Wastewater advanced treatment process adopting flocculation precipitation method

A technology of advanced treatment and precipitation, which is applied in the fields of flocculation/sedimentation water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., to achieve the effect of simple treatment operation, high market application value, and energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

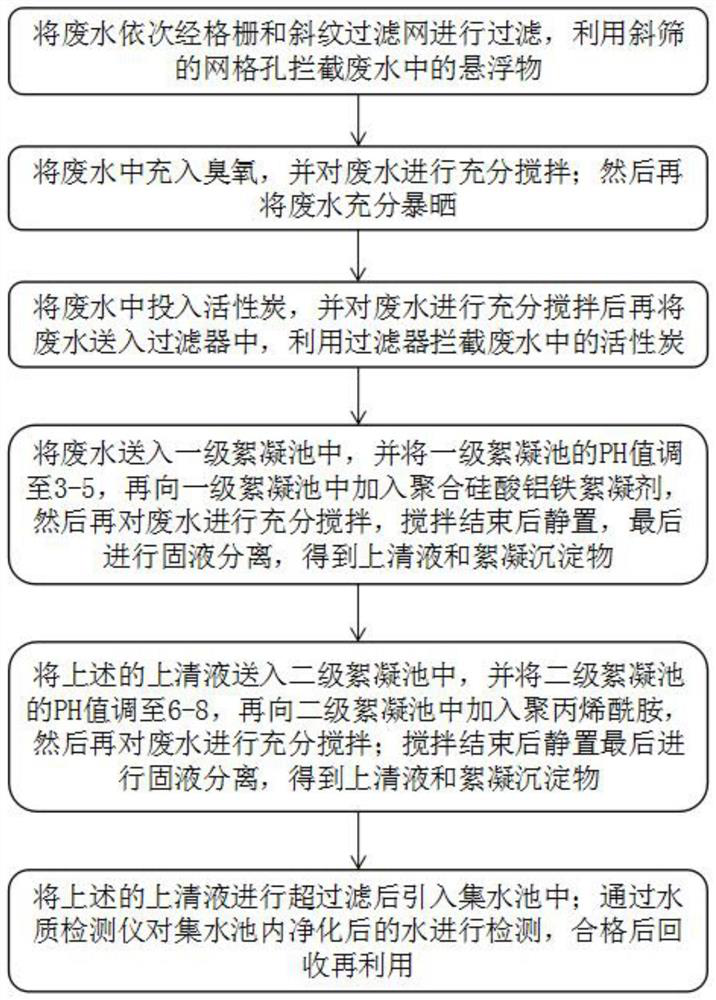

[0025] Such as figure 1 Shown, a kind of wastewater advanced treatment process of flocculation sedimentation method, comprises the following steps:

[0026] Step 1, the waste water is filtered through the grille and the slanted filter in turn, and the suspended matter in the waste water is intercepted by the mesh holes of the slanted screen;

[0027] Step 2, fill the wastewater obtained in Step 1 with ozone, and fully stir the wastewater; the amount of ozone filled is 300 mg / L, and the stirring time is 15 minutes; then the wastewater is fully exposed to the sun; exposed to the sun for 24 hours;

[0028] Step 3, put the wastewater obtained in step 2 into activated carbon, and fully stir the wastewater; the input amount of activated carbon is 500g / L, and the stirring time is 15min; then the wastewater is sent into the filter, and the filter is used to intercept the waste water. Activated carbon;

[0029] Step 4, send the wastewater obtained in step 3 into the primary flocculat...

specific Embodiment 2

[0037] Such as figure 1 Shown, a kind of wastewater advanced treatment process of flocculation sedimentation method, comprises the following steps:

[0038] Step 1, the waste water is filtered through the grille and the slanted filter in turn, and the suspended matter in the waste water is intercepted by the mesh holes of the slanted screen;

[0039] Step 2, fill the wastewater obtained in Step 1 with ozone, and fully stir the wastewater; the amount of ozone filled is 300 mg / L, and the stirring time is 22.5 minutes; then the wastewater is fully exposed to the sun; exposed to the sun for 36 hours;

[0040] Step 3: Put the wastewater obtained in Step 2 into activated carbon, and fully stir the wastewater; the input amount of activated carbon is 500g / L, and the stirring time is 22.5min; then send the wastewater into the filter, and use the filter to intercept the waste water activated carbon;

[0041] Step 4, send the wastewater obtained in step 3 into the first-level flocculat...

specific Embodiment 3

[0049] Such as figure 1 Shown, a kind of wastewater advanced treatment process of flocculation sedimentation method, comprises the following steps:

[0050] Step 1, the waste water is filtered through the grille and the slanted filter in turn, and the suspended matter in the waste water is intercepted by the mesh holes of the slanted screen;

[0051] Step 2, fill the wastewater obtained in Step 1 with ozone, and fully stir the wastewater; the amount of ozone filled is 300 mg / L, and the stirring time is 30 minutes; then fully expose the wastewater to the sun; expose to the sun for 48 hours;

[0052] Step 3, put the wastewater obtained in step 2 into activated carbon, and fully stir the wastewater; the input amount of activated carbon is 500g / L, and the stirring time is 30min; then the wastewater is sent into the filter, and the filter is used to intercept the waste water. Activated carbon;

[0053] Step 4, send the wastewater obtained in step 3 into the primary flocculation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com