Method and device for detecting leakage of shell type heat exchanger

A technology of shell-and-tube heat exchanger and leakage detection device, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, which can solve the problems of high labor intensity, influence of detection results, large compressed air pressure of rubber plug, etc., and achieve The effect of reducing labor intensity, eliminating external interference, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

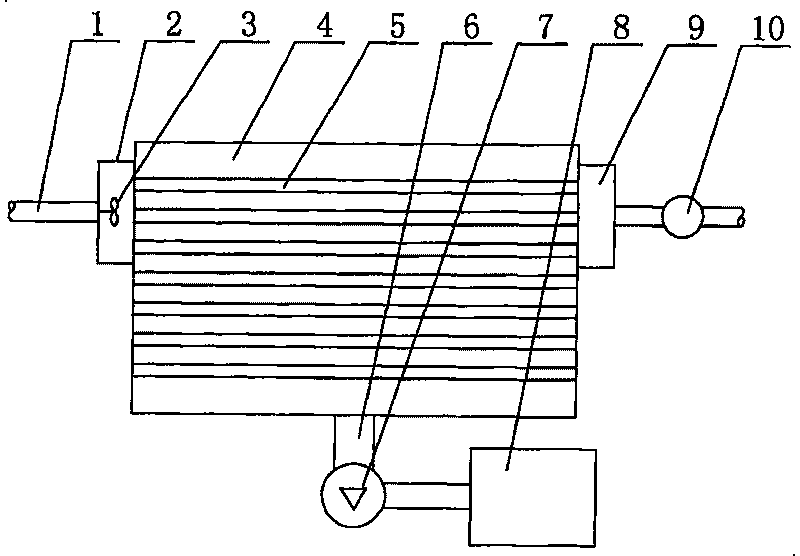

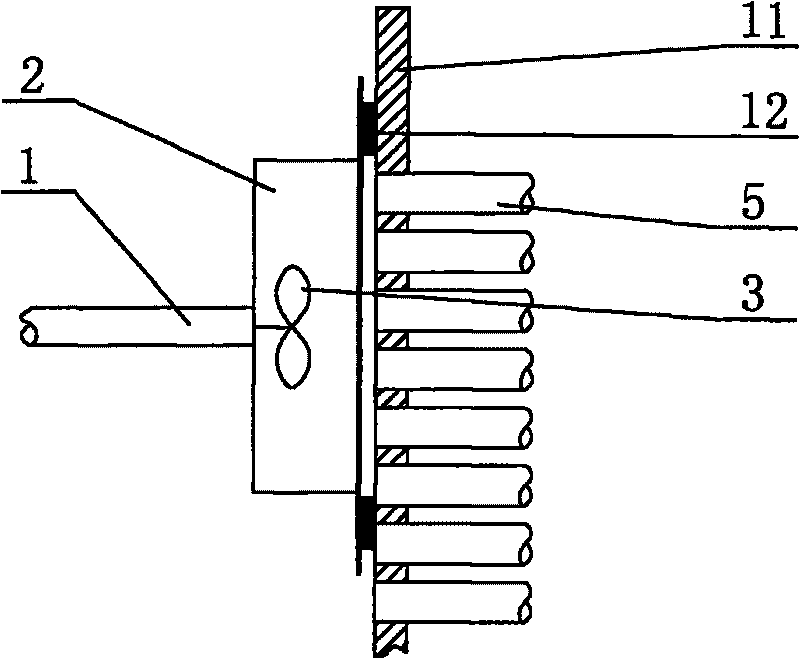

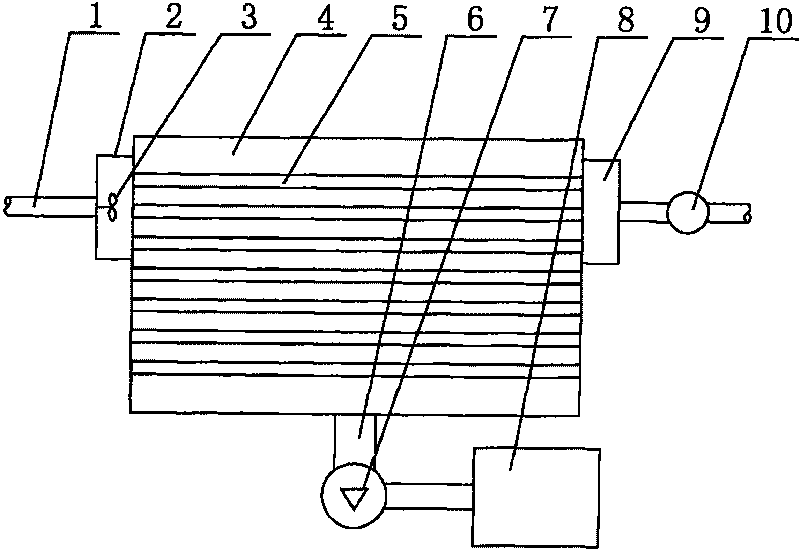

[0013] This monitoring method is to pass helium gas into the tubes of the shell-and-tube heat exchanger, use a vacuum pump connected to the shell of the shell-and-tube heat exchanger to evacuate the cavity formed by the shell and the outer wall of the tubes, and then pass the helium mass spectrometer to detect The leak meter detects the helium gas flow at the outlet of the vacuum pump to determine whether the helium tube is leaking. Specific detection devices such as figure 1 , 2 As shown, the end face of the intake cover 2 is sealed and connected with the left end sealing plate 11 of the shell-and-tube heat exchanger through a sealing strip 12, a fan 3 is installed in the intake cover, and the intake pipe 1 is installed on the intake cover; the exhaust The end face of the cover 9 is sealed and connected with the right end sealing plate of the shell-and-tube heat exchanger through a sealing strip, and an exhaust fan 10 is installed on the exhaust pipe pipe installed on the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com