Pump health monitoring method, system and equipment based on edge calculation and medium

An edge computing and health monitoring technology, applied in mechanical equipment, pump testing, machine/engine, etc., can solve problems such as large memory consumption, failure to actively grasp equipment health status, slow analysis speed, etc., to improve analysis speed and reduce memory The effect of consumption and reduction of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

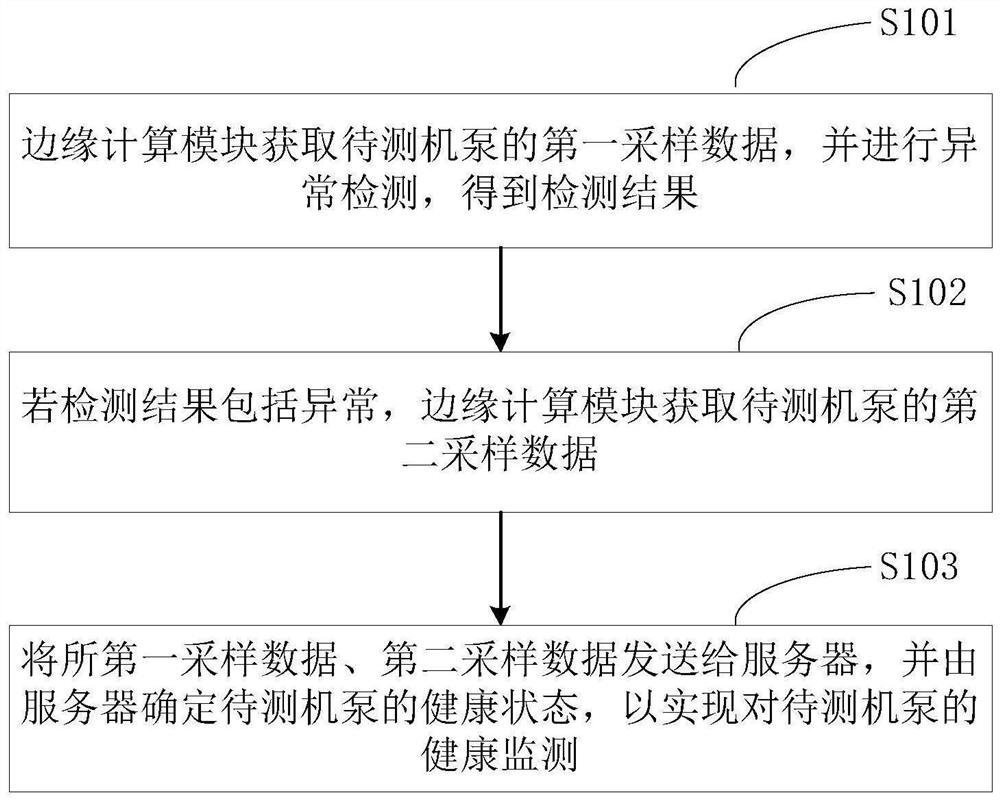

[0059] Such as figure 1 As shown, this embodiment provides a method for monitoring the health of a pump based on edge computing, which includes:

[0060] Step S101: The edge computing module acquires the first sampling data of the pump under test, and performs anomaly detection to obtain a detection result.

[0061] Wherein, the first sampling data includes at least one of vibration data, stress wave data and temperature data, and the detection result includes normal or abnormal.

[0062] The first sampling data may be collected by one or more preset sampling devices.

[0063] In one embodiment, an optional manner of performing anomaly detection on the first sampled data includes:

[0064] A first sampling threshold is acquired, the first sampling data is compared with the first sampling threshold, and the comparison result is used as a detection result.

[0065] It can be preset that the detection result is normal or abnormal when the first sampling data is higher or lower...

Embodiment 2

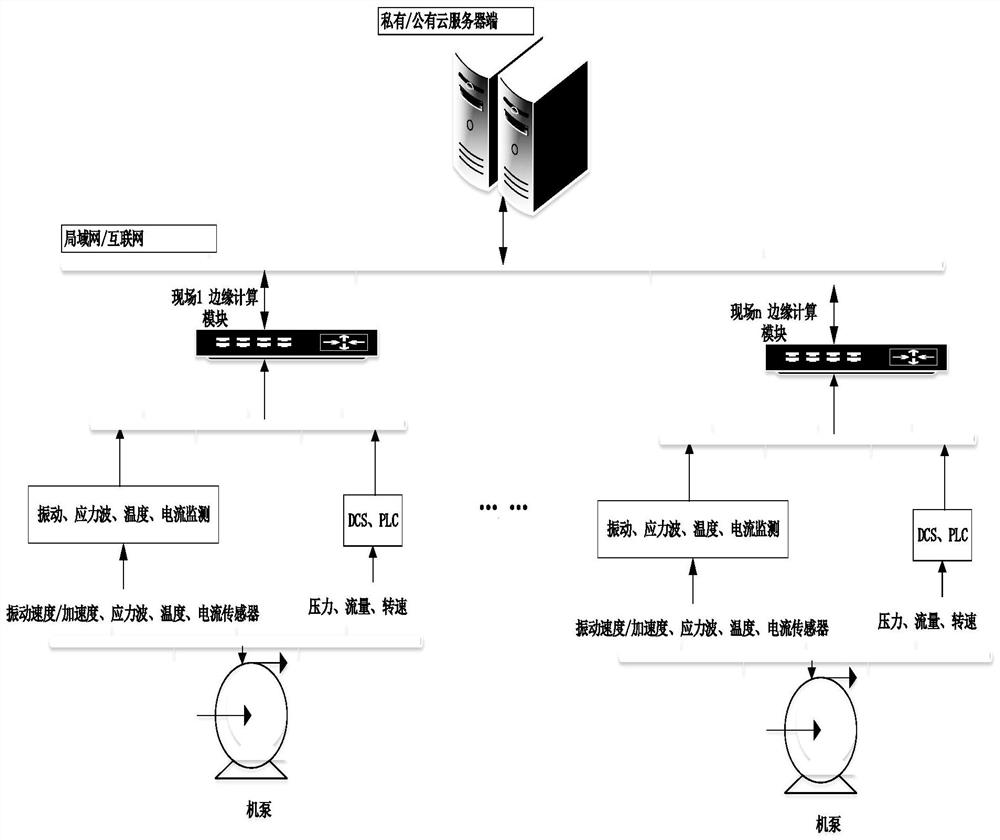

[0149] see Figure 4 , this embodiment provides a machine pump health monitoring system 400 based on edge computing, including:

[0150] The data acquisition module 401 is configured to acquire first sampling data and second sampling data of the pump to be tested, the first sampling data includes at least one of vibration data, stress wave data and temperature data, and the second sampling includes current data, pressure data At least one of data and traffic data;

[0151] The edge calculation module 402 is used to obtain the first sampled data, and perform anomaly detection to obtain a detection result, the detection result includes normal or abnormal, if the detection result includes abnormality, obtain the second sampled data, and combine the first sampled data, the second The sampling data is sent to the server;

[0152] The server 403 is configured to determine the health status of the pump under test, so as to realize the health monitoring of the pump under test.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com