A process for separating and recovering carbon dioxide from industrial tail gas

A carbon dioxide and industrial exhaust gas technology, applied in separation methods, dispersed particle separation, educts, etc., can solve the problems of high compression power consumption, not reducing operating energy consumption, etc., to reduce energy consumption, reduce operating costs, and reduce heat consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

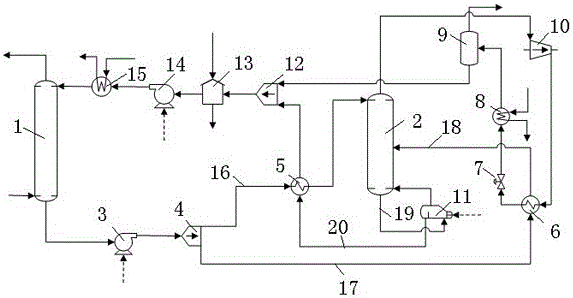

[0033] Such as figure 1 As shown, a process for separating and recovering carbon dioxide from industrial tail gas includes absorption tower 1 and desorption tower 2, and the specific process steps are:

[0034]1) The pretreated industrial tail gas enters the bottom of the absorption tower 1, flows upwards in the absorption tower, and contacts with the absorption liquid entering from the top of the absorption tower 1 countercurrently, and the carbon dioxide is absorbed by the absorption liquid to obtain a rich liquid; The carbon tail gas is directly discharged from the top of the absorption tower 1; the absorption liquid is a monoethanolamine solution with a mass concentration of 20%-50%, and the temperature of the absorption liquid is 30°C-50°C;

[0035] 2) The rich liquid passes through the rich liquid pump 3 and then is divided into two parts by the flow divider 4, the first rich liquid and the second rich liquid, wherein the molar percentage of the second rich liquid in th...

Embodiment 2

[0042] Other processes are the same as in Example 1, when the compressor pressure change is 40KPa, the minimum total operating energy consumption is 0.365 GJ / t CO 2 , compared with the traditional process, reduced by 34.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com