Morphological testing method and device for mercury in full-flow flue gas of stationary pollution source

A technology for fixing pollution sources and testing methods, applied in the field of environmental monitoring, can solve the problems of cumbersome treatment process, complex components, low upper limit of anti-interference concentration, etc., and achieve the effects of flexible collection methods, reduced corrosion loss, and reasonable follow-up treatment arrangements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

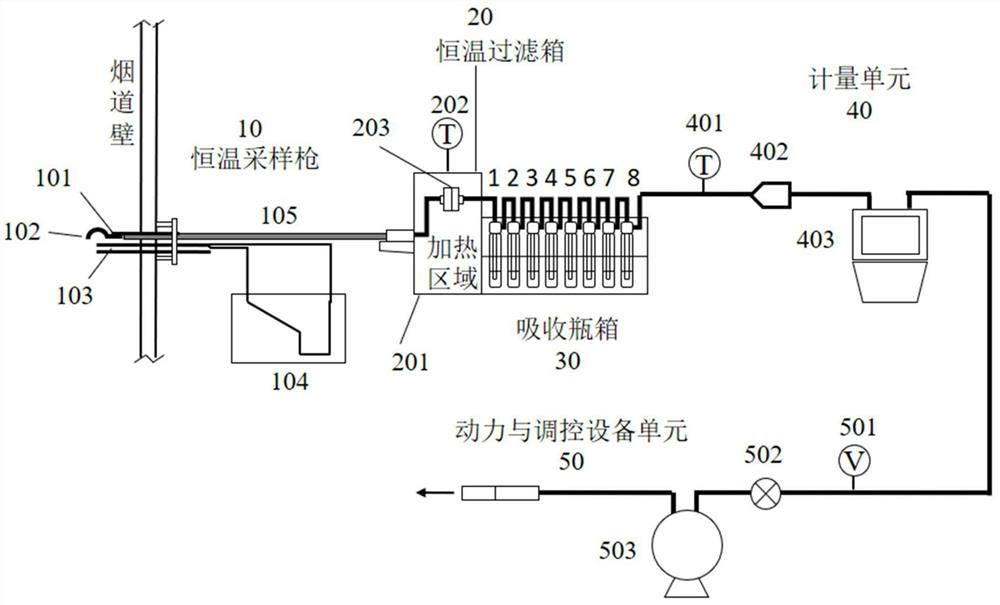

[0038] This embodiment provides a fractal form testing device for the whole process flue gas mercury of a fixed pollution source, such as figure 1 shown, including:

[0039] Thermostatic sampling gun 10 (101 thermocouple, 102 sampling nozzle, 103 pitot tube, 104 pressure gauge and 105 high-sprayed silicon glass or quartz sampling liner);

[0040] Constant temperature filtration unit (constant temperature filter box) 20 (201 heating box, 202 membrane tray, 203 quartz filter membrane, the diameter of the filter membrane is 83mm, and the blocking efficiency of particles with a particle size greater than 0.3μm is not less than 99.95%);

[0041] Impact absorption bottle box 30;

[0042] Metering unit 40 (401 thermocouple, check valve 402 and dry gas meter 403);

[0043] Power and regulation equipment unit 50 (vacuum gauge 501, main valve 502 and vacuum pump 503).

Embodiment 2

[0045] This embodiment provides a morphological testing method for mercury in the flue gas of a fixed pollution source, including: sampling, filtering, collecting, measuring, and regulating the flue gas using the testing device described in Example 1;

[0046] Among them, the collection adopts the impact absorption bottle box; different combinations of absorption bottles are used based on different pollution control nodes; among them:

[0047] (1) Conventional process flue gas refers to process flue gas in fixed pollution sources such as coal burning, cement, incineration, etc. The process refers to the process before and after denitrification, desulfurization, and dust removal of flue gas; SO 2 compositional characteristics.

[0048] (2) The smelting flue gas before the colored acid production has a high concentration of SO 2 compositional characteristics.

[0049] (3) After desulfurization, the tail gas has a lower concentration of SO 2 compositional characteristics.

...

experiment example 1

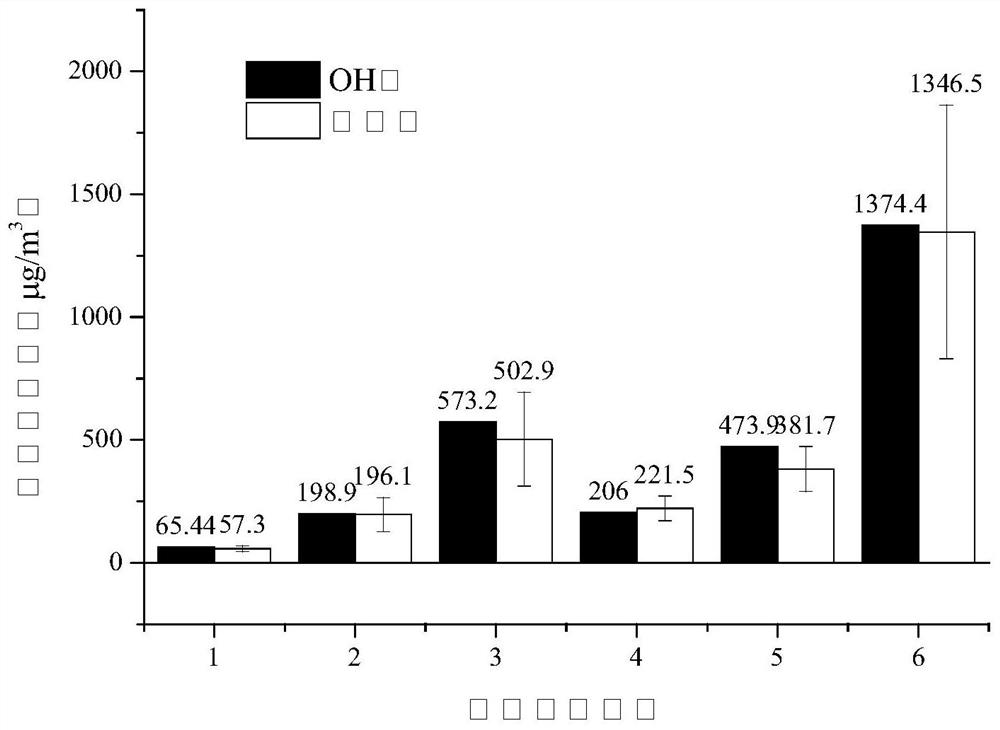

[0054] Taking the whole process flue gas at the kiln tail of a certain cement factory as an example, the mercury concentration in the flue gas was tested by using the test method of the present invention and the OH method.

[0055] The flue gas at the kiln tail has complex components. Based on this, the combination of absorption liquids corresponding to the conventional process flue gas in Table 1 was selected for testing, namely: 3 bottles of 100ml 1.5mol / L KOH absorption liquid + 1 bottle of 100ml 10%H 2 o 2 -HNO 3 Absorption solution + 3 bottles of 100ml 4% KMnO 4 -10%H 2 SO 4 +1 bottle of silicone.

[0056] The conventional absorption solution for the OH method: 3 bottles of 100ml 1mol / L KCl absorption solution + 1 bottle of 100ml 10%H 2 o 2 -5%HNO 3 Absorption solution + 3 bottles of 100ml 4% KMnO 4 -10%H 2 SO 4 +1 bottle of silicone.

[0057] The result is as figure 2 Shown:

[0058] 6 groups of results of OH method test from 65.4μg / m 3 to 1374.4μg / m 3 sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com