Combined spring support device

A technology of support device and combined spring, which is applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve the problem that the turbine shell and surrounding pipelines are prone to vibration, unable to operate normally and continuously to generate electricity, and affect the turbine. The machine service life and other issues, to eliminate vibration, reduce the level of friction, improve the performance of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

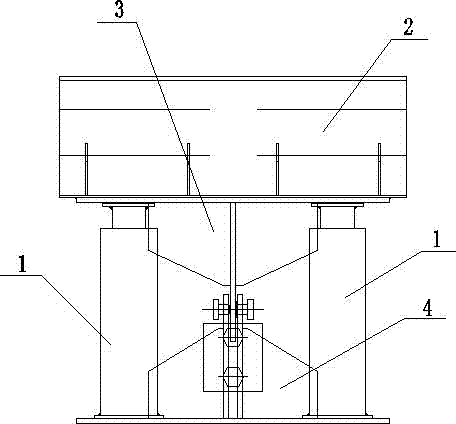

[0036] As shown in the figure, a combined spring support device includes two spring supports 1, a riser elbow support 2, an upper rigid body 3 and a lower rigid body 4;

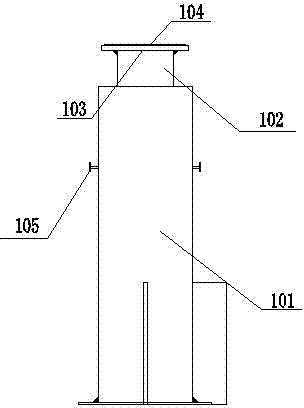

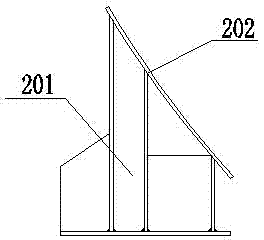

[0037] The lower rigid body 4 includes a lower base plate 401 and two lower vertical plates 402 vertically arranged on the lower base plate. The spacing between the two lower vertical plates 402 is equal, and the two spring supports 1 are symmetrically distributed on both sides of the lower rigid body 4. The spring bracket 1 is also arranged on the lower bottom plate 401. The upper rigid body 3 includes an upper support plate 301 and an upper vertical plate 302 vertically arranged on the upper support plate. The two ends of the upper support plate 301 are pressed on both sides of the lower rigid body. On the load plate 103 of the spring support 1, an upper friction pair is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com