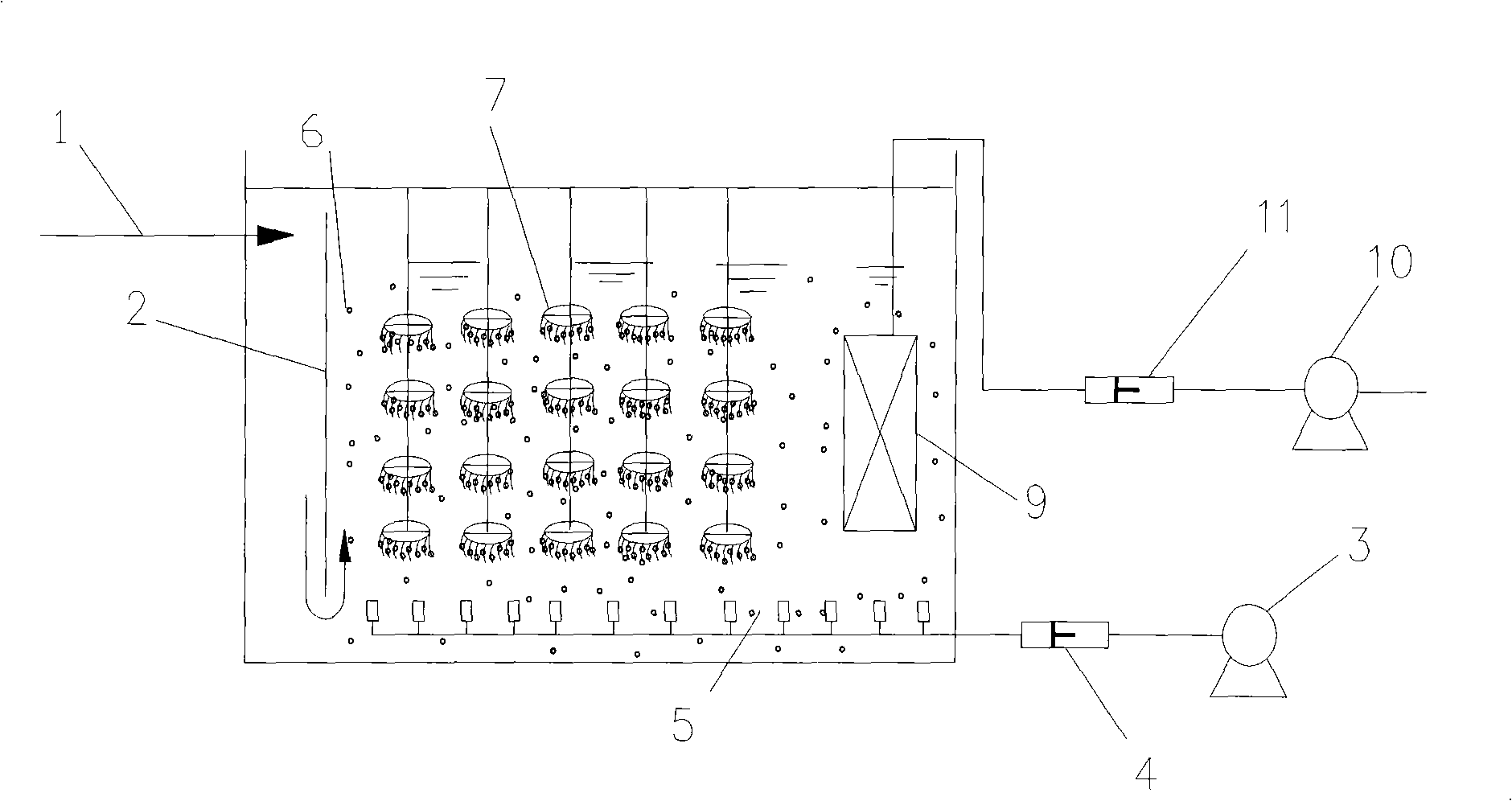

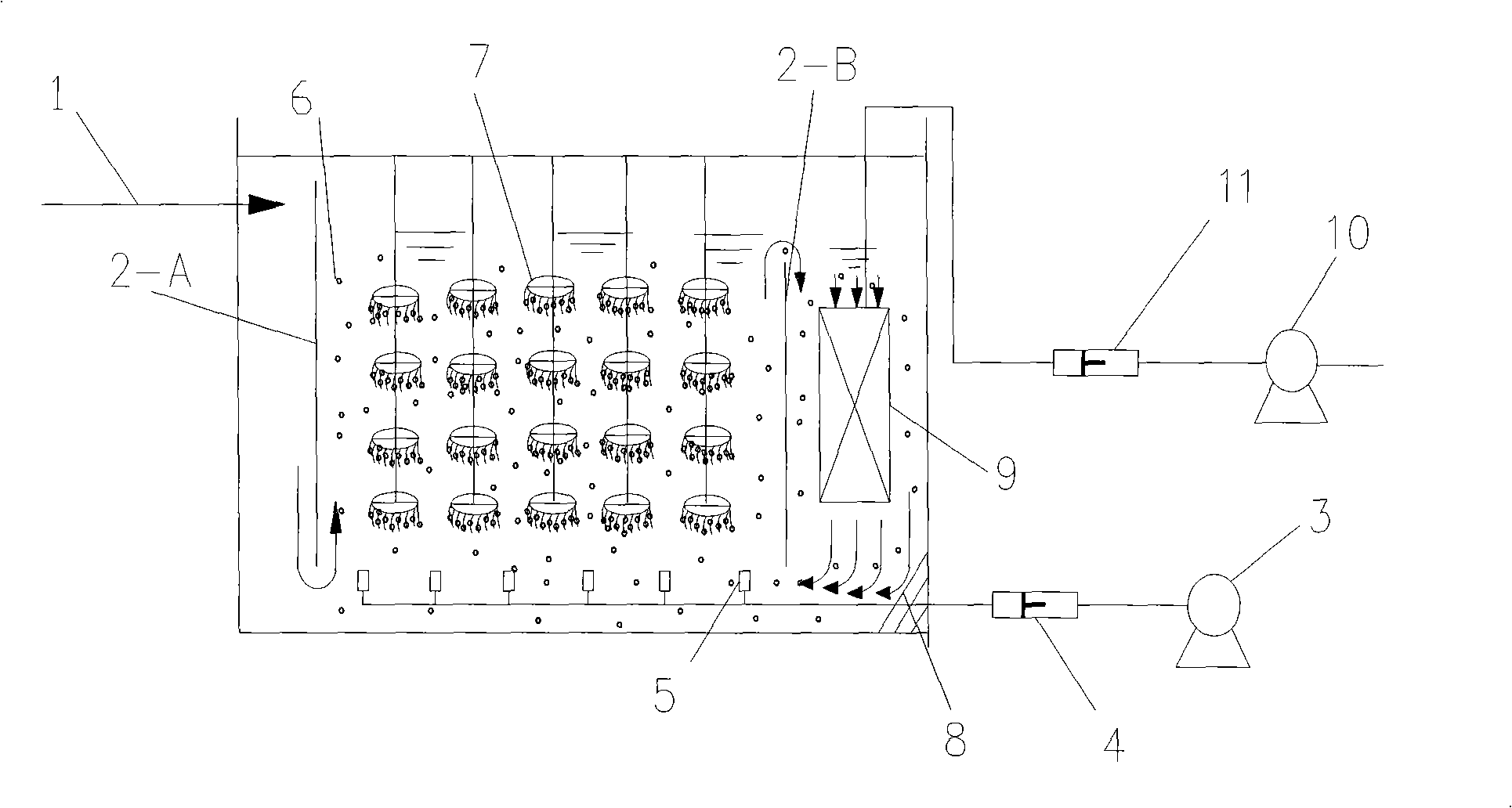

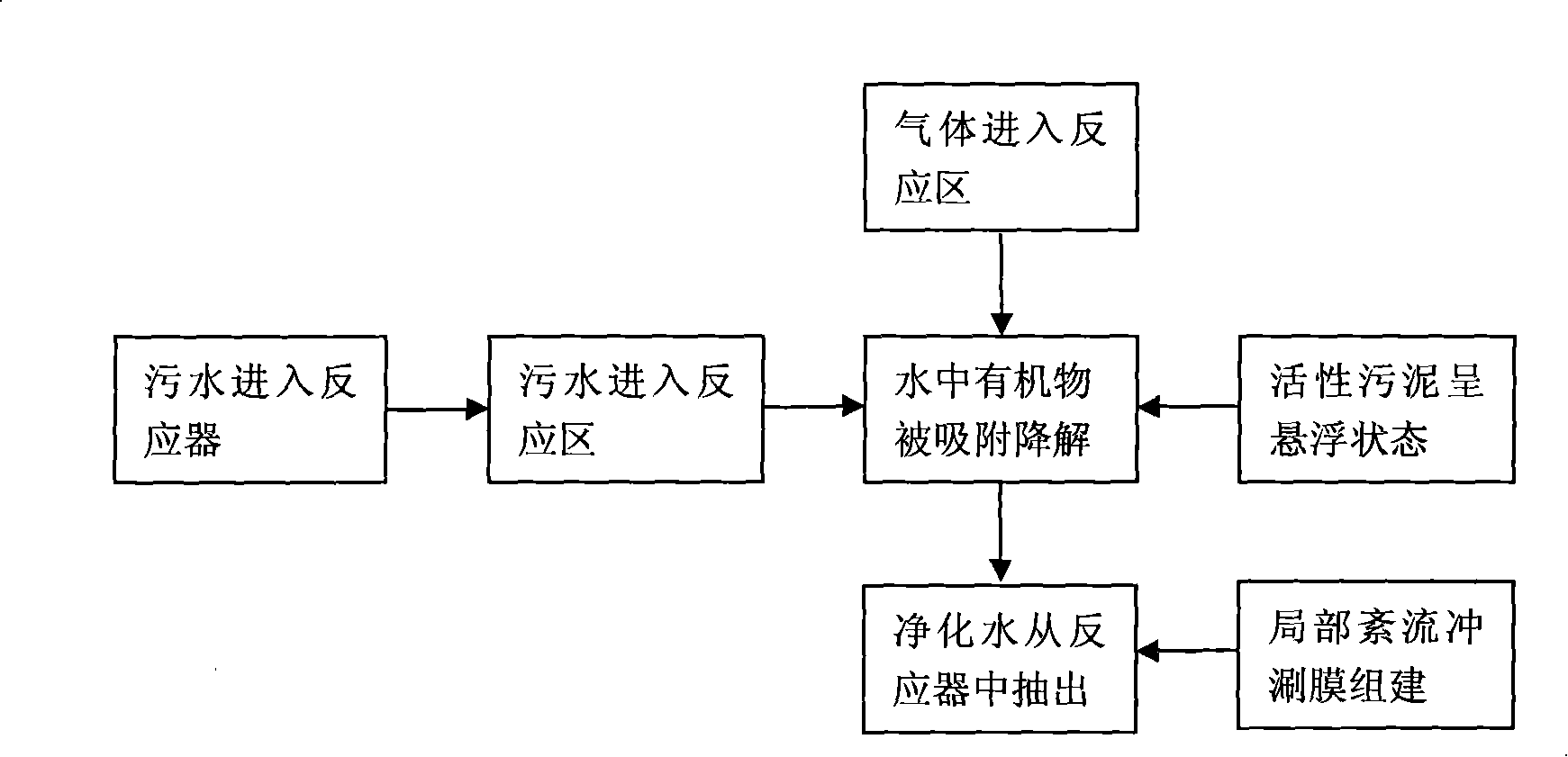

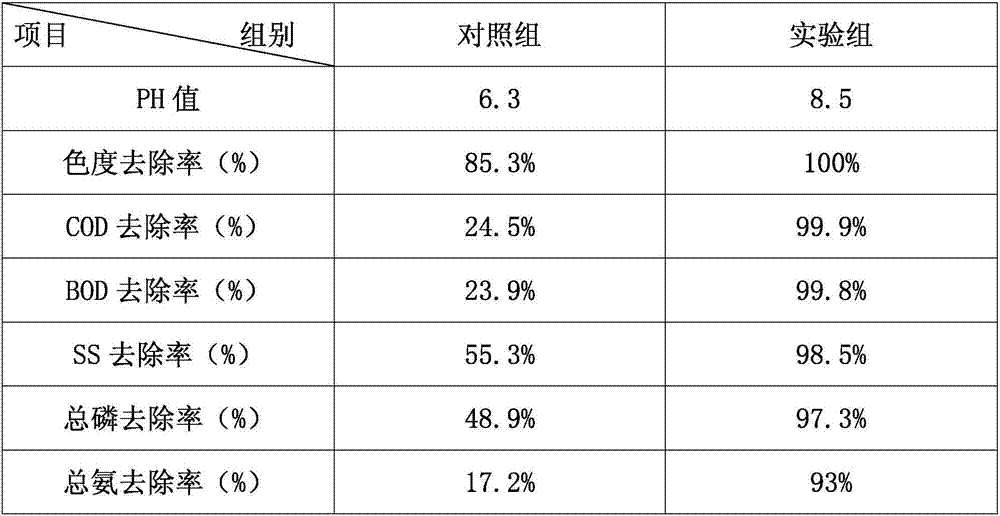

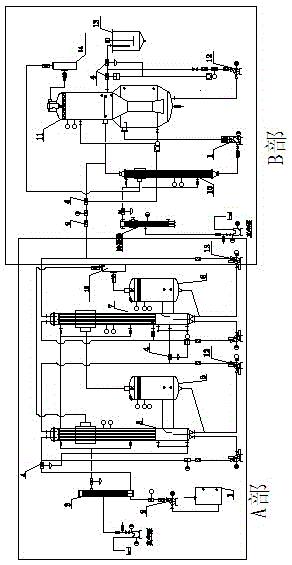

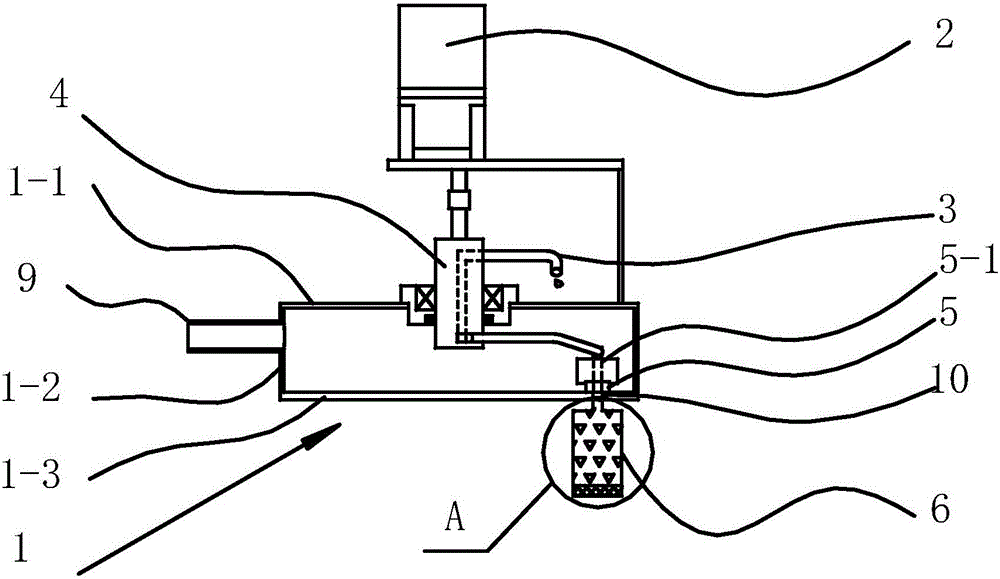

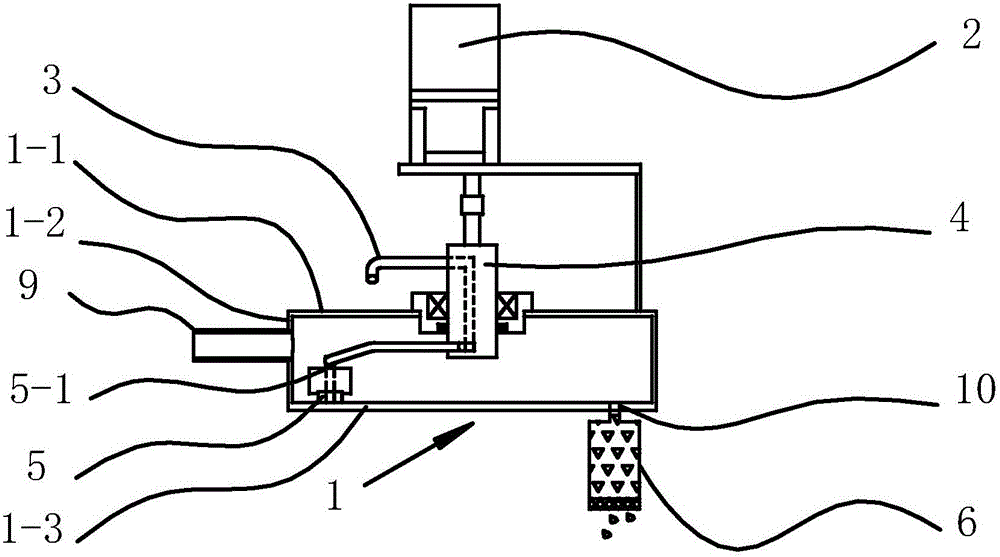

Combination treatment method for combined HMBR and device

InactiveCN101289249AReduce wasteReduce aerator headSustainable biological treatmentBiological water/sewage treatmentPeristaltic pumpReaction zone

The invention relates to a composite HMBR combine processing method and a device thereof. The method includes that sewage enters a reactor by a water inlet pipe (1) and then enters a reaction zone by the bottom of a water inlet clapboard (2-A); gas enters an aerobic reaction zone to react by a pneumatic pump (3) under the control of a gas flow meter (4) from an aeration head (5); the sewage then completely contacts with active sludge (6) in a pool and the sludge attached to semi-soft fillings (7), and organisms in the water are absorbed and degraded. The mixed solution of sludge and water generates local turbulent flow by a right clapboard (2-B) and a deflector (8) having an angle of 45 degrees with the bottom of the pool to wash a membrane component (9) circularly in the pool; the purified sewage is pumped from the reactor by the membrane component (9) by utilizing a peristaltic pump under the control of a liquid flowmeter (11), and meanwhile the water is treated deeply. By adopting the guide flow of the clapboard (2-B) and a deflector (8) lead the water to generate the turbulent flow in the local zone to continuously wash the membrane component (9), the method of the invention spares an aeration head used for washing the membrane component in the traditional composite HMBR and effectively reduces the operating cost without changing the removal efficiency and realizes the 'energy conservation and emission reduction'.

Owner:DONGHUA UNIV

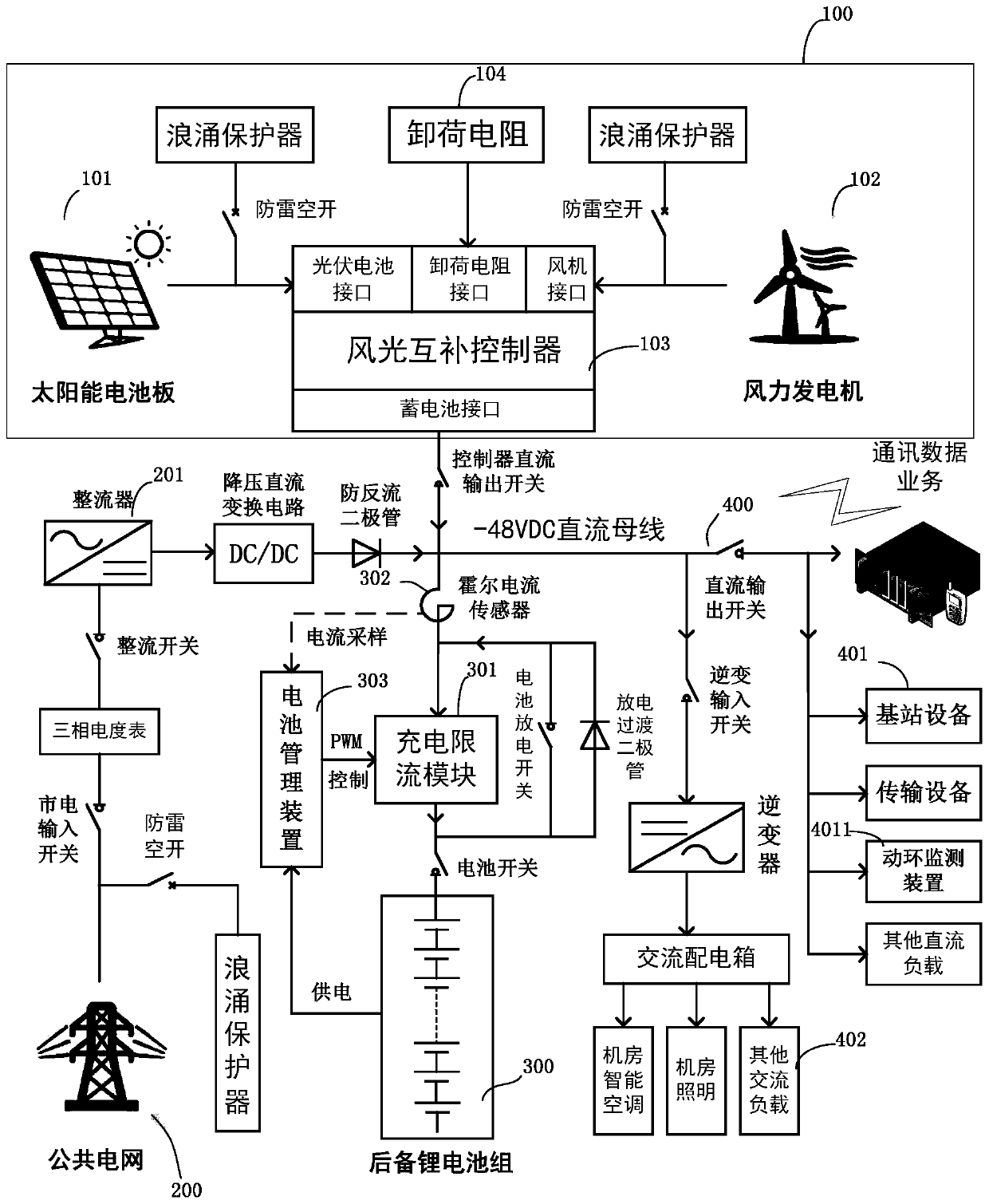

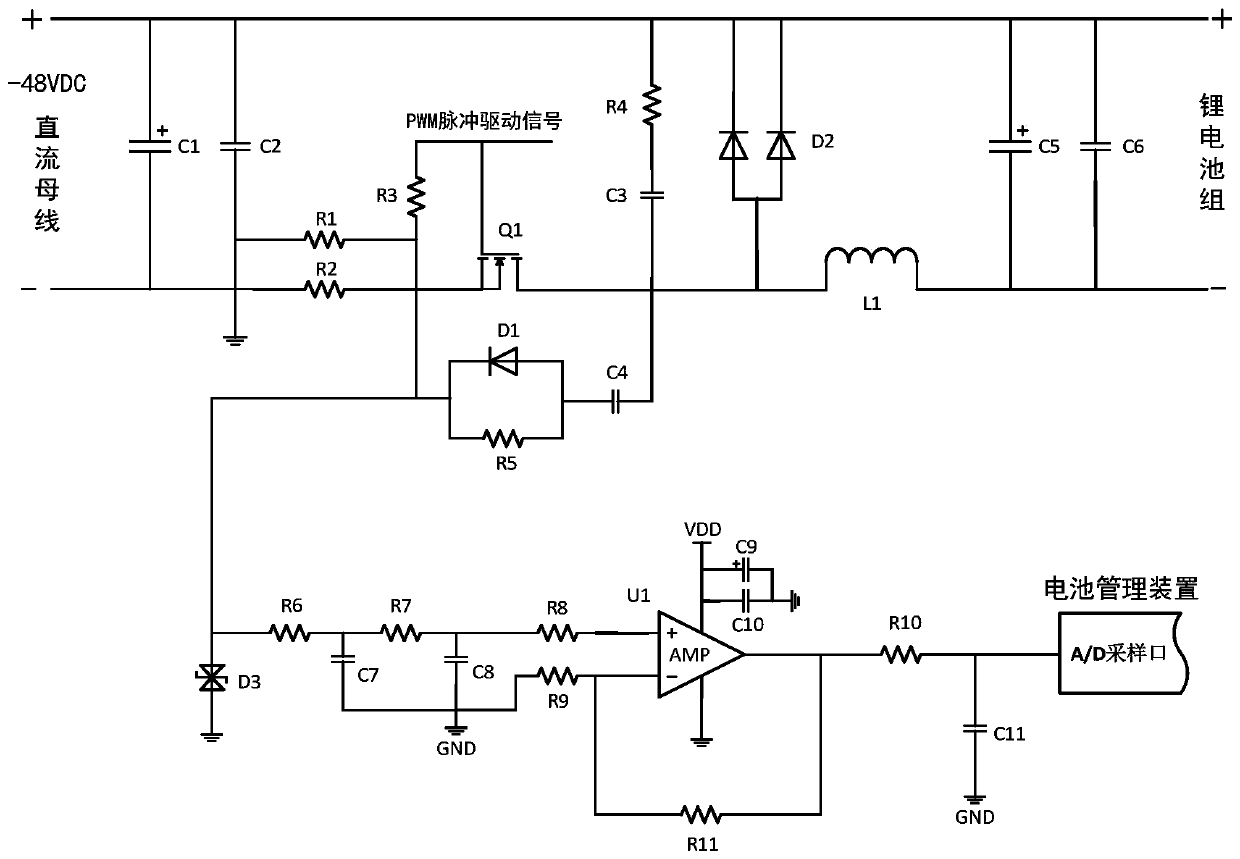

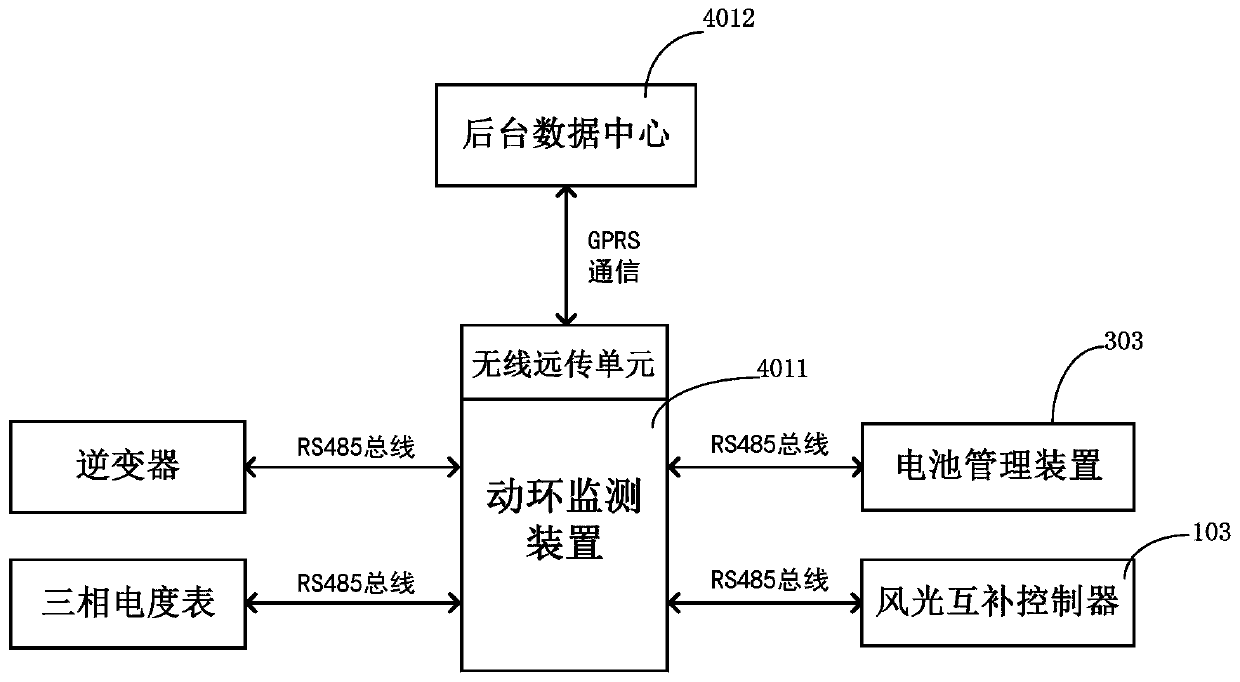

Wind-solar-electricity storage communication base station standby power supply system capable of achieving energy saving and consumption reduction

PendingCN110635559AImprove continuityReduce consumptionPower network operation systems integrationPV power plantsCharge currentThree-phase

The invention relates to the new energy technology field and discloses a wind-solar-electricity storage communication base station standby power supply system capable of achieving energy saving and consumption reduction. The system comprises a solar cell panel, a wind driven generator, a wind-solar complementary controller, a public power grid and a backup lithium battery pack. The solar cell panel and the wind driven generator are electrically connected with the wind-solar complementary controller. The wind-solar complementary controller is electrically connected to a -48VDC direct current bus. The public power grid is electrically connected with a three-phase watt hour meter through a commercial power input switch, is electrically connected to a rectifier through a rectifier switch, andis output to the -48VDC direct current bus through an anti-reflux diode. The backup lithium battery pack is electrically connected to a charging current limiting module through a battery switch, the charging current limiting module is electrically connected with a Hall current sensor, and the Hall current sensor is electrically connected with the -48VDC direct current bus. In the technical scheme,solar energy, wind energy and an energy storage battery can be effectively used for interactive power supply, a energy utilization rate of the base station is increased, and electric energy consumption is greatly reduced.

Owner:深圳市誉娇诚科技有限公司

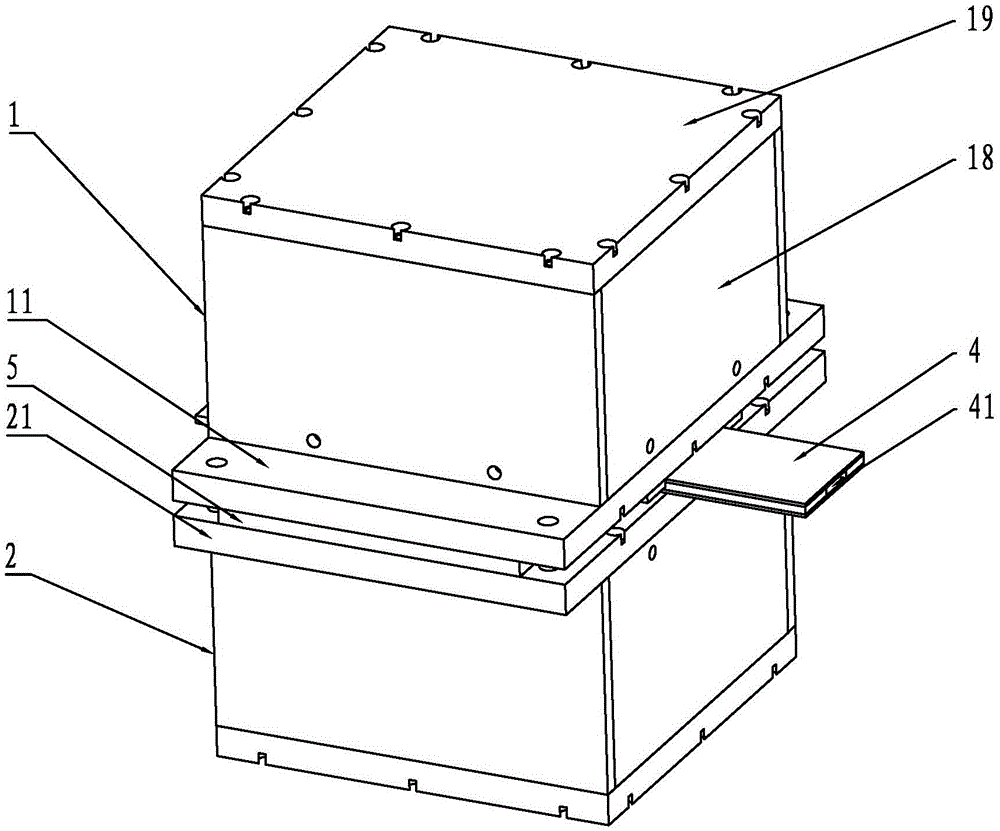

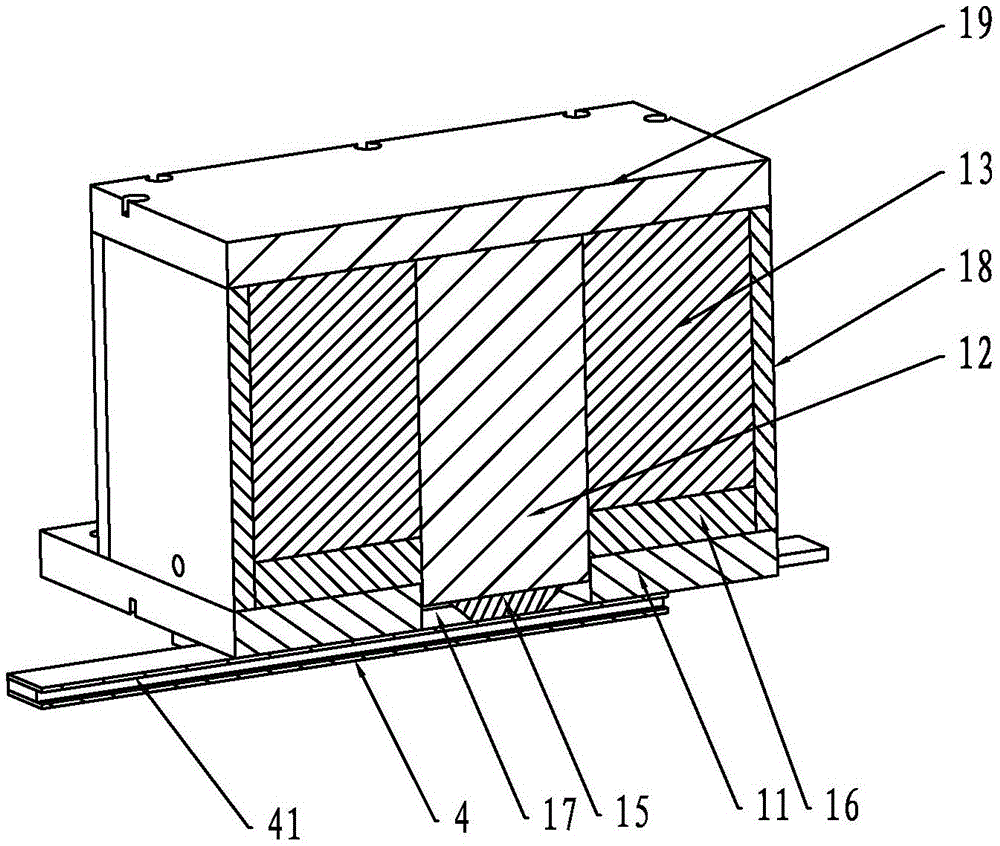

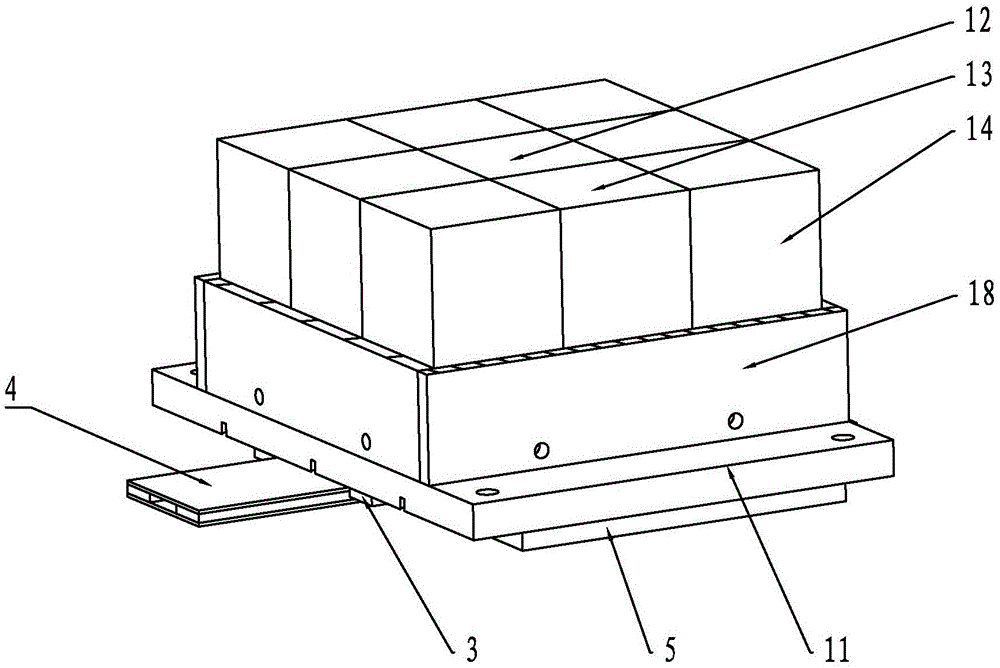

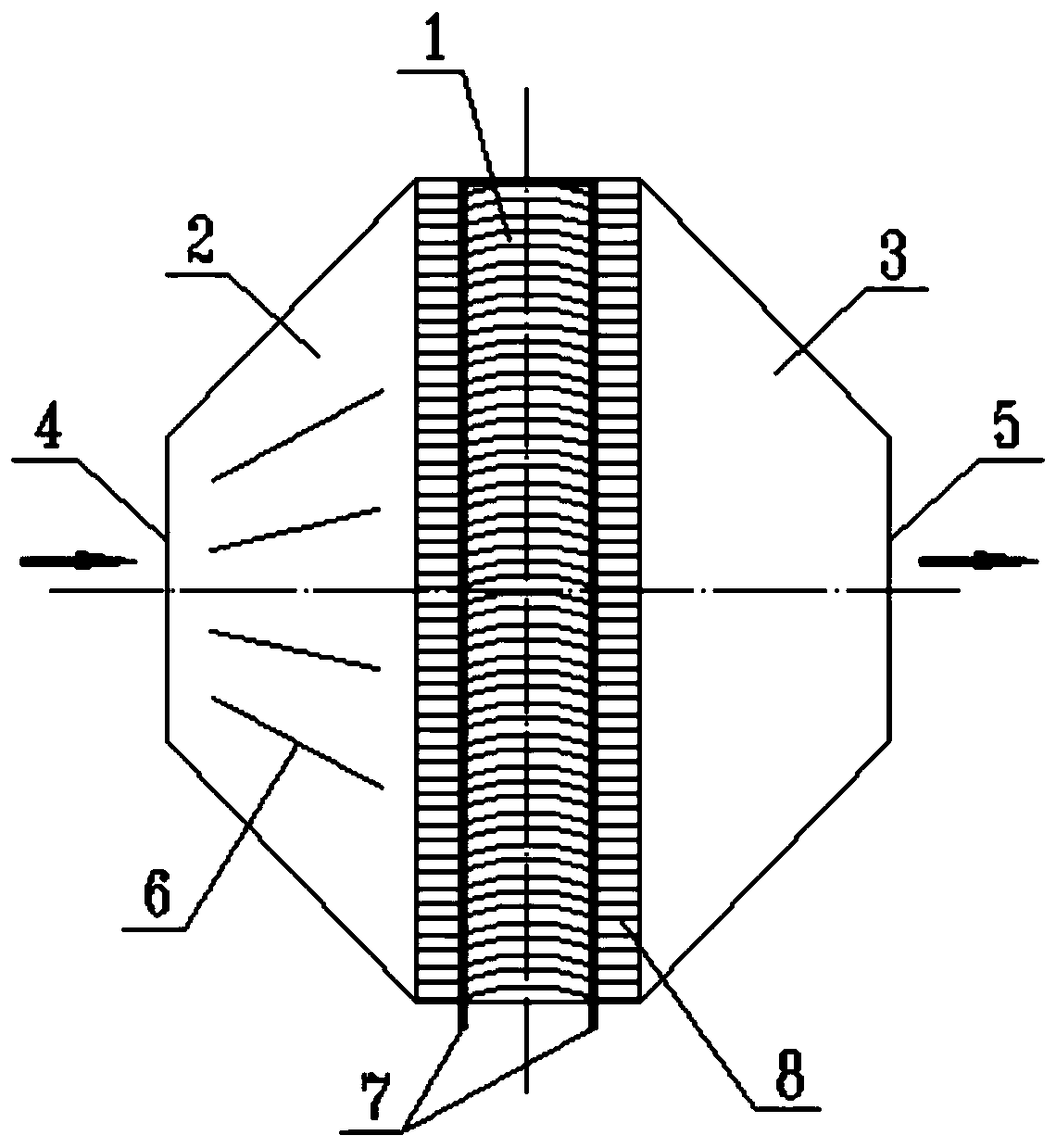

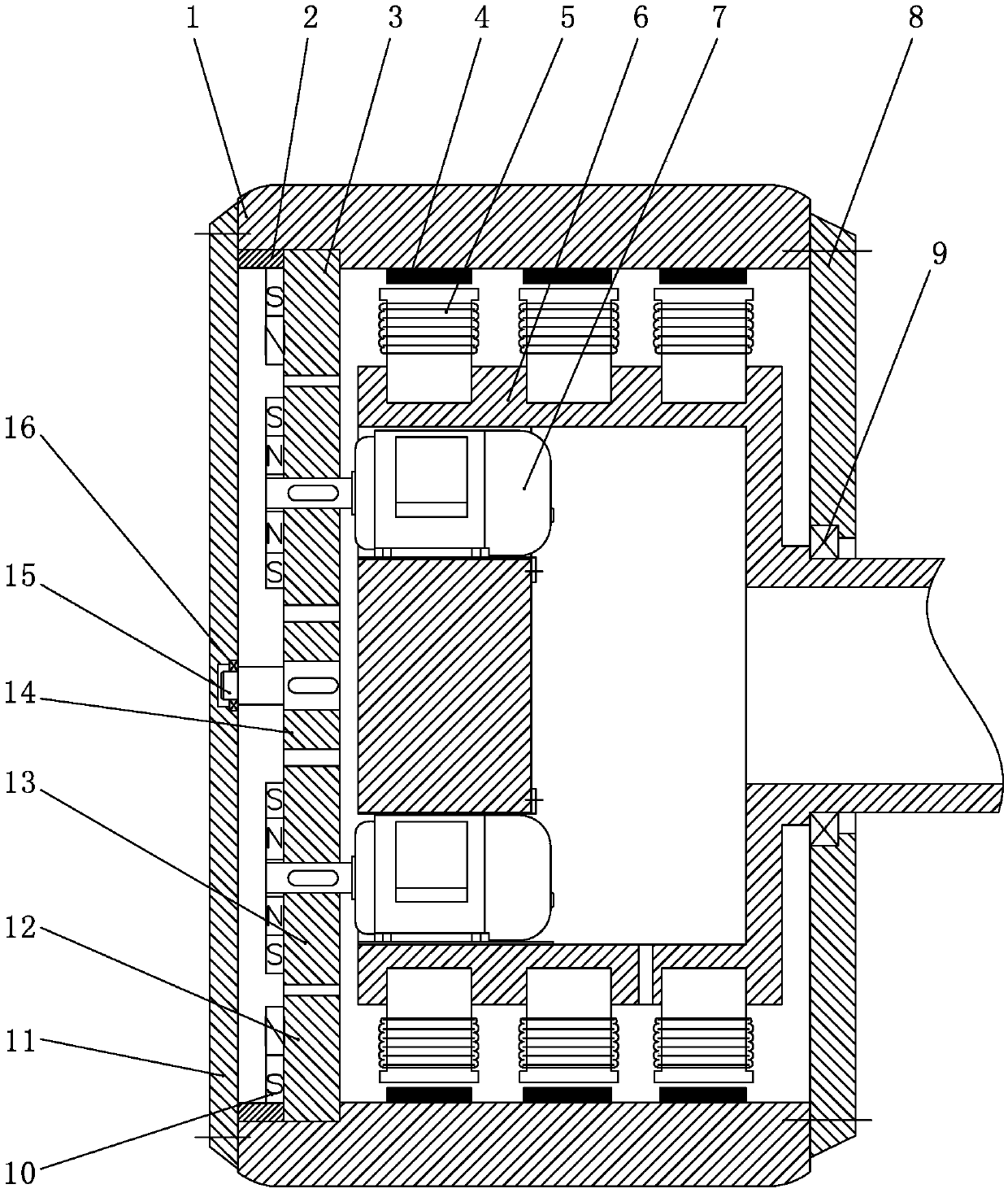

Magnetostatic field magnetizing device and method at normal temperature

ActiveCN105161251AImprove magnetization efficiencyReduce energy consumptionMagnetic bodiesConveyor partsEngineeringMagnetostatics

Owner:天津博雅全鑫磁电科技有限公司

A method for producing cement clinker with unlimited compatibility with carbide slag and limestone as raw materials

ActiveCN102260052ARealize resource utilizationSolve the problem of stacking and polluting the environmentClinker productionCalcium in biologySlag

The invention relates to an unlimited compatible method for producing cement clinker by using carbide slag and limestone as raw materials, belonging to the technical field of resources and environment. The method uses the carbide slag as the calcareous raw materials, and the cement clinker is calcined by using a novel dry technology, which is characterized in that: either 100 percent of carbide slag or 100 percent of limestone can be used as the calcareous raw materials, or the carbide slag and the limestone can be mixed at any ratio for use. A main process comprises the following steps of: (1) kiln rear feeding, in which a preheater can be switched between the stage 3 and the stage 5 through changing a position of a material feeding point; (2) raw material pre-decomposition, in which a five-stage preheater which is switchable to a three-stage preheater and an enhanced suspension spray type decomposition furnace are used in order to combust the fuels and decompose the raw materials, wherein the outlet temperature of the decomposition furnace is controlled between 700 and 890 DEG C; and (3) rotary kiln calcining, in which the decomposed raw materials enter the kiln to be calcined into the cement clinker. The method has the characteristics of high resource regeneration level of the carbide slag, obvious energy-saving and emission-reduction effect, strong system compatibility andthe like.

Owner:成都建筑材料工业设计研究院有限公司

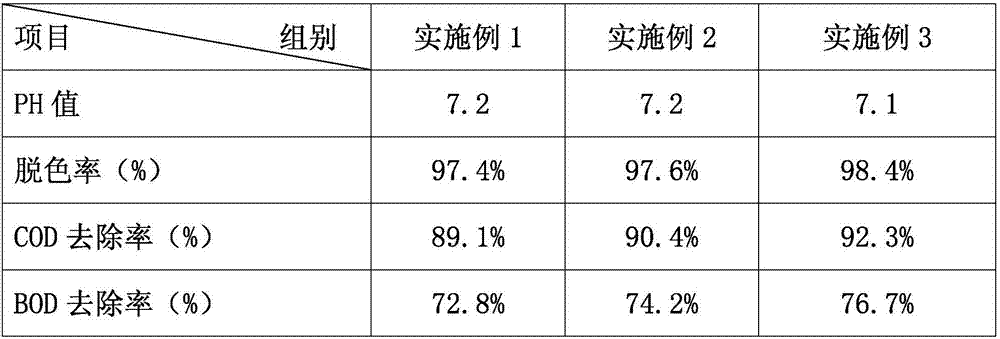

Method for treating printing and dyeing wastewater

InactiveCN106986500AImprove recycling ratesRealize the goal of energy saving and emission reductionTreatment involving filtrationTreatment with anaerobic digestion processesActivated carbonAnaerobic treatment

The invention discloses a processing method for printing and dyeing wastewater, which comprises the following steps: intercepting suspended solids in the printing and dyeing wastewater through a grid machine and a screen; The pond stays for 2 hours for sand settling treatment, and then the wastewater is introduced into the flocculation tank to add flocculant for flocculation treatment. Carry out microbial treatment of wastewater, and then introduce the microbially treated wastewater into the regulating tank, add sodium chlorate and sodium hydroxide to the wastewater, decolorize it and adjust the pH value to make the wastewater clear, and then add activated carbon for deep purification. The clean water is tested for water quality, and then recycled and reused after passing the inspection; the printing and dyeing wastewater treatment method has the characteristics of simple process, convenient operation, low operating cost, good treatment effect and high recycling rate.

Owner:李聪

Device and method for evaporation and crystallization of sodium gluconate solution

ActiveCN105056565AIncrease enthalpyReduce consumptionChemical industryEvaporationEvaporationHeat losses

The invention belongs to the technical field of thermal crystallization for evaporation of a sodium gluconate solution, and particularly relates to a device and a method for evaporation and crystallization of the sodium gluconate solution. A system for recompressing and utilizing secondary steam produced through evaporation is adopted, the secondary steam produced by an evaporation system is compressed and heated by an energy-efficient steam compressor, the enthalpy value of the secondary steam is increased, the secondary steam with the enthalpy value increased enters the evaporation system to be used as a heat source to be recycled, most live steam is replaced, and the live steam is only used for replenishing the heat loss and replenishing the enthalpy required by the incoming and outgoing material temperature difference, so that the live steam consumption of evaporators is substantially reduced, and energy is saved.

Owner:山东凯翔生物科技股份有限公司

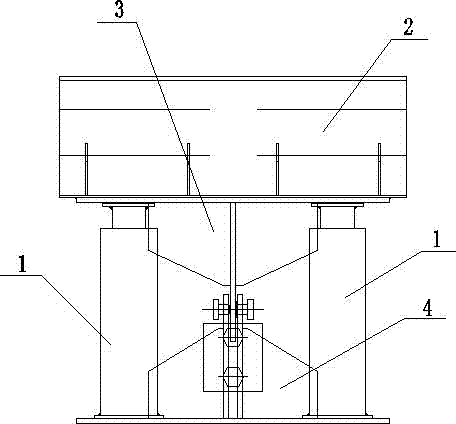

Combined spring support device

InactiveCN103047483AReduce horizontal frictionEliminate vibrationPipe supportsLow frictionStructural engineering

A combined spring support device comprises two spring supports, a vertical pipe bending head support, an upper rigid body and a lower rigid body. The lower rigid body comprises a lower base plate and two lower vertical plates vertically arranged on the lower base plate, the two spring supports are symmetrically distributed on two sides of the lower rigid body, the spring supports are also arranged on the lower base plate, the upper rigid body comprises an upper supporting plate and an upper vertical plate arranged on the upper supporting plate, two ends of the upper supporting plate is pressed on a loading board of the spring supports, upper friction pairs are arranged on a contacting surface of the loading board and the upper supporting plate, and the upper vertical plate stretches into a gap between` the two lower vertical plates in the lower rigid body. The combined spring support device is novel in structure, not only meets the requirement of a vertical thermal displacement support of an inlet and an outlet pipe of a turbo machine, but also solves the problem of axial thermal displacement of horizontal pipes in a very low friction coefficient, thereby greatly reducing the horizontal friction force undertaken by the turbo machine, and simultaneously eliminating the vibration produced during tanscritical speeds and ensuring stable and reliable running of the turbo machine.

Owner:LUOYANG CHANGTIAN TECH

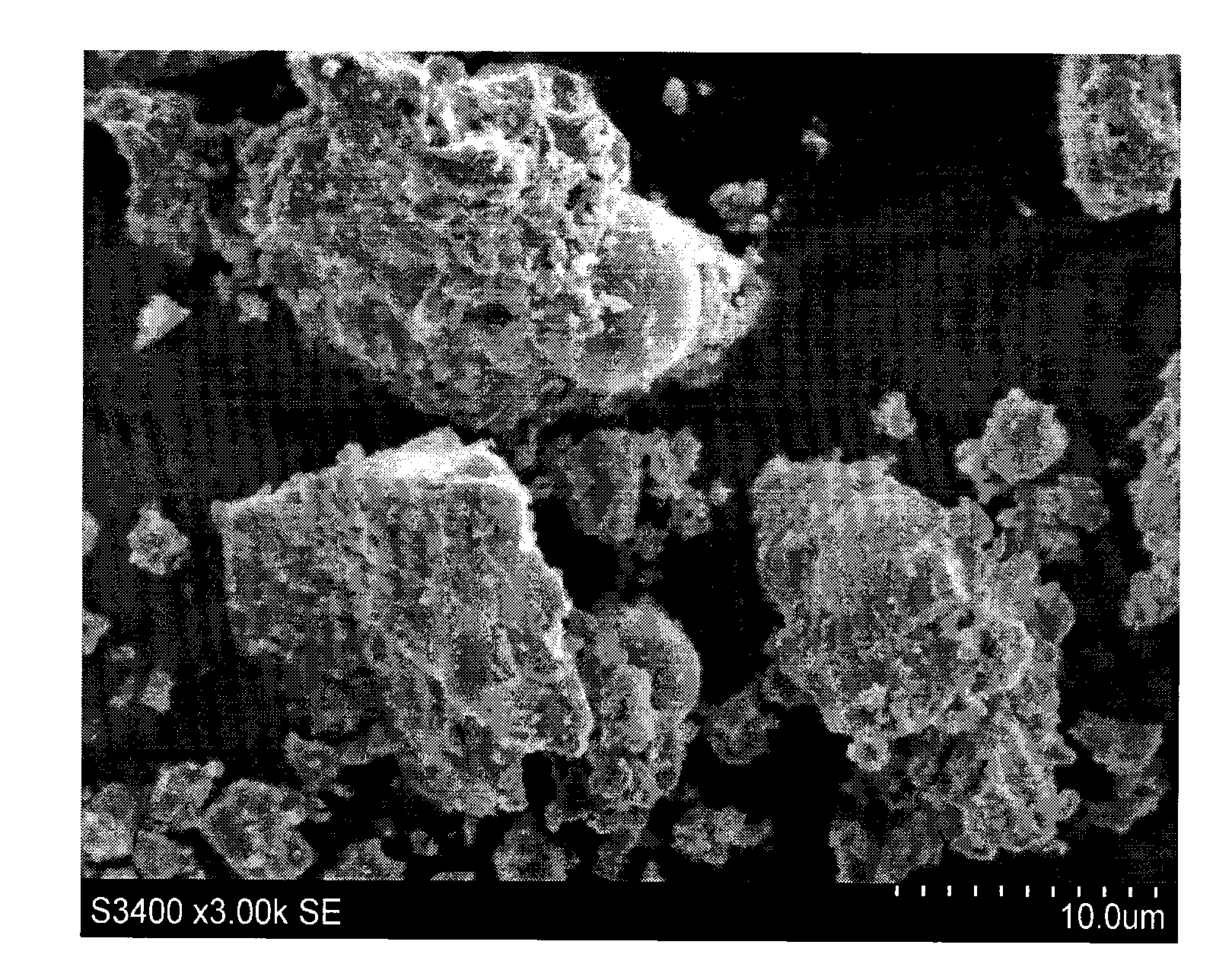

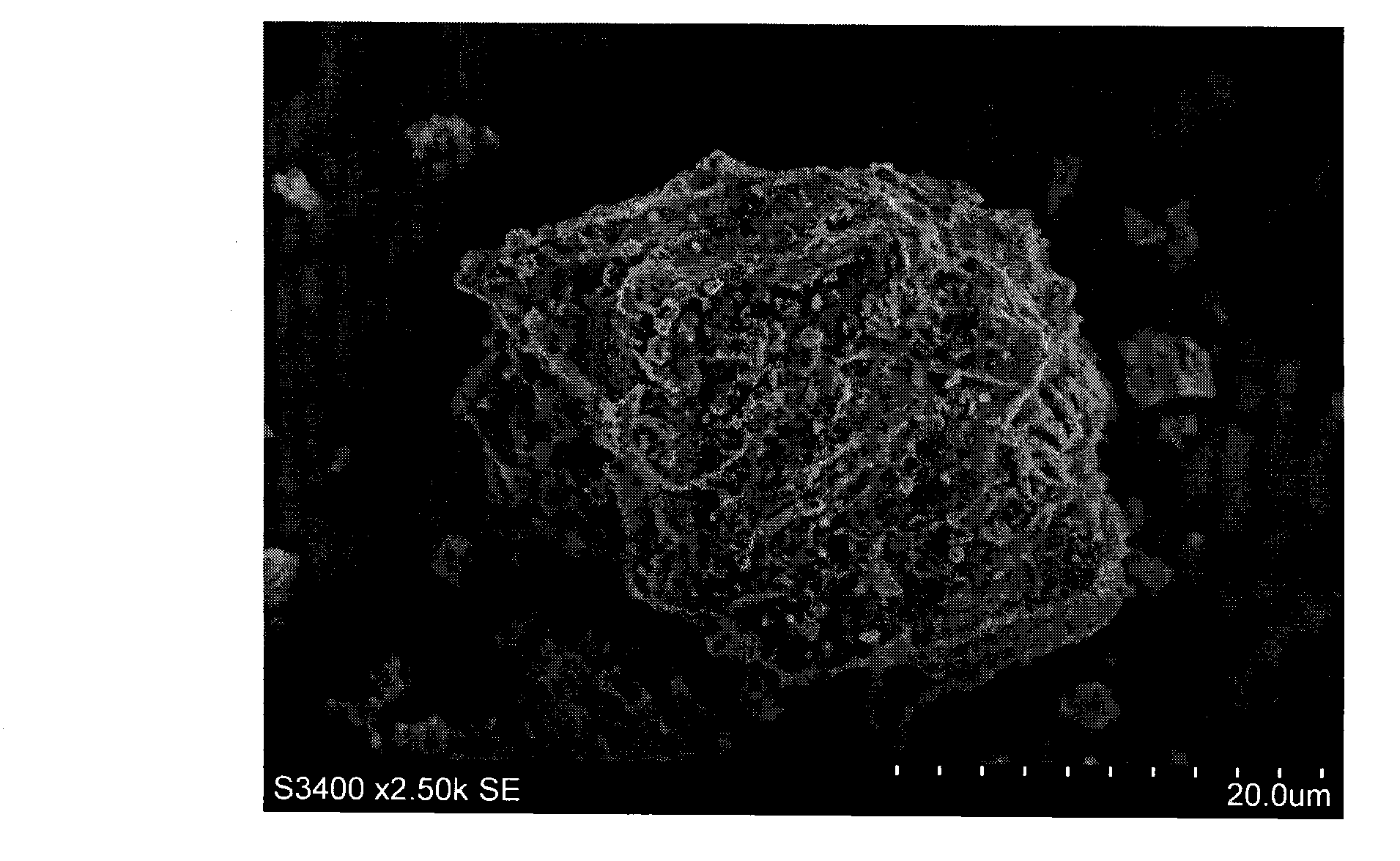

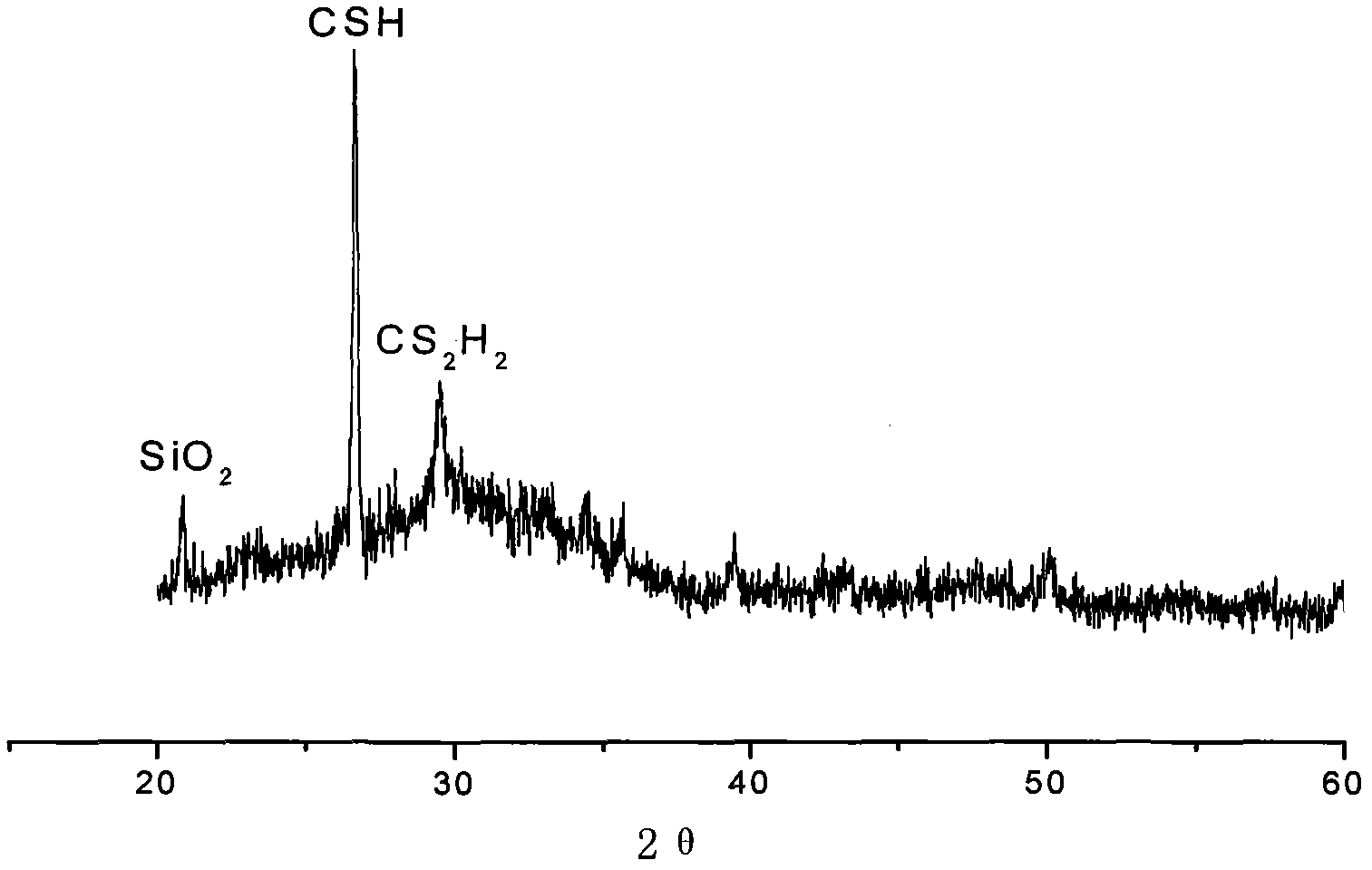

Slag-coal ash compound solid exciter and preparation method thereof

The invention relates to a slag-coal ash compound solid exciter and a preparation method thereof, and belongs to the field of cement and concrete building materials. The preparation method for the slag-coal ash compound solid exciter comprises the steps as follows: carrying out compound modification on sodium hydroxide, sodium carbonate and low-modulus liquid water glass as well as a modifying agent-polyacrylamide or polyphosphate, ageing and digesting in vacuum condition, drying and grinding. The slag-coal ash compound solid exciter overcomes the defects of poor stability of the traditional solid base exciter and difficult field construction of the traditional liquid exciter, has the advantages of good stability, unsuitability for moisture absorption or air slaking and a wide range of material sources, and can be directly mixed and ground with the slag and the coal ash to prepare high-strength hydraulic cementing materials. The cement can be fully replaced with the cementing material obtained by the excitation of the exciter in the concrete, so that the concrete strength can be enhanced by about 20-30%, and the concrete durability can be improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

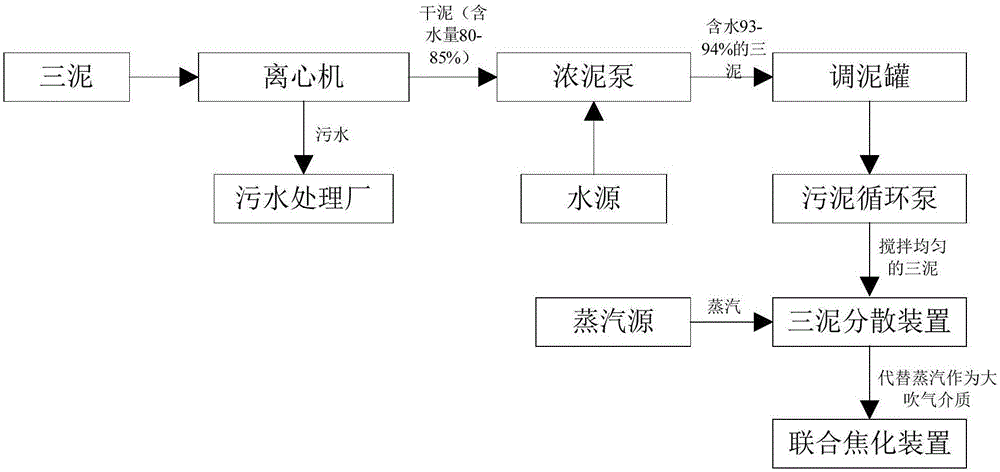

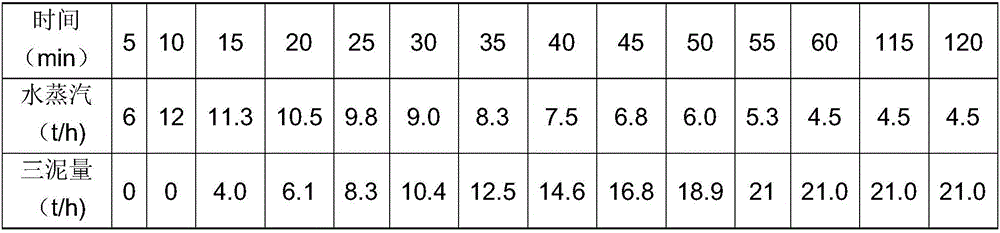

A set of three-sludge recycling treatment technology

ActiveCN106348553AReduce processing difficultyRaise the liquid levelCoke quenchingWater treatment parameter controlWater vaporSludge

The invention provides a set of three-sludge recycling treatment technology which comprises the following steps: adding three sludge and a flocculating agent into a centrifuge for centrifugation; conveying the obtained dry sludge into a thick sludge pump, and conveying the obtained sewage into a sewage treatment plant for recycling treatment; injecting a water flow into the thick sludge pump so as to convert the dry sludge into three sludge with the water content of 93-94%; conveying the three sludge with the water content of 93-94% into a sludge mixing tank, and then conveying the three sludge into a sludge circulating pump from the sludge mixing tank; outputting the uniformly stirred three sludge by the sludge circulating pump; conveying the uniformly stirred three sludge and water vapor together into a three-sludge dispersion device so as to tear and disperse the uniformly stirred three sludge into tiny droplets; and conveying the tiny droplets as a large vapor blowing medium into a joint coking device to finish a coking process. The technology provided by the invention has the following beneficial effects: tiny droplets are obtained through centrifugation, stirring and dispersion, and the droplets can serve as a large vapor blowing medium and enter the joint coking device for recycling; and through the design, all three sludge can be recycled at low cost, and the aims of energy conservation and emission reduction are achieved.

Owner:天津莱特化工有限公司

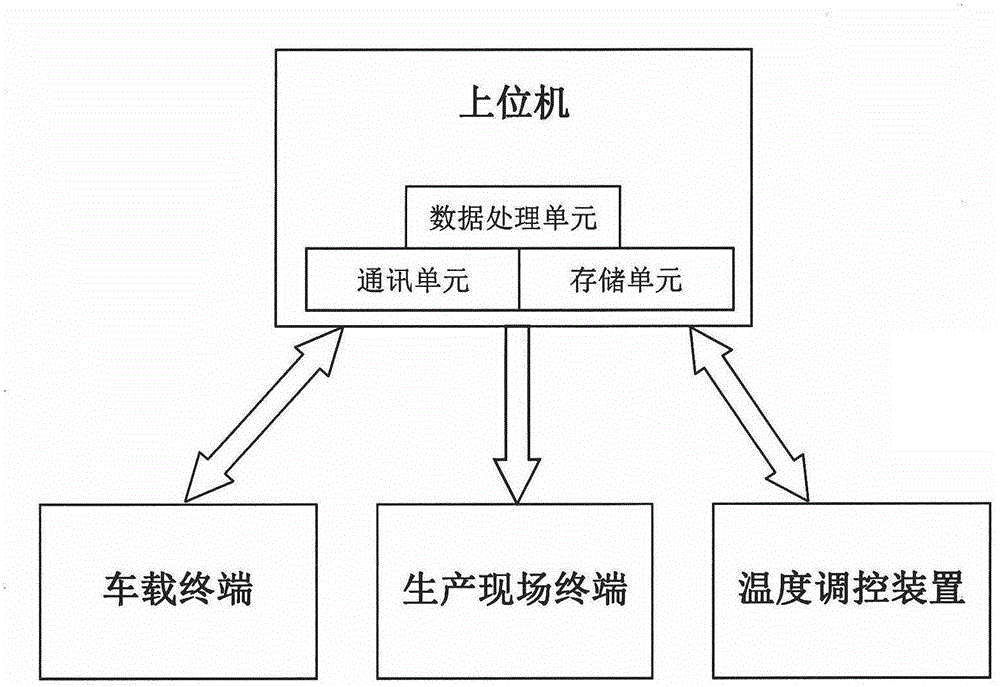

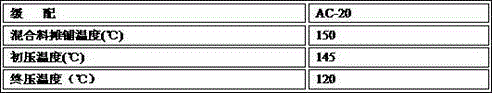

System and method for regulating production temperature of asphalt mixture

ActiveCN104965540ARealize the goal of energy saving and emission reductionTemperatue controlData transmissionData processing

The present invention relates to a system and a method for regulating production temperature of asphalt mixture. The system for regulating production temperature of asphalt mixture consists of a host computer, a vehicle-mounted terminal, a production on-site terminal and a temperature regulating apparatus; wherein the host computer is a computer with a decision system, the decision system comprises a communication unit used for performing data transmission with the vehicle-mounted terminal, the production on-site terminal, and the temperature regulating apparatus, a data processing unit used for calculating factory temperature of the asphalt mixture, and a storage unit used for storing order information such as destination name, work temperature, tonnage quantity, conveying time and contact person and data obtained by processing of the data processing unit such as factory temperature, environment temperature, road condition information, transport time and transport line. The system of the present invention comprehensively considers factors such as transport road condition, transport environment and construction environment of the asphalt mixture to calculate the lowest factory temperature of the asphalt mixture in advance, so as to control the factory temperature of a product during the production process of the asphalt mixture, thereby achieving energy saving and emission reduction.

Owner:BEIJING POLYTECHNIC

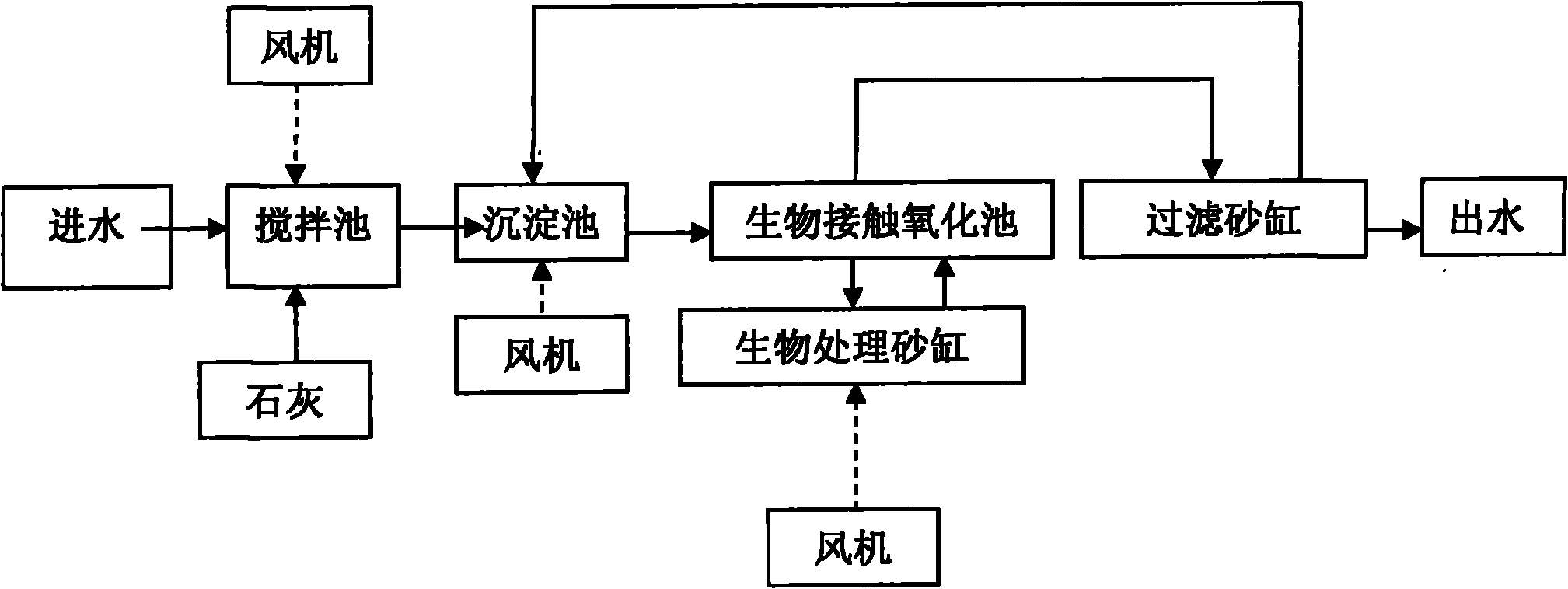

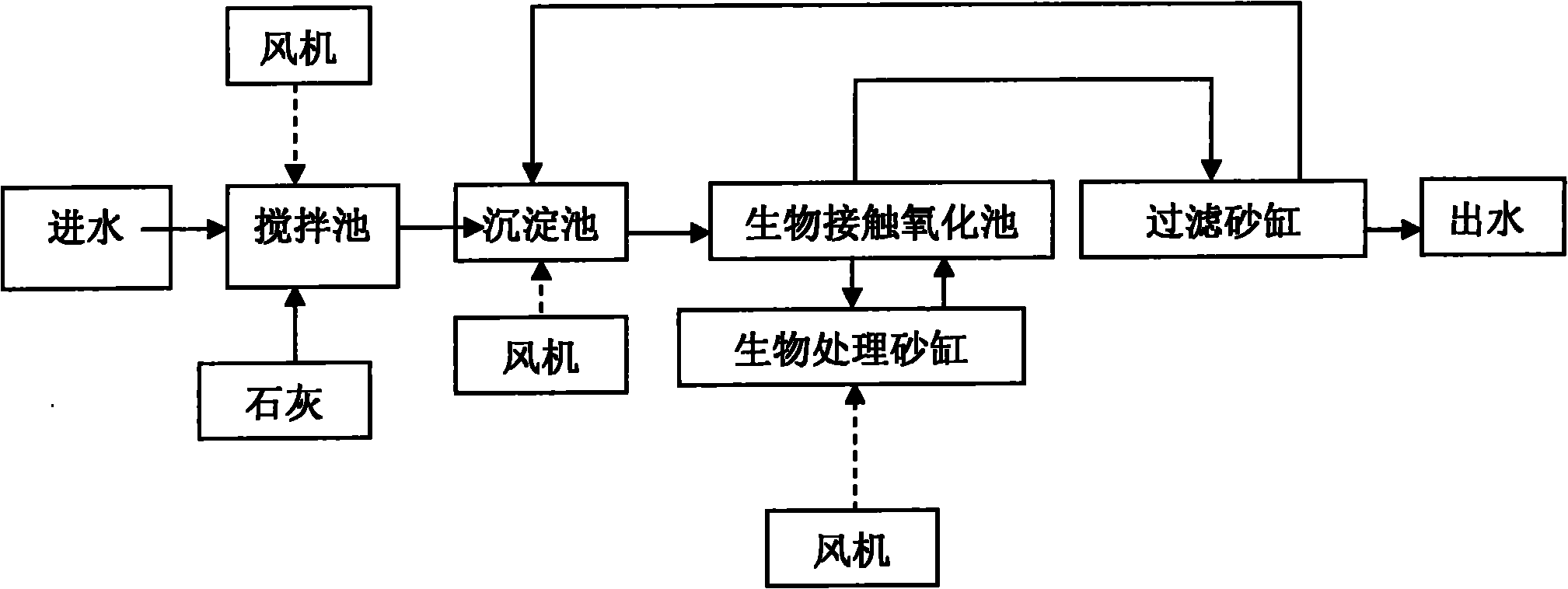

Reclaimed water recycling process

InactiveCN101767900AThe effect is positive and obviousRealize the goal of energy saving and emission reductionMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processPhosphateReclaimed water

The invention relates to a reclaimed water recycling process, which comprises a step of removing phosphorus and a step of removing COD. In the step of removing phosphorus, lime is added into reclaimed water to utilize lime to react with phosphate to deposit. In the step of removing COD, a biological filter material is utilized to decompose organic substances in the reclaimed water, remove the COD in the water, convert nitrogen into nitrate nitrogen from organic nitrogen and then carry out filtering and sterilization. After being processed by the method of the invention, the domestic sewage can reach the primary standard in the city comprehensive discharge standards, can be recycled as the reclaimed water and fulfills the aim of saving energy and reducing emission.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Short-flow preparation method for padder dyed umbrella cover cloth

InactiveCN107964781AReduce dyeing productionEmission reductionFibre treatmentDyeing processColor saturationEnergy consumption

Belonging to the technical field of dyed umbrella cover cloth manufacturing, the invention discloses a short-flow preparation method for a padder dyed umbrella cover cloth. The method includes the steps of: a) umbrella cover cloth pretreatment: soaking an umbrella cover cloth in a strong alkali solution and performing washing to obtain pretreated umbrella cover cloth; b) dyeing liquor preparation:mixing an alkali liquid with a dye solution to obtain dye liquor; c) padding the pretreated umbrella cover cloth in the dye liquor to obtain dyed umbrella cover cloth; d) baking and color fixing: baking the padded umbrella cover cloth to obtain baked umbrella cover cloth; and 3) washing. The method provided by the invention is suitable for all medium color and light color systems, and can reduce50-60% of dye vat dyeing production, and the color accuracy can reach 99% or more. The method provided by the invention can reduce sewage discharge and energy consumption on the basis of guaranteeingthe existing product quality, and achieves the goal of energy saving and emission reduction. The umbrella cover cloth prepared by the method provided by the invention has the characteristics of high color saturation, good color fastness, etc.

Owner:ZHEJIANG SHENGSHAN TECH TEXTILE

Method for preparing granular fuel by utilizing water hyacinth

InactiveCN107488479AQuality improvementReduce pollutionBiofuelsSolid fuelsCompressive resistanceEngineering

The invention provides a method for preparing granular fuel by utilizing water hyacinth. The method comprises a set of scientific reasonable steps of mechanically harvesting, naturally airing, crushing into grains, regulating water content, heating, pressurizing and forming. The preparation method is simple, the operation is easy and the granular fuel is prepared under excellent technical conditions; the grain density and the radial compressive resistance of the granular fuel respectively reach up to 1362.21kg / m3 and 1.44KN; the preparation for high-quality granular fuel not only effectively utilizes the water hyacinth resource and reduces the water hyacinth pollution, but also provides a high-quality clean energy, effectively reduces the combustion of non-renewable fuels, such as coal and oil, and achieves the purpose of 'energy conservation and emission reduction'.

Owner:陈远志

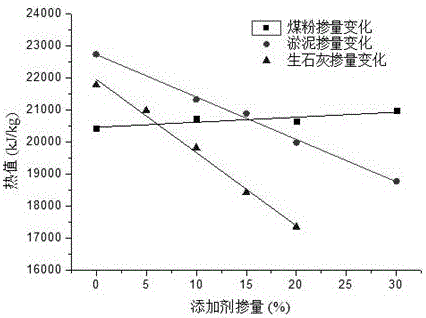

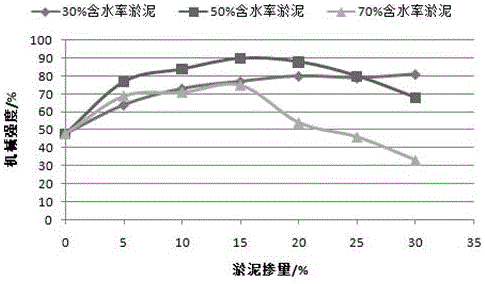

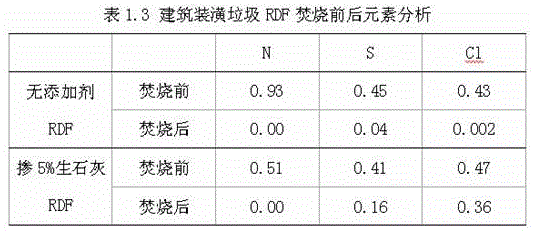

Building decoration waste derived fuel and method for preparing same

InactiveCN106318511AReduce coal useHigh social and environmental benefitsBiofuelsSolid fuelsCoalSilt

The invention discloses building decoration waste derived fuel and a method for preparing the same. The building decoration waste derived fuel comprises, by weight, (50-75) wt% of organic light components, (0-30) wt% of pulverized coal, (0-30) wt% of river silt and (0-20) wt% of quicklime. Building decoration waste is sorted to obtain the organic light components, the organic light components are used as main raw materials for the building decoration waste derived fuel, and the pulverized coal, the river silt and the quicklime are used as additives and are added into the organic light components. The method includes proportionally mixing the organic light components from the building decoration waste, the pulverized coal, the river silt and the quicklime with one another to obtain mixtures; carrying out compression molding and processing on the mixtures to obtain the building decoration waste derived fuel. The building decoration waste derived fuel and the method have the advantages that a heat value of the building decoration waste derived fuel prepared by the aid of the method can reach (20000-25000) kJ / kg, the mechanical strength of the building decoration waste derived fuel can reach 90% at least, a chlorine element consolidation proportion can reach 78% at least, and the building decoration waste derived fuel can be used as environment-friendly regenerated fuel in the pyroelectricity industry to partially replace coal; the building decoration waste and the river silt which are two types of solid waste can be recycled, and a way with high additional values can be provided for utilizing the building decoration waste and the river silt.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Integrated automatic treatment device for removing oil-containing wastewater particles and purifying oil

InactiveCN105797446AEasy to replaceEasy to disassembleWaste water treatment from quariesFatty/oily/floating substances removal devicesAtmospheric airWastewater

The invention relates to an integrated automatic treatment device for removing oil-containing wastewater particles and purifying oil. The device comprises a pressure-bearing tank, a filtering device, a driving device and a backflushing device. The backflushing device comprises a backflushing pipeline, a rotary shaft and a suction cup. The upper portion of the rotary shaft is arranged above an upper sealing plate. The lower portion of the rotary shaft penetrates through the upper sealing plate and extends into the pressure-bearing tank. The driving device is connected with the upper portion of the rotary shaft. The backflushing pipeline extends to the upper portion of the upper sealing plate through the rotary shaft. The suction cup is attached to the inner surface of a lower sealing plate, slides and can be kept sealed. A filtering opening is formed in the sliding track of the suction cup. By means of the treatment device, oil field waste water can be effectively filtered, backflushing is conducted by means of difference between the bottom of a filtering single body and atmospheric pressure, backflushing can be achieved during filtering, and the problems that a traditional method is low in waste water treatment efficiency and continuous work can not be achieved are solved.

Owner:CHANGZHOU UNIV

Turbulent heat transfer efficient heat exchange technology

InactiveCN109798798ARealize turbulent heat transferImprove heat exchange capacityIndirect heat exchangersHeat exchanger casingsSurface layerWave shape

The invention relates to a turbulent heat transfer efficient heat exchange technology. The turbulent heat transfer efficient heat exchange technology comprises the steps that a smoke distributor is arranged in an air inlet tube to control the flow speed and flow direction of smoke entering a heat exchange area, and the uniformity of equipment heat exchanging is enhanced; and an existing flat platetype fin structure is changed to a wave shape structure, fins are changed into a flow pass structure, through the changing of the flow pass structure, the smoke forms a large amount of small-scale vortex in a flow pass during flowing, the vortex forms scouring action for the wall surface, a smoke wall surface layer structure is changed, smoke turbulent heat exchange is realized, the heat exchangeproperty of the smoke is improved, the temperature difference between gas and water is reduced, waste heat recovery is enhanced, the enterprise operation cost is reduced, and an energy-saving targetis better realized.

Owner:贵州省六盘水双元铝业有限责任公司

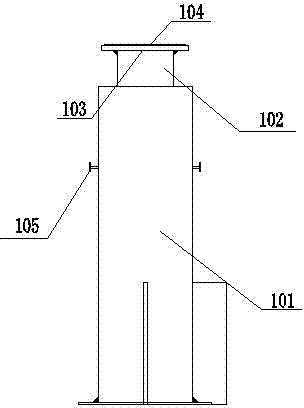

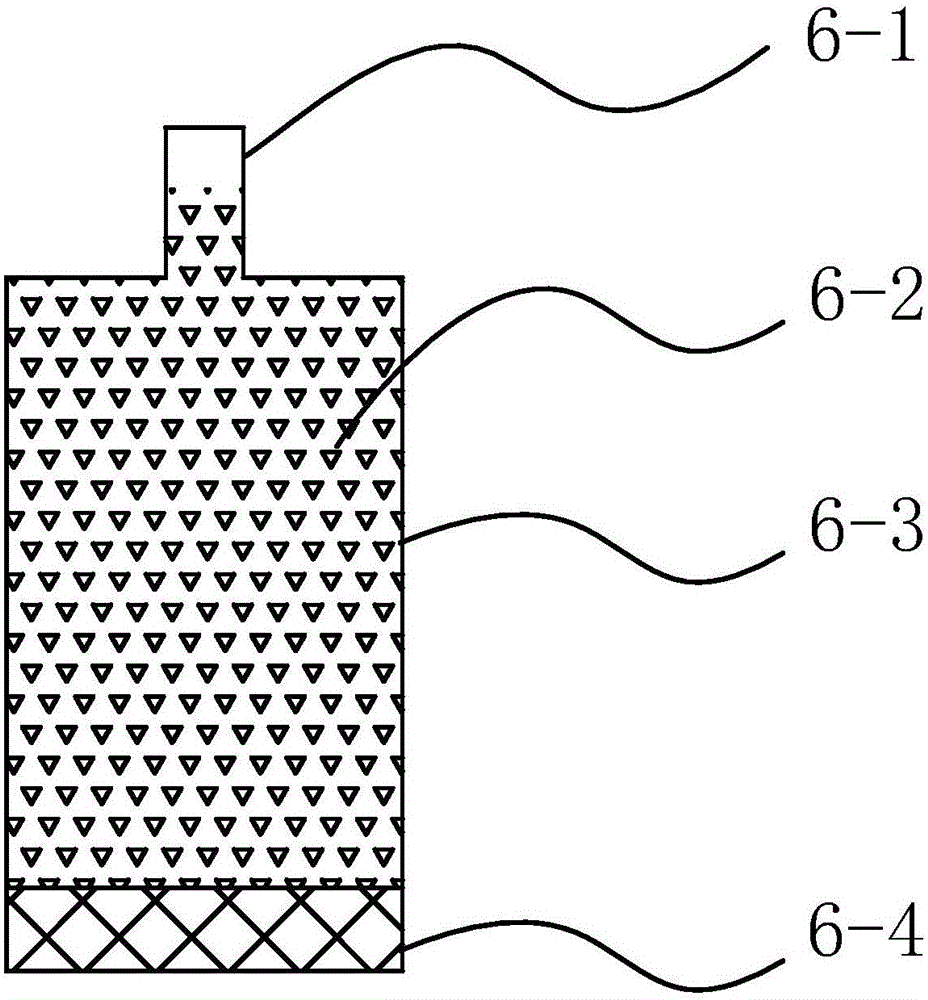

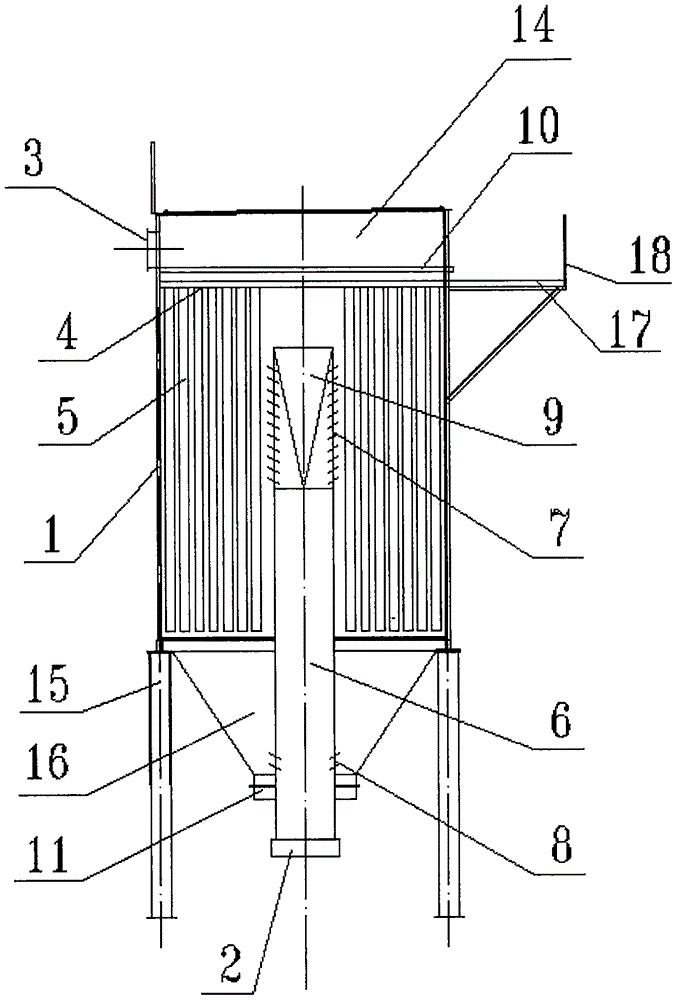

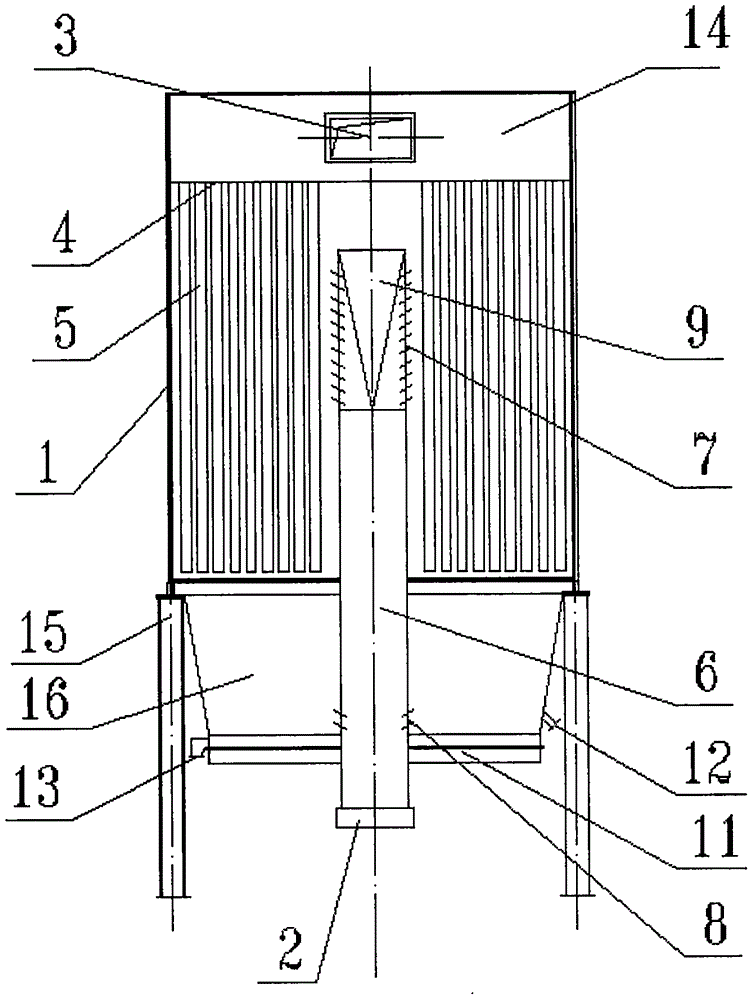

Internal circulation dry-process purification technology and equipment

InactiveCN105964073AEliminate the problem of uneven distribution in the vertical directionThe realization of the problem of uneven distribution in the vertical directionDispersed particle filtrationFluidized bedBaghouse

The invention discloses an internal circulation dry purification technology and equipment, comprising a clean air chamber, a bag filter box, a material collection device and a supporting device, the top of the bag filter box is equipped with a clean air room, and the bottom is installed with a material collection device, support devices are installed around the bottom, the side wall of the clean air chamber is provided with an air outlet, the inside of the bag filter box is provided with a flower plate, a filter device and an internal circulation pipe, and louvers are installed on the top side wall of the internal circulation pipe A tuyere, the side wall of the internal circulation pipe in contact with the material collection device is provided with a circulation material port, a fluidized bed is installed on the outer wall of the internal circulation pipe between the circulation material port and the air inlet, and the side wall of the material collection device A material overflow port is provided, and an emptying port is provided on the bottom side wall of the material collecting device. The invention has good filtering effect, high purification efficiency, compact structure, less space occupation, low investment and operation cost, low operation management and maintenance cost, and can realize the goal of energy saving and emission reduction.

Owner:HUNAN LANZHITIAN ENVIRONMENTAL PROTECTION TECH IND CO LTD

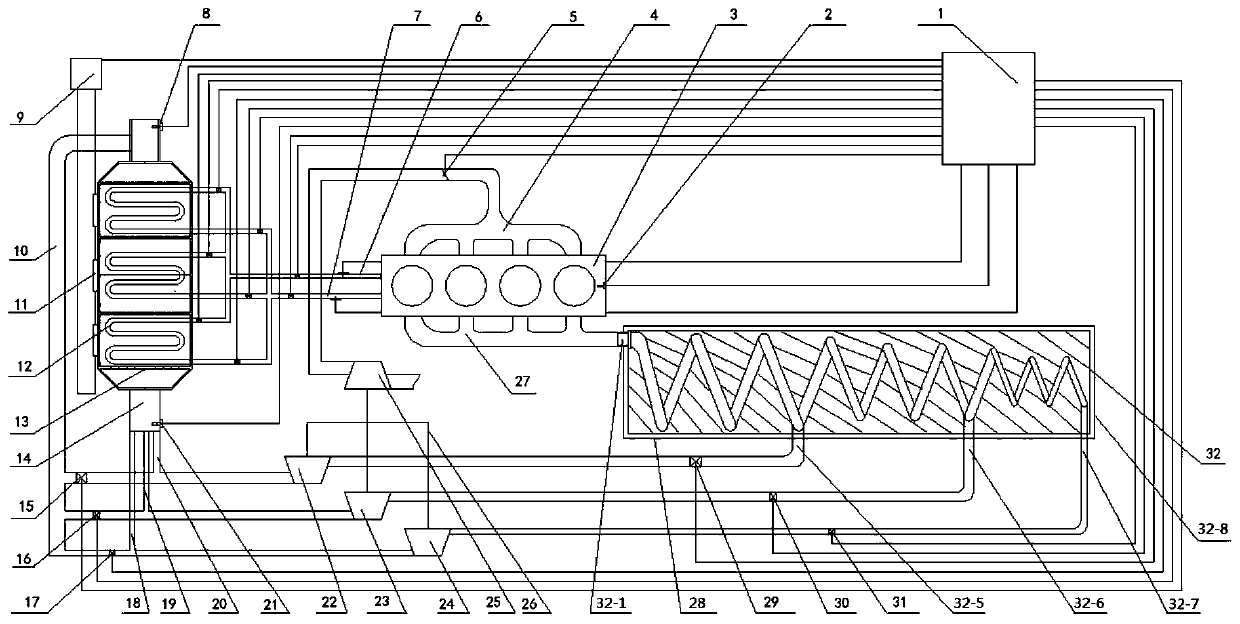

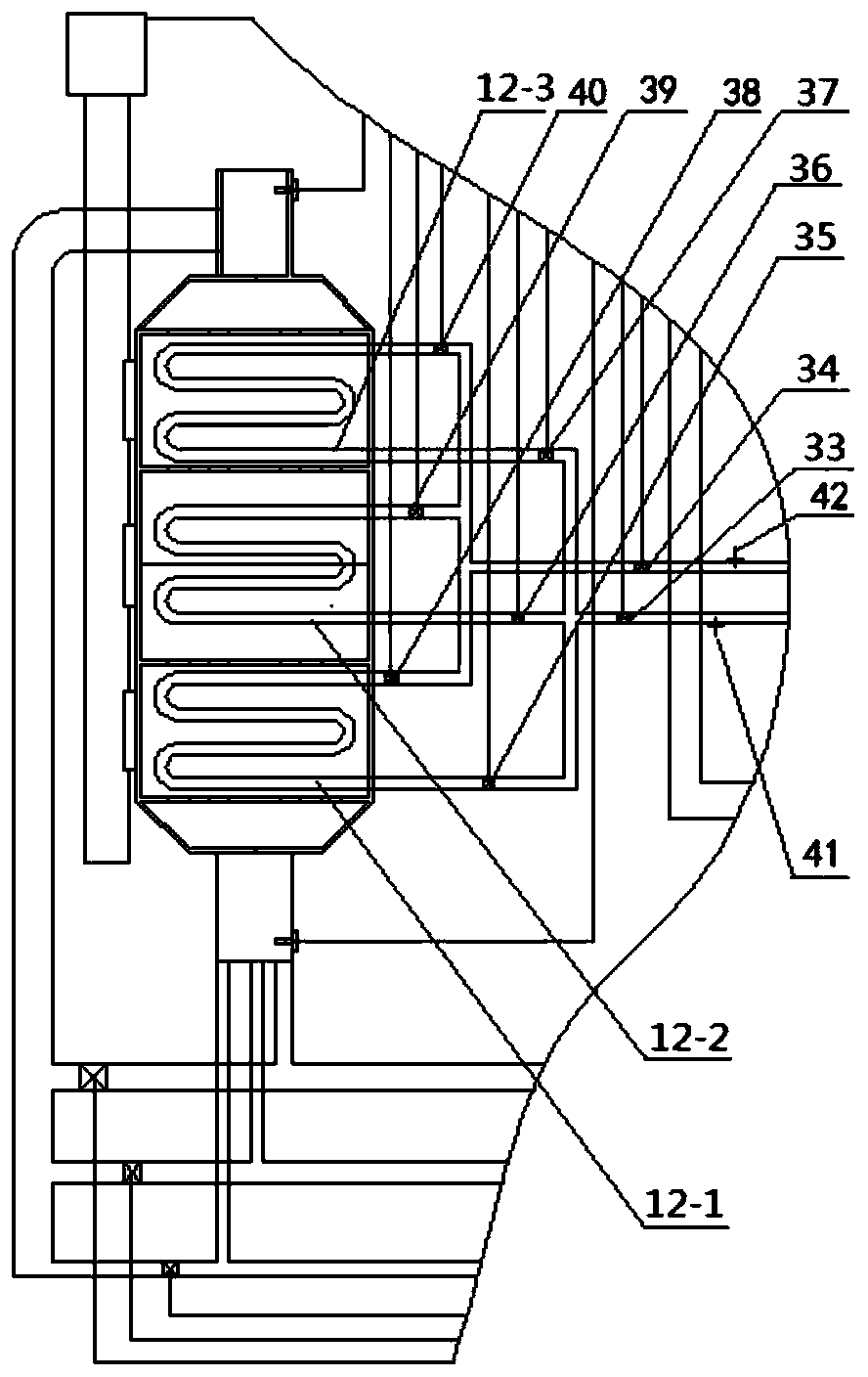

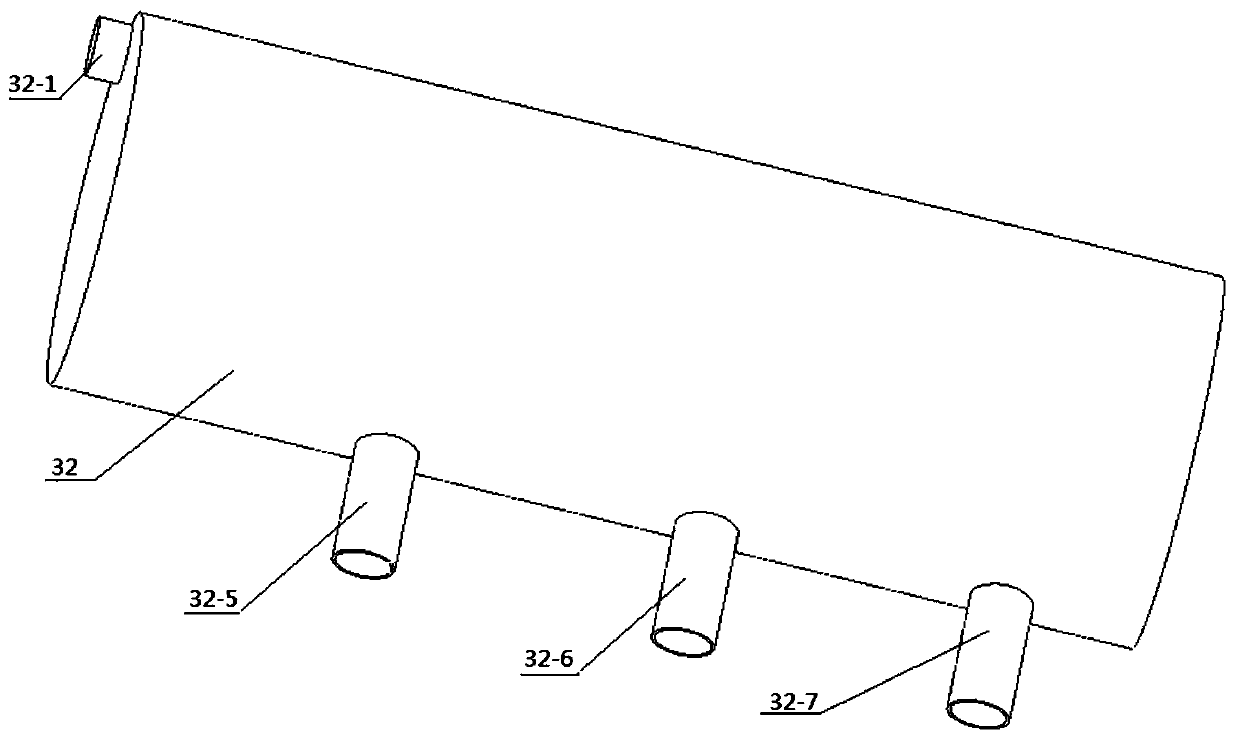

A multi-stage combined recovery device for vehicle engine exhaust energy

ActiveCN108643994BIncrease air densityImprove volumetric efficiencyInternal combustion piston enginesExhaust apparatusElectronic throttleIn vehicle

The invention relates to a multi-stage united recycling device for exhaust energy of a vehicle-mounted engine. The multi-stage united recycling device comprises an electronic control unit, a rotatingspeed sensor, the vehicle-mounted engine, an intake manifold, an electronic throttle valve, a waste heat energy recycling device, an exhaust inlet, a high-speed turbine, a mid-speed turbine, a low-speed turbine, an intake compressor, an exhaust manifold, a high-speed exhaust electromagnetic valve, a mid-speed exhaust electromagnetic valve, a low-speed exhaust electromagnetic valve and a waste kinetic energy and waste pressure energy conversion device, wherein the on-off of the high-speed exhaust electromagnetic valve, the mid-speed exhaust electromagnetic valve and the low-speed exhaust electromagnetic valve is controlled by the electronic control unit, so that the intake compressor is combined with the corresponding started high-speed turbine, mid-speed turbine or low-speed turbine to form a turbo charger used for recycling waste kinetic energy and waste pressure energy in exhaust, the exhaust can be discharged into the waste heat energy recycling device through the high-speed turbine, the mid-speed turbine or the low-speed turbine, and then waste heat energy can be recycled. By adoption of the multi-stage united recycling device provided by the invention, the multi-stage united cascade recycling of energy in the exhaust of the vehicle-mounted engine can be achieved.

Owner:HUNAN UNIV

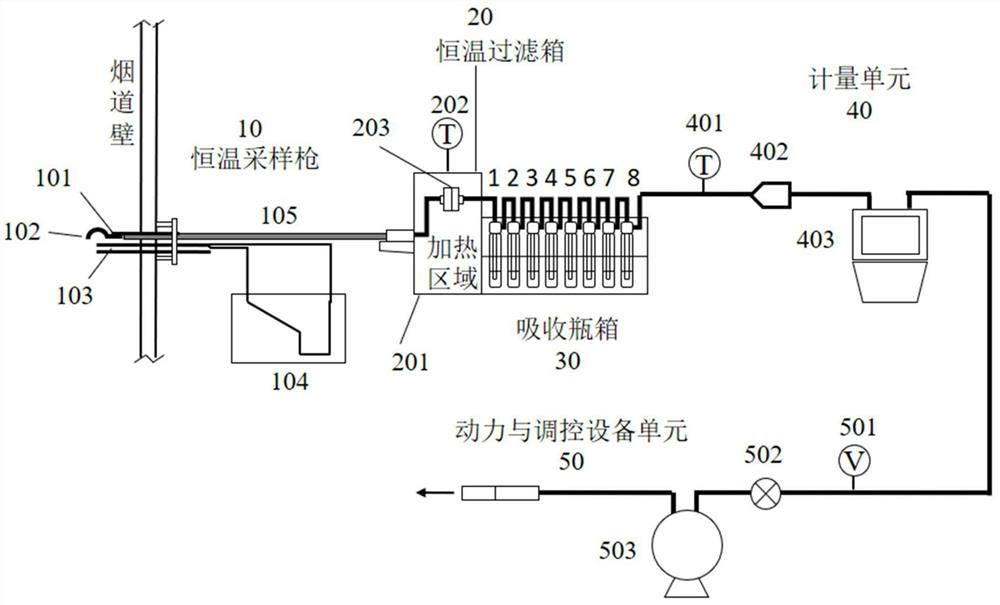

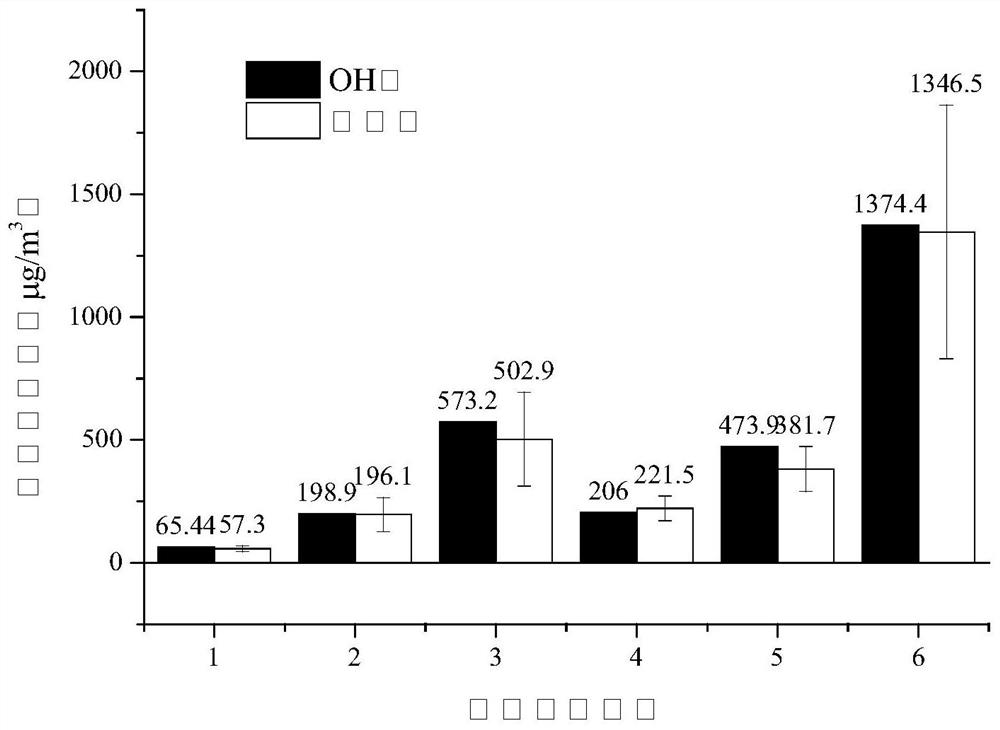

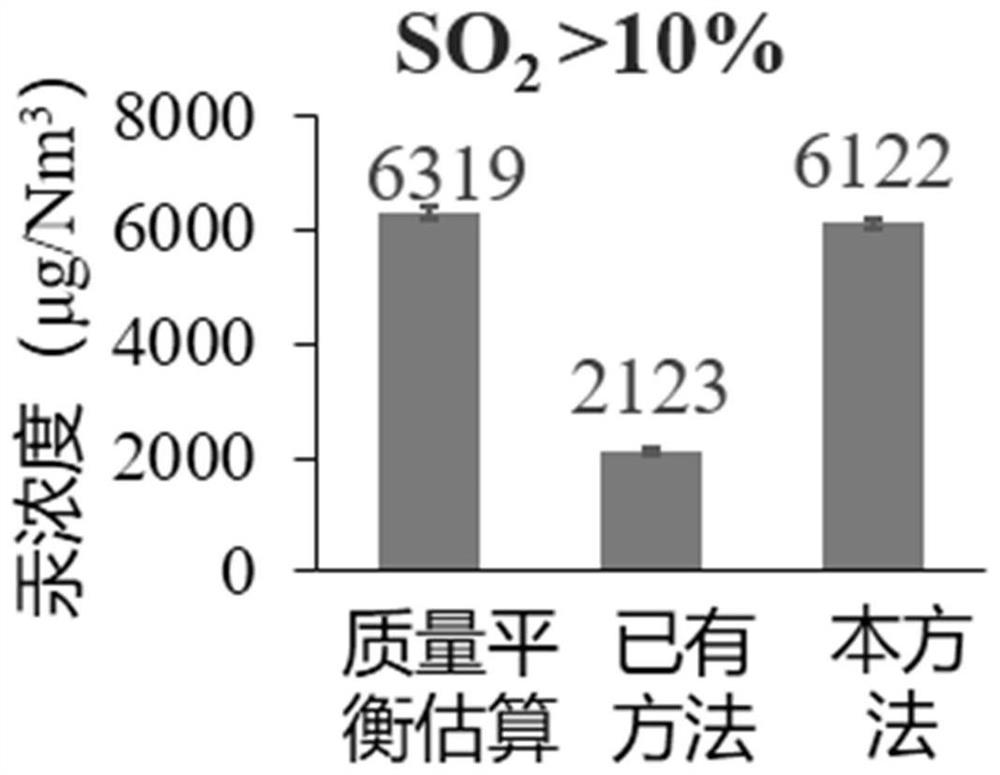

Morphological testing method and device for mercury in full-flow flue gas of stationary pollution source

ActiveCN114487270AFollow-up processing arrangements are reasonableMeet monitoring needsPreparing sample for investigationGas analyser construction detailsProcess engineeringElemental mercury

The invention relates to the technical field of environmental monitoring, in particular to a morphological testing method and a morphological testing device for mercury in full-flow high-SO2 flue gas of a stationary pollution source. The invention provides a method for testing mercury in full-flow flue gas of a stationary pollution source. The method comprises the following steps: collecting mercury in the flue gas through an impact type absorption bottle box; and different absorption bottle combinations are adopted based on different pollution control nodes. By analyzing flue gas components and pollution control nodes in different industries, adjusting the type and concentration of the absorption liquid and screening a proper absorption bottle combination mode on the basis of the existing OH method, the adsorption influence of SO2 on elemental mercury is reduced to the greatest extent, the monitoring accuracy is improved, meanwhile, the post-treatment process of the absorption liquid is simplified, and the production cost is reduced. The treatment cost is reduced. Compared with the existing OH method, the testing method disclosed by the invention not only has good consistency and stability, but also is more flexible in monitoring means and more reasonable in cost, and meets the flue gas mercury monitoring requirements of various complex flue gas systems.

Owner:TSINGHUA UNIV

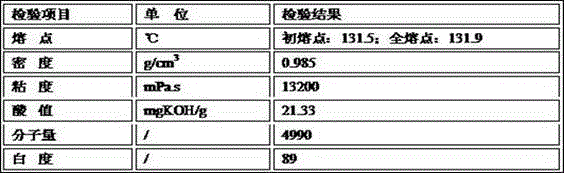

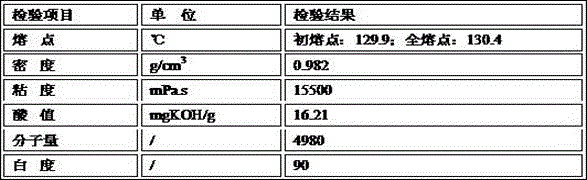

Technological method for preparing novel asphalt modifier with H2O2 as raw material

ActiveCN106220761AReduce production linksImprove yieldBuilding insulationsHigh-density polyethyleneAsphalt

The invention relates to a technological method for preparing a novel asphalt modifier with H2O2 as a raw material. The novel asphalt modifier material adopts low-molecular-weight and high-density polyethylene powder as a raw material. According to the technological method, under a water bath environment, the oxidizing modification reaction is carried out on the polyethylene material with H2O2 as an oxidizing agent by keeping certain pressure and under the effect of a catalyst to prepare the environment-friendly oxidized polyethylene asphalt modifier.

Owner:潍坊大耀新材料有限公司

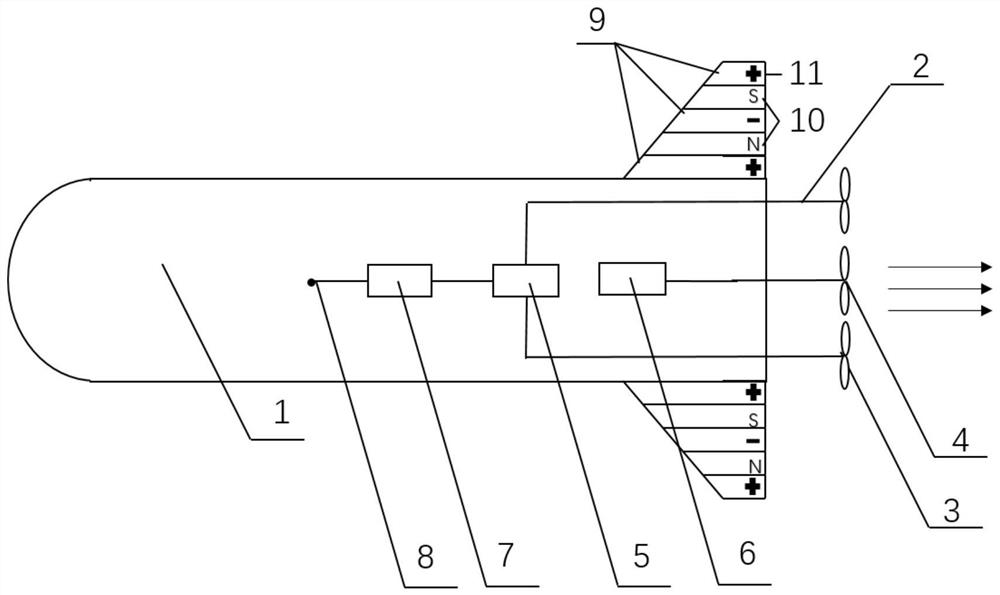

Electromagnetic energy-saving drag reduction device for unmanned underwater vehicle

PendingCN112441203AIncrease motivationReduce resistanceMechanical energy handlingUnderwater vesselsImpellerMagnetic poles

The invention discloses an electromagnetic energy-saving drag reduction device for an unmanned underwater vehicle. The device comprises a power generation module and an electromagnetic drag reductionmodule. The power generation module comprises a generator impeller, a generator impeller fixing support and transmission mechanism and a generator set. The generator impeller is arranged on the outerside of a propeller, the generator impeller fixing support plays a fixing role, the transmission mechanism is connected with one side of the impeller and the generator set, and the generator set is connected with an electric energy output end. The generator impeller is composed of a plurality of impellers, so that residual energy is convenient to collect. The generator set provides electric energyfor the electromagnetic drag reduction module; the electromagnetic control module comprises thin strip-shaped magnets, thin strip-shaped electrodes, a fixing frame and a rechargeable battery, the overall shape of the module is consistent with the shape of an airfoil and is tightly attached to the airfoil of the unmanned underwater vehicle, an electromagnetic activation plate is composed of strip-shaped magnets and strip-shaped electrodes which are arranged at intervals, the polarities of the tops of every two adjacent strip-shaped magnets are opposite, and the polarities of every two adjacentstrip-shaped electrodes are opposite. The thickness of the electrode is equal to that of the magnet, and the electrode and the magnet are fixed and connected through the fixing outer frame. And the electrode magnetic poles are arranged in parallel along the flow direction. The device provides electric energy for the electromagnetic drag reduction module, and the purposes of energy conservation and emission reduction are achieved.

Owner:NANJING UNIV OF SCI & TECH

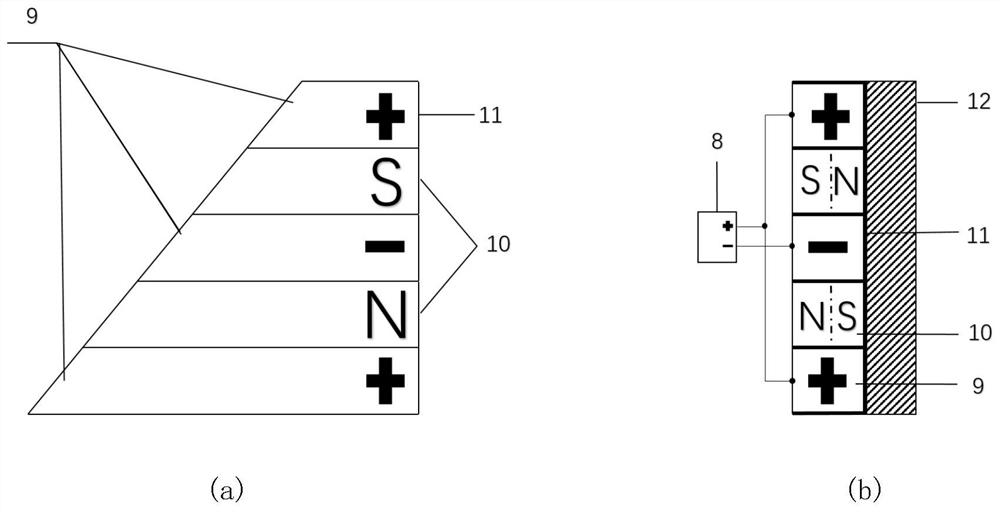

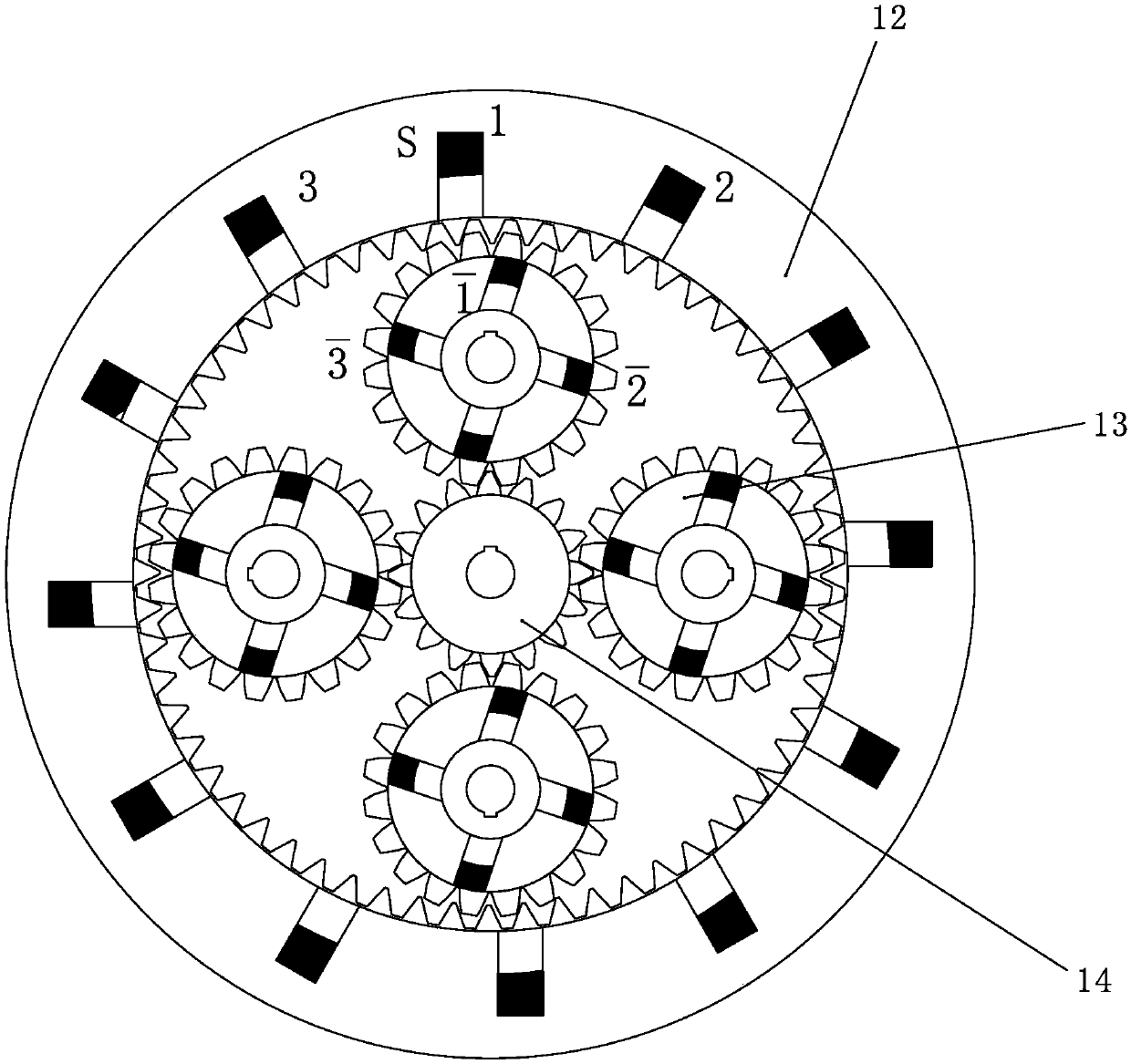

Magnetically-powered automobile with planet magnetic gear driving device

The invention belongs to the technical field of automobile manufacturing and relates to a magnetically-powered automobile with a planet magnetic gear driving device. Structurally, the planet magneticgear driving device is arranged in an automobile and is formed by connecting a planet gear system, a stator shaft, permanent magnets, electromagnets and a miniature generator; after being electrified,the electromagnets generates magnetic pull with the permanent magnets, thereby driving a hub to rotate; magnetic pull between the permanent magnets mounted on gears help the rub operate more stably and more quickly; the planet magnetic gear driving device drives the miniature generator to recycle energy, driving by fuel combustion is replaced, defects of electrical driving are made up, and good energy efficiency and emission reduction are achieved.

Owner:YANGZHOU UNIV

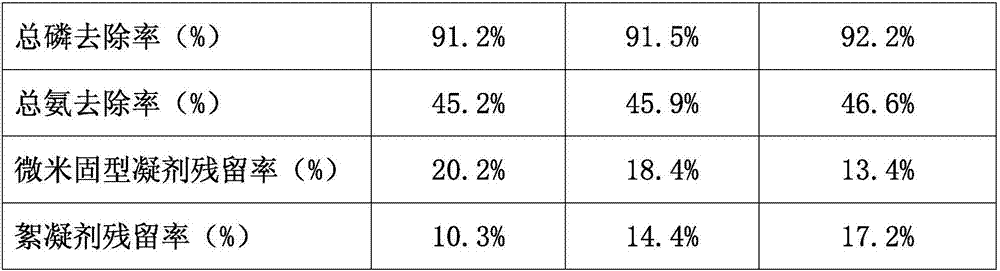

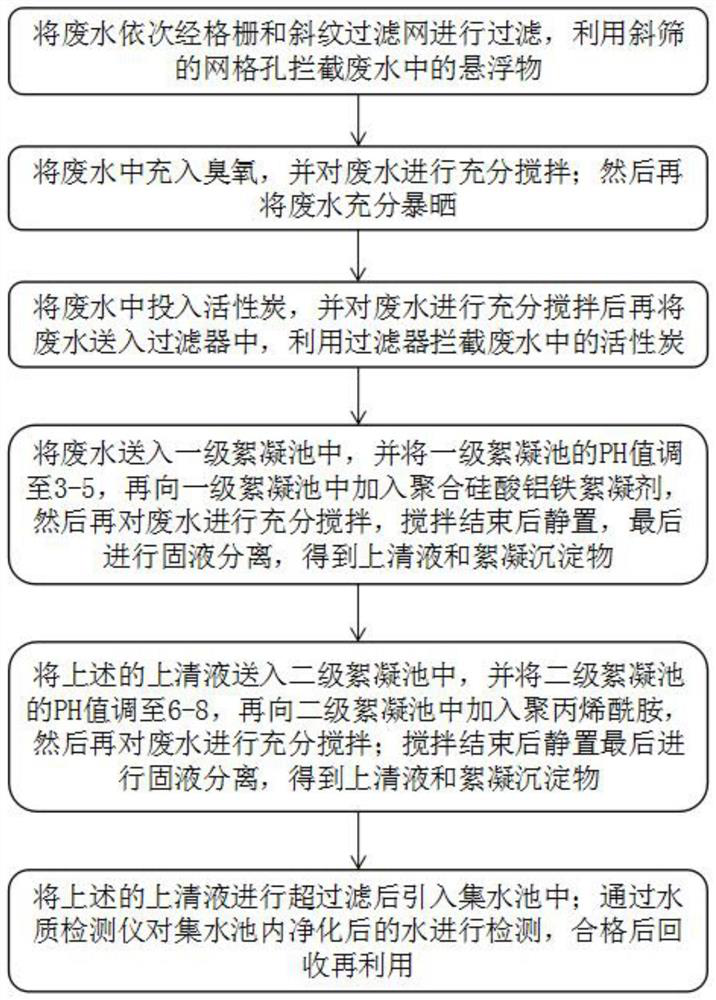

Wastewater advanced treatment process adopting flocculation precipitation method

InactiveCN111635030AEasy to handleStable emissionsGeneral water supply conservationTreatment involving filtrationActivated carbonFlocculation

The invention discloses a wastewater advanced treatment process adopting a flocculation precipitation method, and belongs to the field of sewage treatment. The process comprises the following steps: filtering the wastewater through a grid and a twill filter screen in sequence; introducing ozone into the wastewater, and fully stirring the wastewater; adding activated carbon into the wastewater, fully stirring the wastewater, and filtering; feeding the wastewater into a primary flocculation tank, adding a polysilicate aluminum ferric flocculant into the primary flocculation tank, and finally carrying out solid-liquid separation to obtain a supernatant and a flocculation precipitate; feeding the supernatant into a secondary flocculation tank, adding polyacrylamide into the secondary flocculation tank, and finally performing solid-liquid separation to obtain a supernatant and a flocculation precipitate; and carrying out ultrafiltration, and introducing the supernatant into a water collecting tank. The wastewater is subjected to deep treatment based on the flocculation precipitation method, such that the wastewater treatment effect can be effectively improved; and the process has advantages of simple treatment operation, low cost, no by-product generation and the like, and is suitable for promotion and application.

Owner:安徽洋森环保节能科技有限公司

A process for separating and recovering carbon dioxide from industrial tail gas

ActiveCN103463955BReduce energy consumptionRealize the goal of energy saving and emission reductionProductsReagentsDistillationProcess engineering

The present invention disclosed a process that is separated from the industrial exhaust gas to recycle carbon dioxide. It mainly uses the highly integrated means of energy -heat pump distillation technology.The absorbing solution is contacted to get the rich liquid; the liquid liquid is divided into two shares through the downturn after the liquid pump.Enter the solution tower and absorb, and the carbon dioxide with a small amount of water steam is discharged from the top of the suction tower with a small amount of water steam.use.This process is based on the traditional carbon dioxide capture process, integrates diverting and absorbing and heat pump distillation process, and effectively uses the steam potential heat of the pagoda to reduce the energy consumption during the system operation.Carbon dioxide products reduce greenhouse gas emissions.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com