A multipurpose on-site shearing instrument and method

A multi-purpose, on-site technology, applied to instruments, scientific instruments, and the use of stable shear force to test the strength of materials, etc., can solve the problems of large disturbance measurement results, non-representative field test errors, small sample size, etc. Achieve the effect of avoiding inaccurate pressure measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

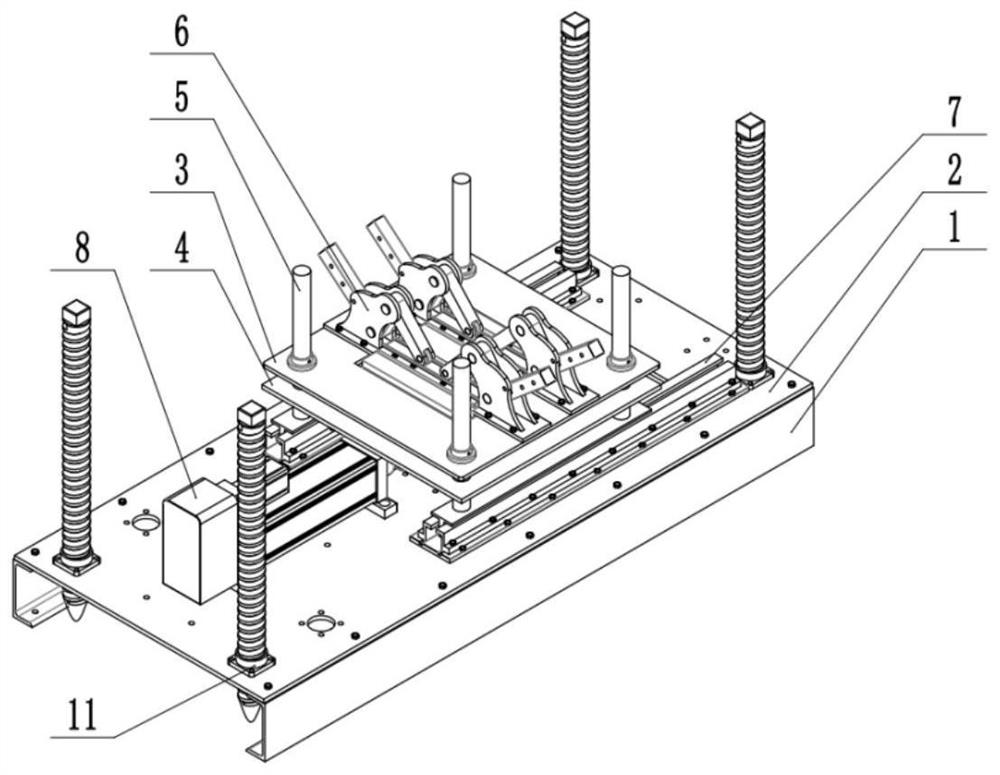

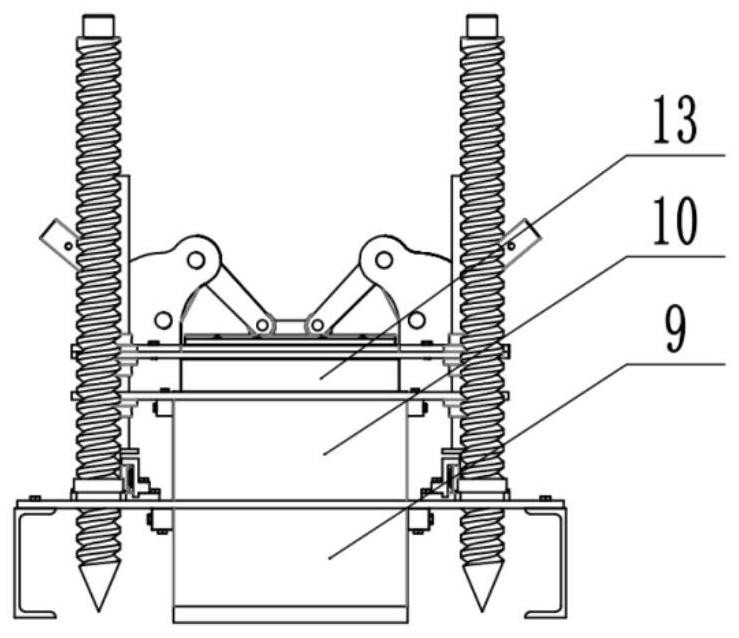

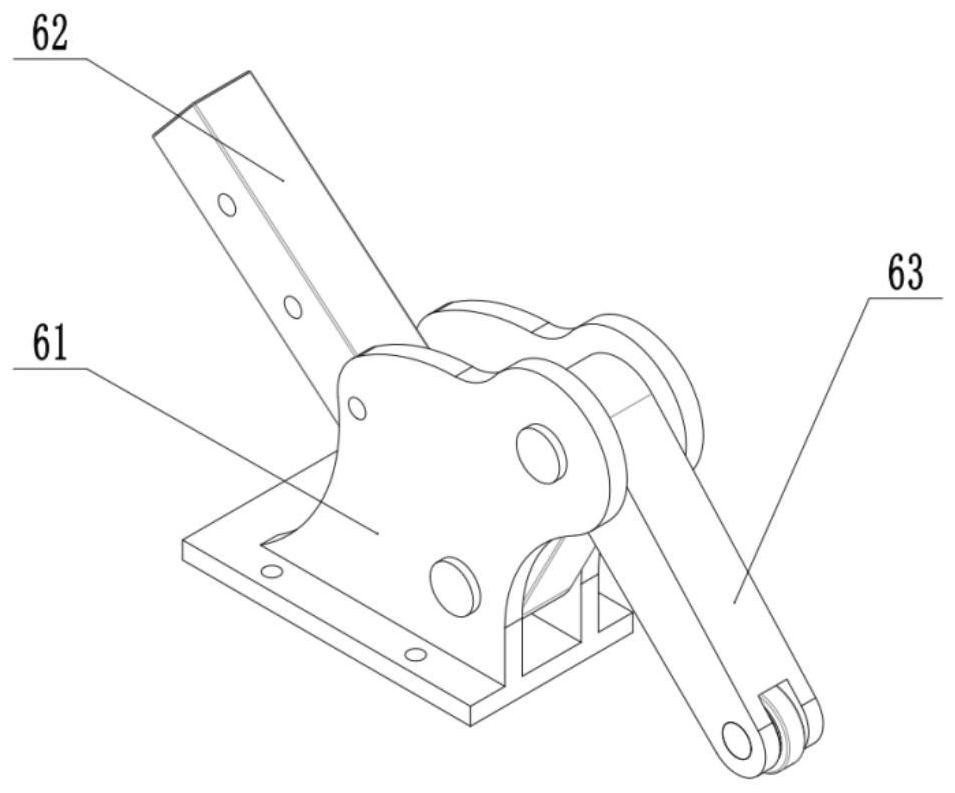

[0046] like Figure 1-12As shown, the present invention provides a multi-purpose on-site shearing instrument, including a base, a slide rail device 7, a loading device, and a driving device 8 arranged on the upper end face of the base, wherein the base is provided with a through hole through which the shearing box can pass, The shearing box includes an upper shearing box 10 and a lower shearing box 9. Two sliding rail devices 7 are symmetrically arranged on both sides of the through hole along the length direction of the base. The loading device is arranged above the sliding rail device 7 and is connected with the sliding rail device 7. The rail device 7 is slidably connected, and the loading device is provided with a through hole for placing the loading box cover 13, and the loading box cover 13 is detachably connected to the upper part of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com