Technological method for preparing novel asphalt modifier with H2O2 as raw material

An asphalt modifier, H2O2 technology, applied in building thermal insulation materials, building components, buildings and other directions, can solve the problems of complex process and low yield rate, and achieve the effects of uniform reaction, high yield rate and few production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

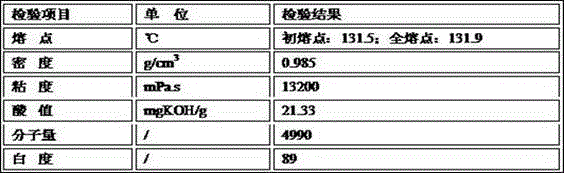

[0028] Example 1, a kind of H 2 o 2 A process for preparing a novel asphalt modifier for raw materials, comprising the following steps:

[0029] 1) Mix 300kg of low molecular weight, high density polyethylene powder, 600kg of deionized water, industrial H 2 o 2 Add 100kg of water, 0.6kg of polymerization inhibitor, 0.6kg of metallocene catalyst, 0.6kg of surfactant, etc. into the high-temperature pressure reaction kettle, stir for 30min, and make a suspension turbid liquid;

[0030] 2) Heating the suspended turbid liquid, the heating rate is controlled at 1.5°C / min, while stirring continuously, the rotating speed is 300r / min;

[0031] 3) Pressurize and heat up, and the pressure reaches 8.104×10 5 When the pressure is high, stop pressurizing, heat up to 120°C, hold for 72 hours, and keep stirring during the hold;

[0032] 4) Cooling and filtering: After the heat preservation and stirring period is over, it is cooled to room temperature naturally; the suspension after cooli...

Embodiment 2

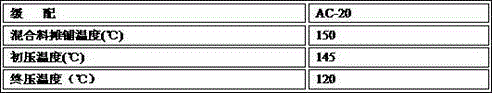

[0038] Example 2, a kind of H 2 o 2 A process for preparing a novel asphalt modifier for raw materials, comprising the following steps:

[0039] 1) Mix 300kg of low molecular weight, high density polyethylene powder, 600kg of deionized water, industrial H 2 o 2 Add 150kg of water, 4.5kg of polymerization inhibitor, 6.0kg of metallocene catalyst, and 4.5kg of surfactant into a high-temperature pressure reactor, and stir for 30 minutes to make a suspension turbidity.

[0040] 2) Heating the suspended turbid liquid, the temperature rate is controlled at 1.5°C / min, and the temperature is kept while stirring continuously, and the rotation speed is 500r / min;

[0041] 3) Pressurize and heat up, and the pressure reaches 8.104×10 5 When the pressure is high, stop pressurizing, heat up to 120°C, hold for 72 hours, and keep stirring during the hold;

[0042] 4) Cooling and filtering: After the heat preservation and stirring period is over, the temperature is naturally lowered to roo...

Embodiment 3

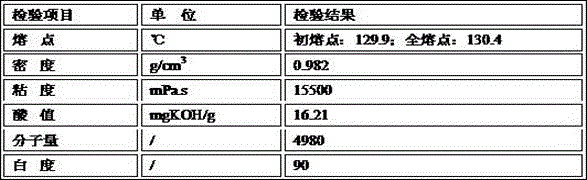

[0048] Example 3, a kind of H 2 o 2 A process for preparing a novel asphalt modifier for raw materials, comprising the following steps:

[0049] 1) Mix 300kg of low molecular weight, high density polyethylene powder, 600kg of deionized water, industrial H 2 o 2 Add 110kg of water, 1.5kg of polymerization inhibitor, 1.5kg of metallocene catalyst, and 1.5kg of surfactant into the high-temperature pressure reaction kettle, stir for 30min, and make a suspension turbid liquid.

[0050] 2) Heating the suspended turbid liquid, the heating rate is controlled at 1.5°C / min, while stirring continuously, the rotating speed is 500r / min;

[0051] 3) Pressurize and heat up, and the pressure reaches 8.104×10 5 When the pressure is high, stop pressurizing, heat up to 120°C, hold for 72 hours, and keep stirring during the hold;

[0052] 4) Cooling and filtering: After the heat preservation and stirring period is over, the temperature is naturally lowered to room temperature; after cooling, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acidity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com