A kind of testing device and testing method of mortar constructability

A test method and constructible technology, applied in measuring devices, flow characteristics, instruments, etc., can solve the problems such as the inability of accurate readings by the spring tension meter, the error of the measurement results, and the incomparability of the measurement results, so as to reduce the test results. Influence, reduce horizontal friction, improve the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

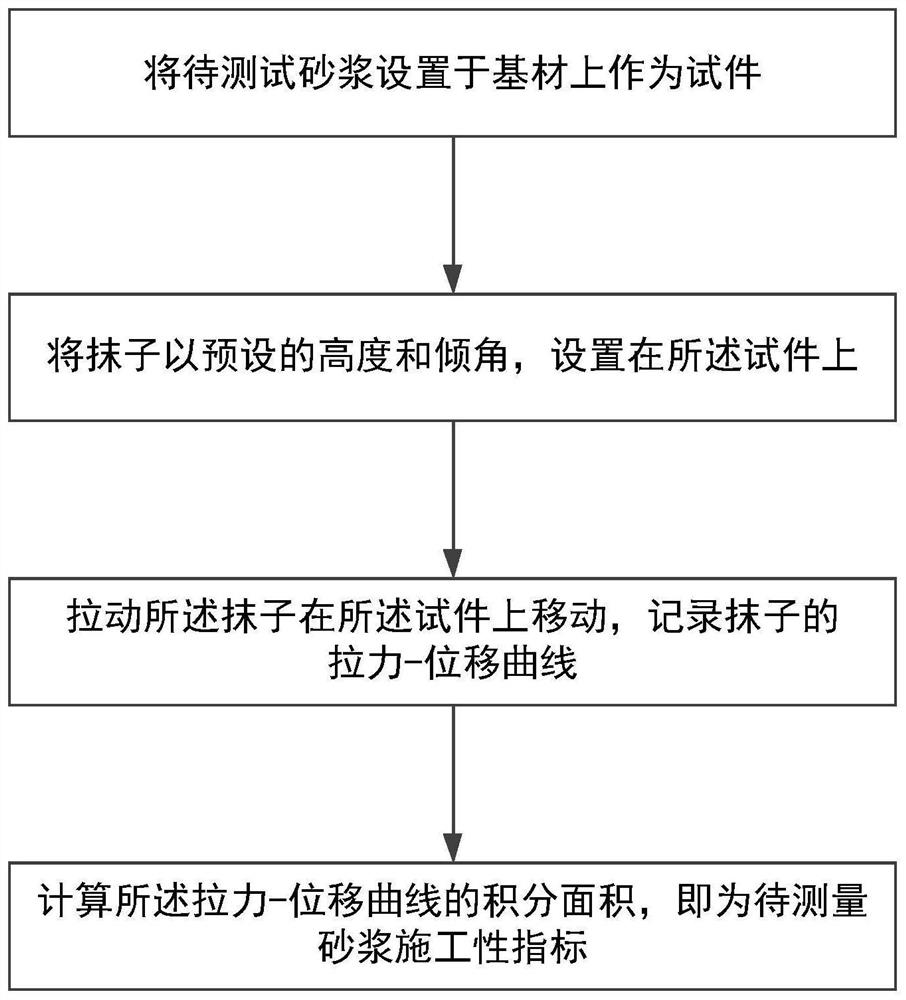

[0032] This example provides a test method for mortar construction.

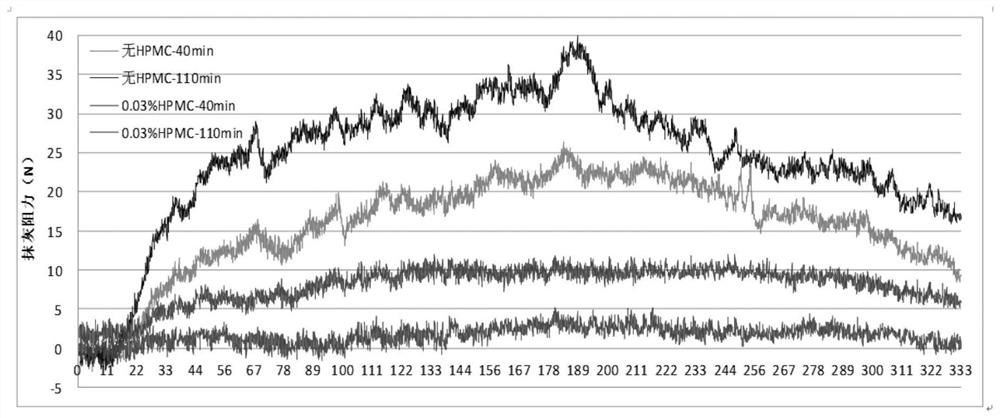

[0033] Such as figure 1 Shown, a kind of mortar constructability testing method comprises the following steps: (1) setting the mortar to be tested on the substrate as a test piece; (2) setting the trowel on the test piece with a preset height and inclination angle (3) pull the trowel to move on the test piece, record the tension-displacement curve of the trowel; (4) calculate the integral area of the tension-displacement curve, which is the construction index of the mortar to be measured . As the trowel moves, more and more mortar is accumulated in front of it, which causes its pulling force to gradually increase. It is difficult to fully reflect the mortar construction performance of the entire test process only through the tension at one point. Therefore, this method adopts the technical scheme of calculating the integral area of the tension-displacement curve, and uses the integral area as an evalua...

Embodiment 2

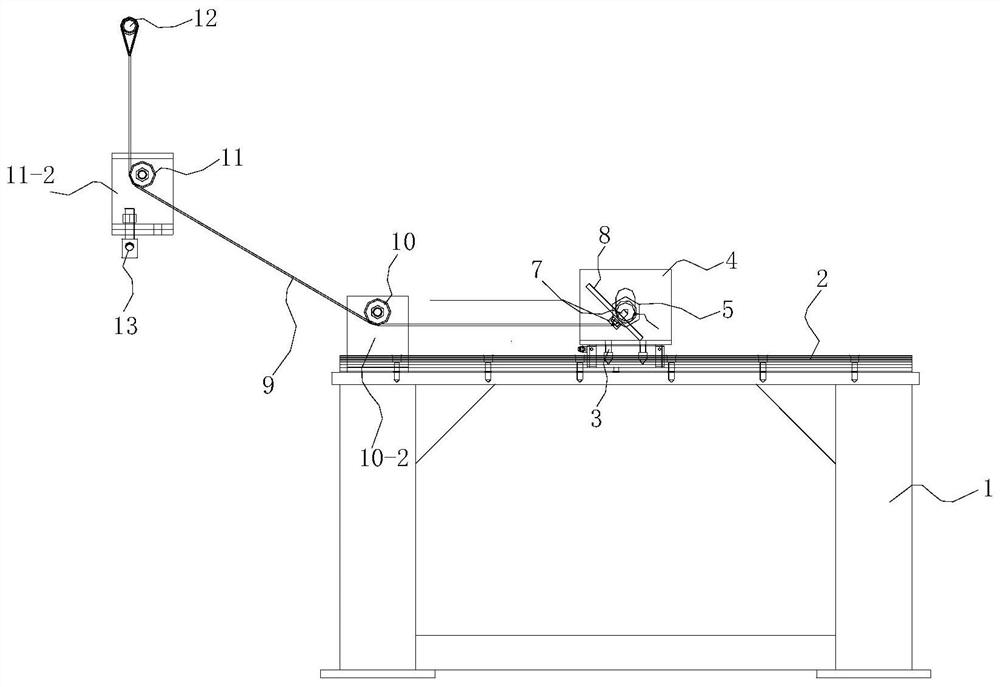

[0046] The embodiment of the present invention provides a mortar constructability test device, which is used to carry out the mortar constructability test method described in Embodiment 1.

[0047] Such as Figure 3-5 As shown, a mortar constructability test device includes a base material set on a workbench 1, a trowel 8, a limit movement device, a transmission device and a traction measurement device.

[0048] Wherein, the base material is used to set the mortar to be tested; the limit motion device includes a moving part and a fixed part, the fixed part is installed and fixed on the workbench 1, and the moving part is movably connected to the on the fixed part; the trowel is installed on the moving part, and the lower edge of the trowel faces the base material; the traction measurement device is equipped with traction control for the running speed of the traction end and The function of collecting data on the traction force-displacement relationship; the traction end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com