Contact surface friction force measuring device

A measuring device and friction force technology, applied in the field of contact surface friction force measuring devices, can solve problems such as urgent need and few sensors, and achieve the effect of realizing health monitoring, reducing friction force, and avoiding direct contact with rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

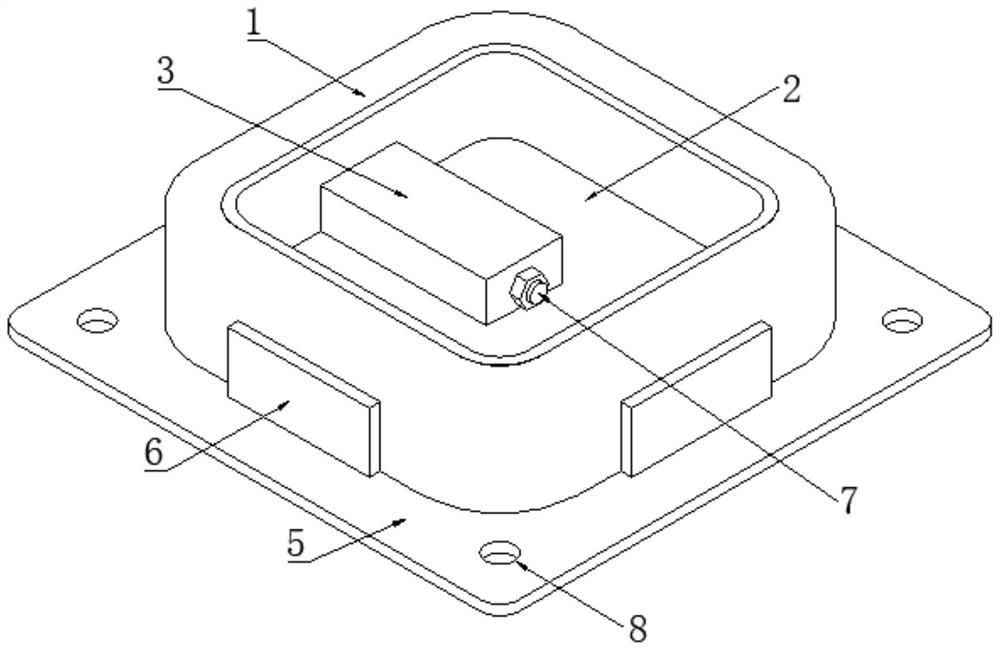

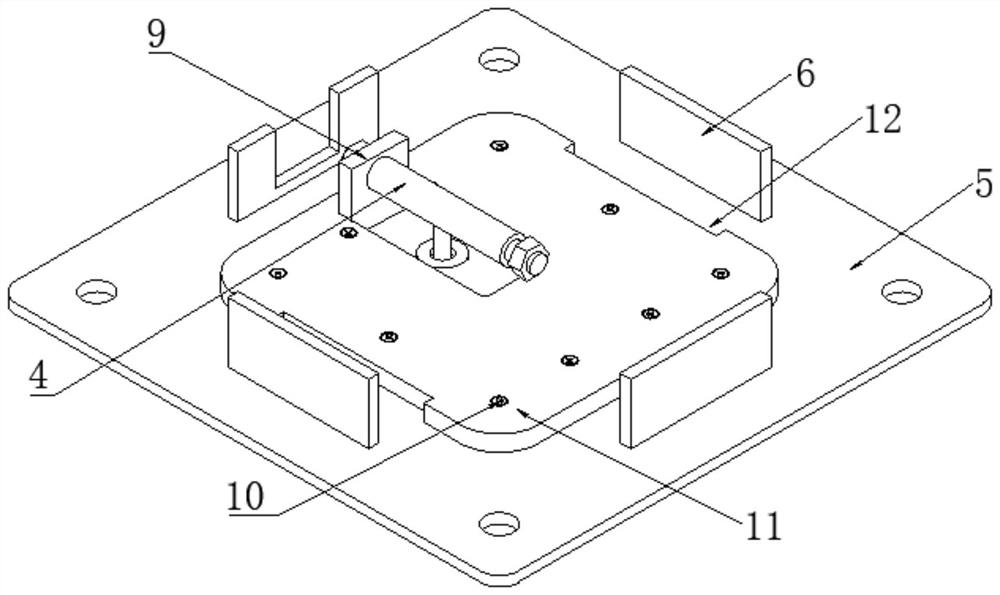

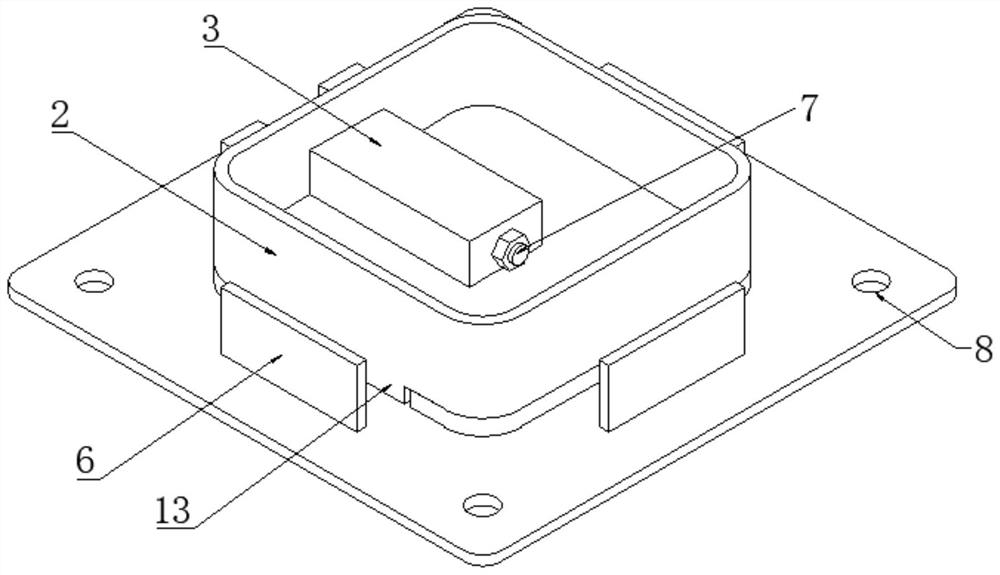

[0044] The contact surface friction measurement device of this embodiment includes a measuring mechanism for measuring the contact surface friction, a fixed support mechanism for fixing and supporting the measuring mechanism, and a block for eliminating the influence of pressure around the measuring mechanism mechanism; both the measuring mechanism and the blocking mechanism are fixedly installed on the fixed supporting mechanism, and the measuring mechanism is located in the space surrounded by the blocking mechanism, the fixed supporting mechanism and the surrounding rock; as Figure 5 As shown, the measuring mechanism includes a sliding backing plate 11, a friction box 2 and an inductor 4, the blocking mechanism includes a plastic casing 1 and a plastic casing limit baffle 6 located around the plastic casing 1, and the fixed The support mechanism includes a base tray 5 and a base fixing steel bar 16 .

[0045] Such as figure 2 and image 3 As shown, the sliding backing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com