Hydraulic wave power generation system based on volume adjusting principle

A technology of volume adjustment and power generation system, which is applied in the fields of ocean energy power generation, engine components, accumulator devices, etc. It can solve the problems of poor output energy quality, large power loss, and overall conversion efficiency reduction, and achieve energy output fluctuations. Small, improved quality, avoid power consumption and the effect of frequent pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

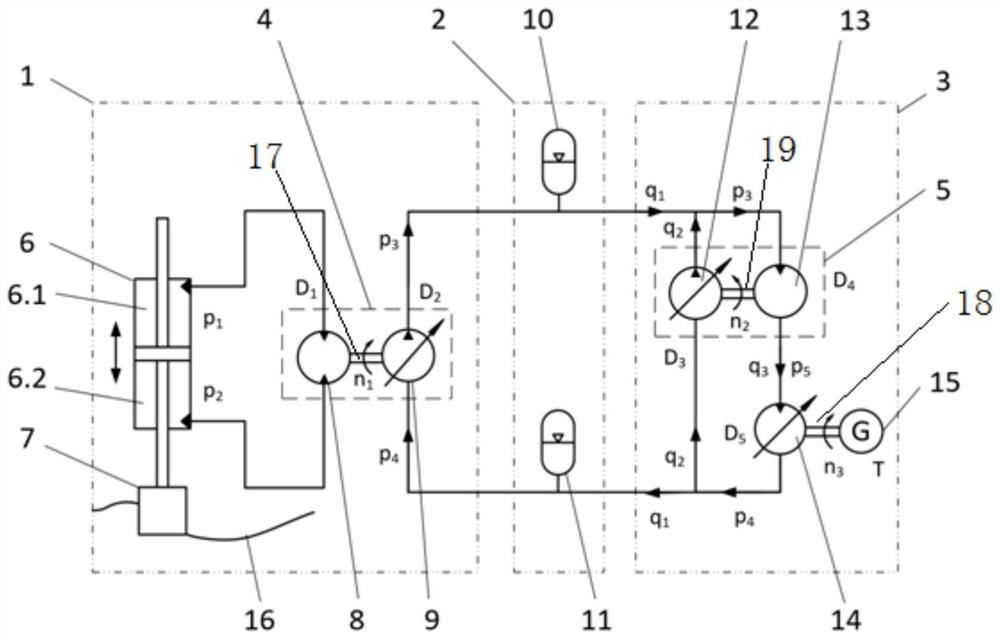

[0020] Such as figure 1 As shown, a hydraulic wave energy power generation system based on the principle of volume adjustment includes an energy capture end 1, an energy storage end 2 and an output end 3. The energy capture end 1, the energy storage end 2 and the output end 3 pass through a medium pipeline The energy harvesting terminal 1 transfers the maximum efficiency of wave energy into hydraulic energy to the energy storage terminal 2, and the energy storage terminal 2 converts the hydraulic energy with lower frequency and greater fluctuation into hydraulic energy with greater frequency and smoothness and then transfers To the output end, the output end 3 converts the stabilized hydraulic energy into electrical energy.

[0021] The energy capture end 1 includes a float 7, a hydraulic cylinder 6, and a first hydraulic transformer 4. The first hydraulic transformer 4 is composed of a bidirectional hydraulic motor 8, a first variable hydraulic pump 9 and a first coupling 17; 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com