Method for treating printing and dyeing wastewater

A technology for printing and dyeing wastewater and a treatment method, which is applied to the treatment of printing and dyeing wastewater and wastewater treatment fields, can solve the problems of only removal rate, complex process and high cost, and achieve the effect of improving the recycling rate and unifying environmental benefits and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

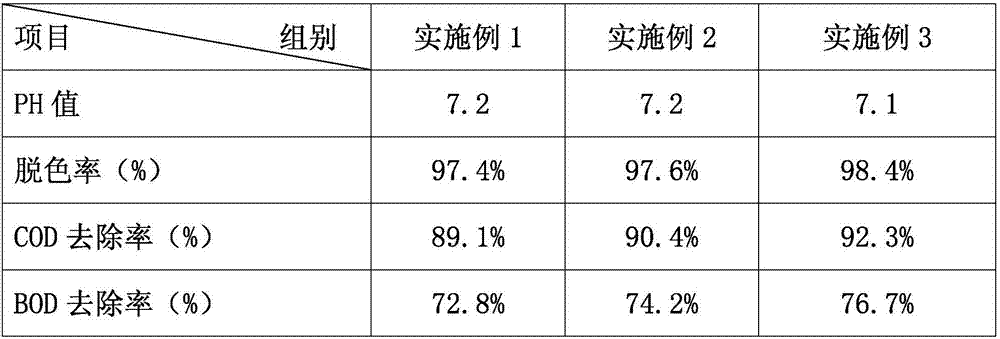

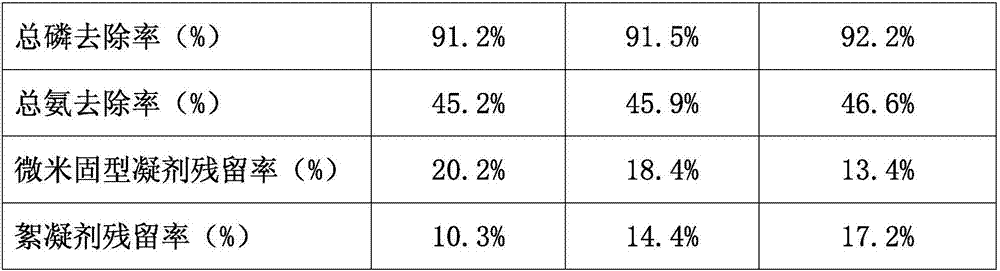

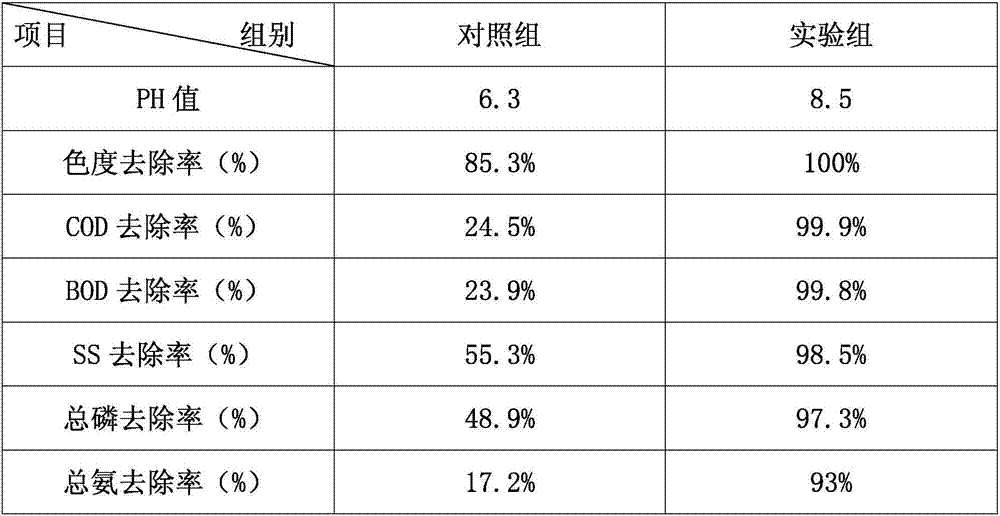

Embodiment 1

[0017] A treatment method for printing and dyeing wastewater, comprising the following steps:

[0018] 1) Grille and screen to remove impurities: First, the rotary grid machine is used to intercept the larger suspended matter in the printing and dyeing wastewater, and the larger suspended matter in the wastewater is picked up by the scooping machine to keep the waste water flowing smoothly, and then pass through The screen intercepts the fine suspended matter in the waste water, picks up the fine suspended matter in the waste water through the fine matter salvage tool, and introduces the waste water behind the screen into the advection grit chamber;

[0019] 2) Grit treatment: the wastewater stays in the advection grit chamber for 2 hours to settle the silt particles, finally remove the silt in the wastewater, and introduce the grit-set wastewater into the flocculation tank;

[0020] 3) Flocculation and sedimentation: Add 72 parts of high-efficiency flocculant to each cubic me...

Embodiment 2

[0030] A treatment method for printing and dyeing wastewater, comprising the following steps:

[0031] 1) Grille and screen to remove impurities: First, the rotary grid machine is used to intercept the larger suspended matter in the printing and dyeing wastewater, and the larger suspended matter in the wastewater is picked up by the scooping machine to keep the waste water flowing smoothly, and then pass through The screen intercepts the fine suspended matter in the waste water, picks up the fine suspended matter in the waste water through the fine matter salvage tool, and introduces the waste water behind the screen into the advection grit chamber;

[0032] 2) Grit treatment: the wastewater stays in the advection grit chamber for 2 hours to settle the silt particles, finally remove the silt in the wastewater, and introduce the grit-set wastewater into the flocculation tank;

[0033] 3) Flocculation and sedimentation: Add 49 parts of high-efficiency flocculant to each cubic me...

Embodiment 3

[0043] A treatment method for printing and dyeing wastewater, comprising the following steps:

[0044] 1) Grille and screen to remove impurities: First, the rotary grid machine is used to intercept the larger suspended matter in the printing and dyeing wastewater, and the larger suspended matter in the wastewater is picked up by the scooping machine to keep the waste water flowing smoothly, and then pass through The screen intercepts the fine suspended matter in the waste water, picks up the fine suspended matter in the waste water through the fine matter salvage tool, and introduces the waste water behind the screen into the advection grit chamber;

[0045] 2) Grit treatment: the wastewater stays in the advection grit chamber for 2 hours to settle the silt particles, finally remove the silt in the wastewater, and introduce the grit-set wastewater into the flocculation tank;

[0046] 3) Flocculation and sedimentation: Add 62 parts of high-efficiency flocculant to each cubic mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com