Combination treatment method for combined HMBR and device

A treatment method and treatment device technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as energy waste, increase dissolved oxygen in the pool, and achieve the effect of reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

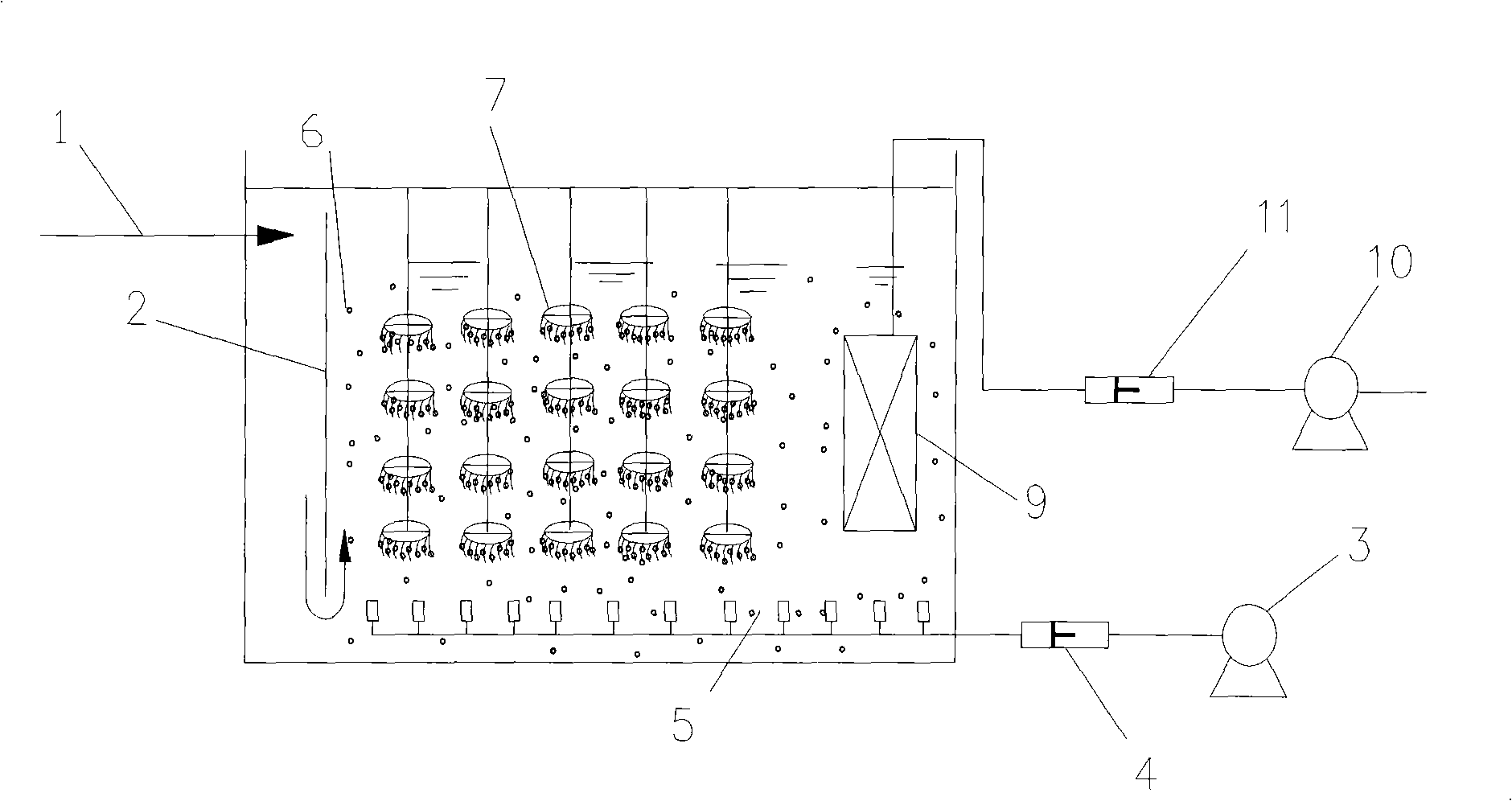

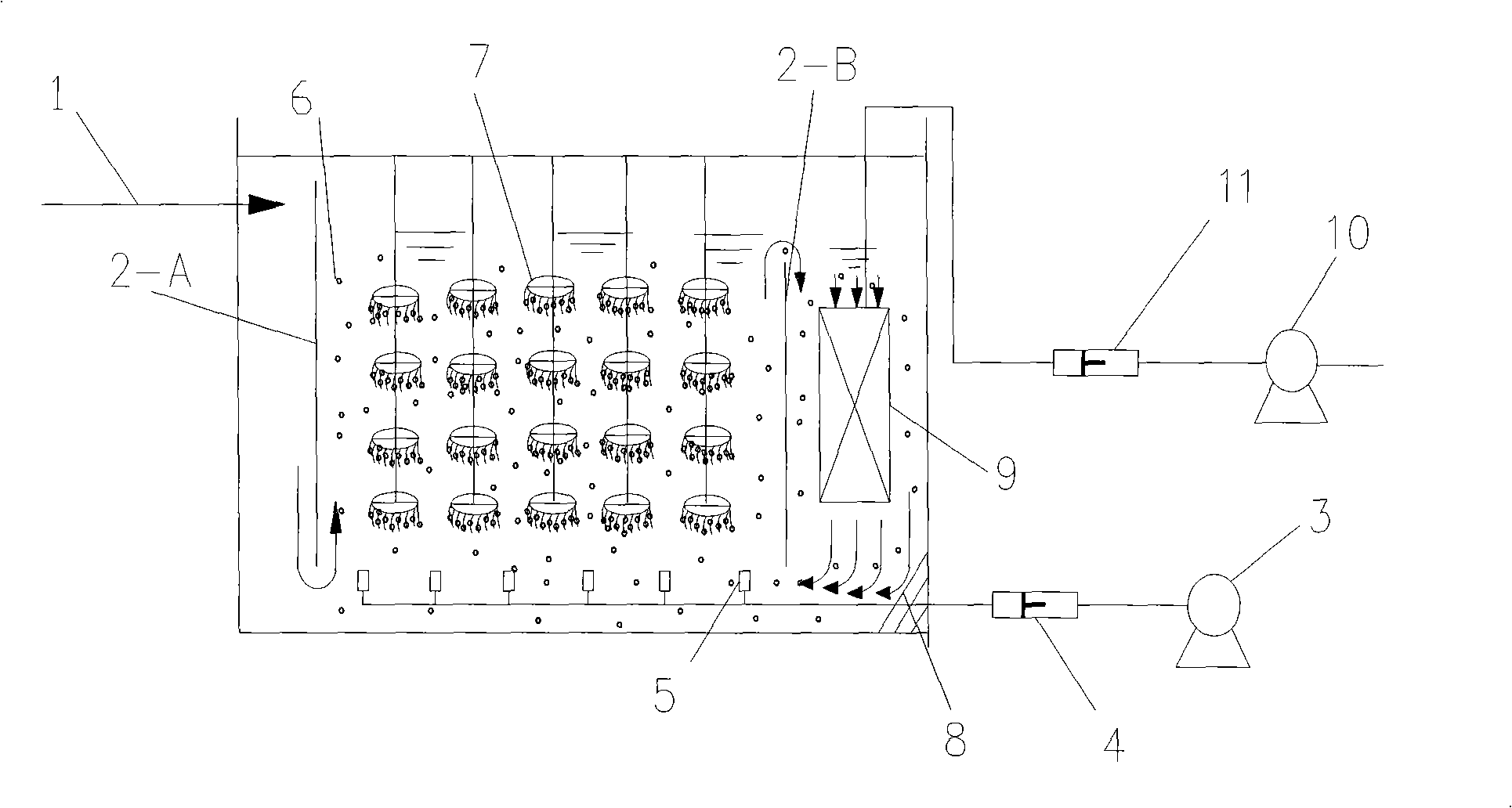

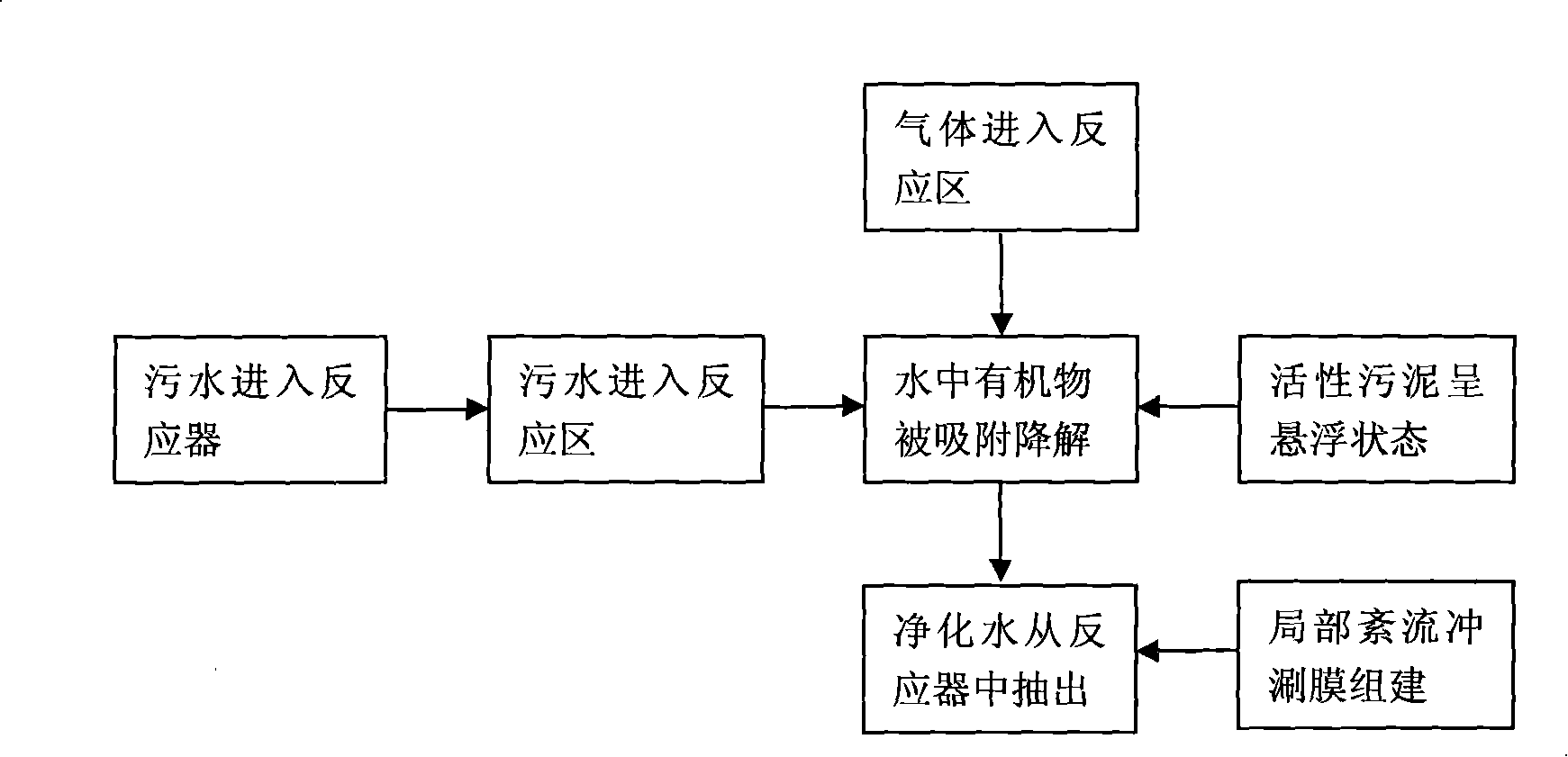

[0024] Such as figure 2 , image 3 As shown, the sewage enters the reactor from the water inlet pipe 1 and then enters the reaction zone from the bottom of the water inlet partition 2-A, and the gas enters the aerobic reaction zone from the aeration head 5 through the air pressure pump 3 under the control of the gas flow meter 4, and the activity The sludge 6 is suspended under the action of aeration, the sewage fully contacts with the activated sludge 6 in the pool and the sludge attached to the semi-soft filler 7, and the organic matter in the water is adsorbed and degraded. The local turbulent flow generated by the mud-water mixture passing through the right partition 2-B and the deflector 8 at 45° at the bottom of the pool continuously circulates in the pool to rinse the membrane assembly 9, and the purified sewage uses a peristaltic pump 10 to flow through the liquid flow meter 11 Under the control of the membrane set 9, it is withdrawn from the reactor and is treated a...

Embodiment 2

[0026] In order to reduce the energy consumption loss in the process of engineering operation and achieve the goal of "energy saving and emission reduction", the flat membrane is fixed upright in the aerobic pool according to the above-mentioned improved method, and the operation is carried out according to the above-mentioned steps. The system reduces the water output efficiency without changing the Operating costs.

Embodiment 3

[0028] In order to reduce the energy consumption loss in the process of project operation and achieve the goal of "energy saving and emission reduction", the hollow fiber membrane is fixed in the aerobic tank according to the above-mentioned improved method, and the operation is carried out according to the above-mentioned steps, the system reduces the water output efficiency without changing Operating costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com