Internal circulation dry-process purification technology and equipment

A dry purification and internal circulation technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve operation management, maintenance and maintenance difficulties, increase system and equipment operation management costs, and affect dry purification systems. Adsorption performance and other issues, to achieve the effect of reducing initial investment and operation management and maintenance costs, reducing initial investment and operating costs, reducing floor space and system pipeline occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with specific embodiments.

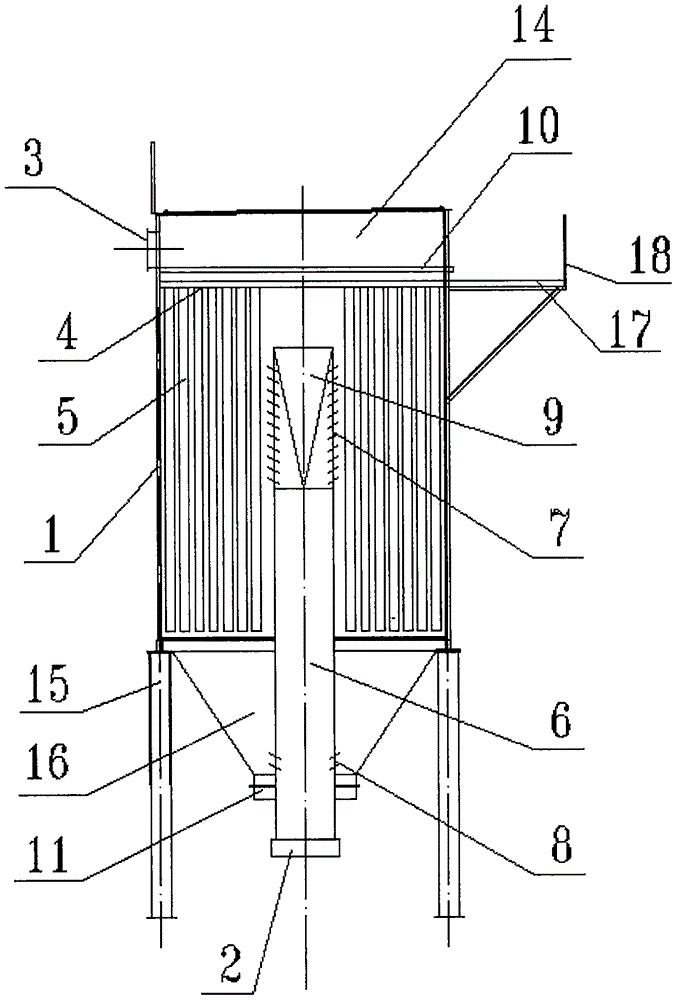

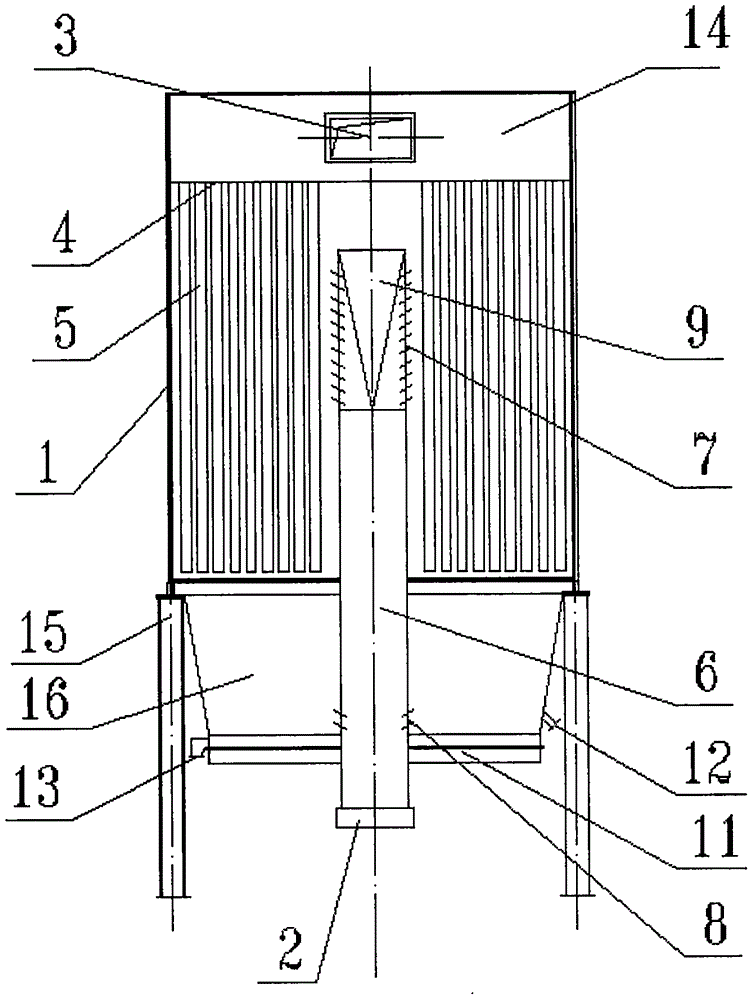

[0019] Reference Figure 1-2 , An internal-circulation dry purification equipment proposed by the present invention includes a clean air chamber 14, a bag filter box 1, a material collection device 16, and a support device 15. A clean air chamber 14 is installed on the top of the bag filter box 1 A compressed air blowback ash cleaning system 10 is installed in the clean air chamber 14. The compressed air blowback ash cleaning system 10 includes an air bag, a pulse valve, and a blow pipe. One end of the pulse valve is connected to the air bag, and the other end Connected with a blow pipe, an overhaul platform 17 is installed on the side wall of the bag filter box 1, and a railing 18 is installed outside the overhaul platform 17, and a material collection device 16 is installed at the bottom of the bag filter box 1, and a bag filter The box body 1 is in communication with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com