Soot blower steam source device utilizing low-temperature reheater access port steam

A reheater and soot blower technology, applied in the field of soot blower steam source device, can solve the problems of low reheat steam parameters, economic loss of power plant, large pressure difference of regulating valve, etc., so as to improve economy and reduce maintenance cost, the effect of avoiding throttling losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

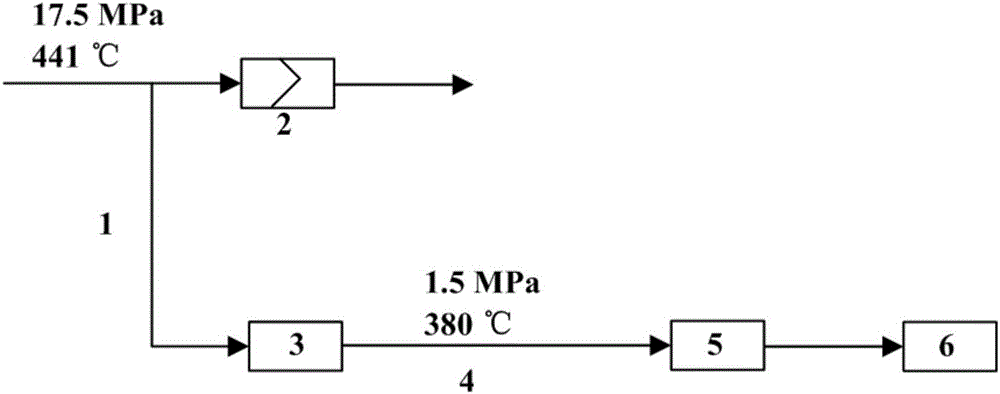

[0017] Such as figure 1 As shown, taking a subcritical 600MW unit as an example, the existing technology uses high-quality steam 1 at the inlet of the final superheater 2 as the steam source 4 for the sootblower, but the pressure and temperature parameters of the steam 1 at the inlet of the final superheater (17.5 MPa, 441°C) are very high, but the steam parameters required by the sootblower (1.5MPa, 380°C) are relatively low. According to the requirements of source 4, the steam after temperature reduction and decompression is passed into the soot blower 5, and the soot deposit on the heating surface of the boiler is removed through the soot blower 5, and the pressure difference before and after temperature reduction and decompression is as high as 16MPa. Obviously, the existing The steam source of the sootblower used in the technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com