Steering adjustment mechanism for ridge building component of paddy field ridge building machine

A technology of adjusting mechanism and ridge building machine, which is applied to agricultural machinery and implements, guiding agricultural machinery, application and other directions, can solve the problem that paddy fields with ridge building components occupy a large space, cannot build right-angled ridges, and cannot fully realize ridge building. Mechanized operation and other problems, to achieve the effect of low operation cost, low labor intensity and good quality of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

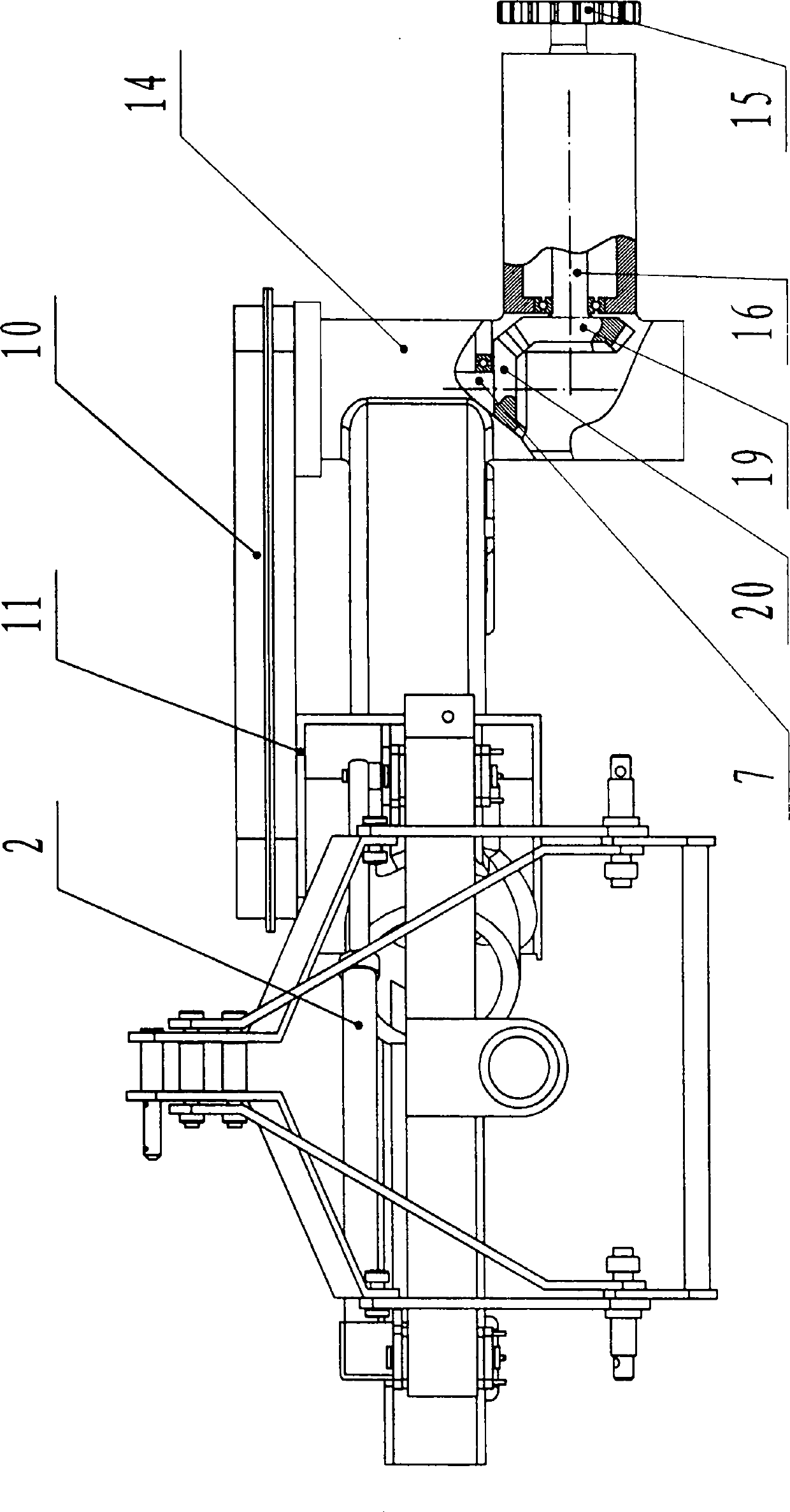

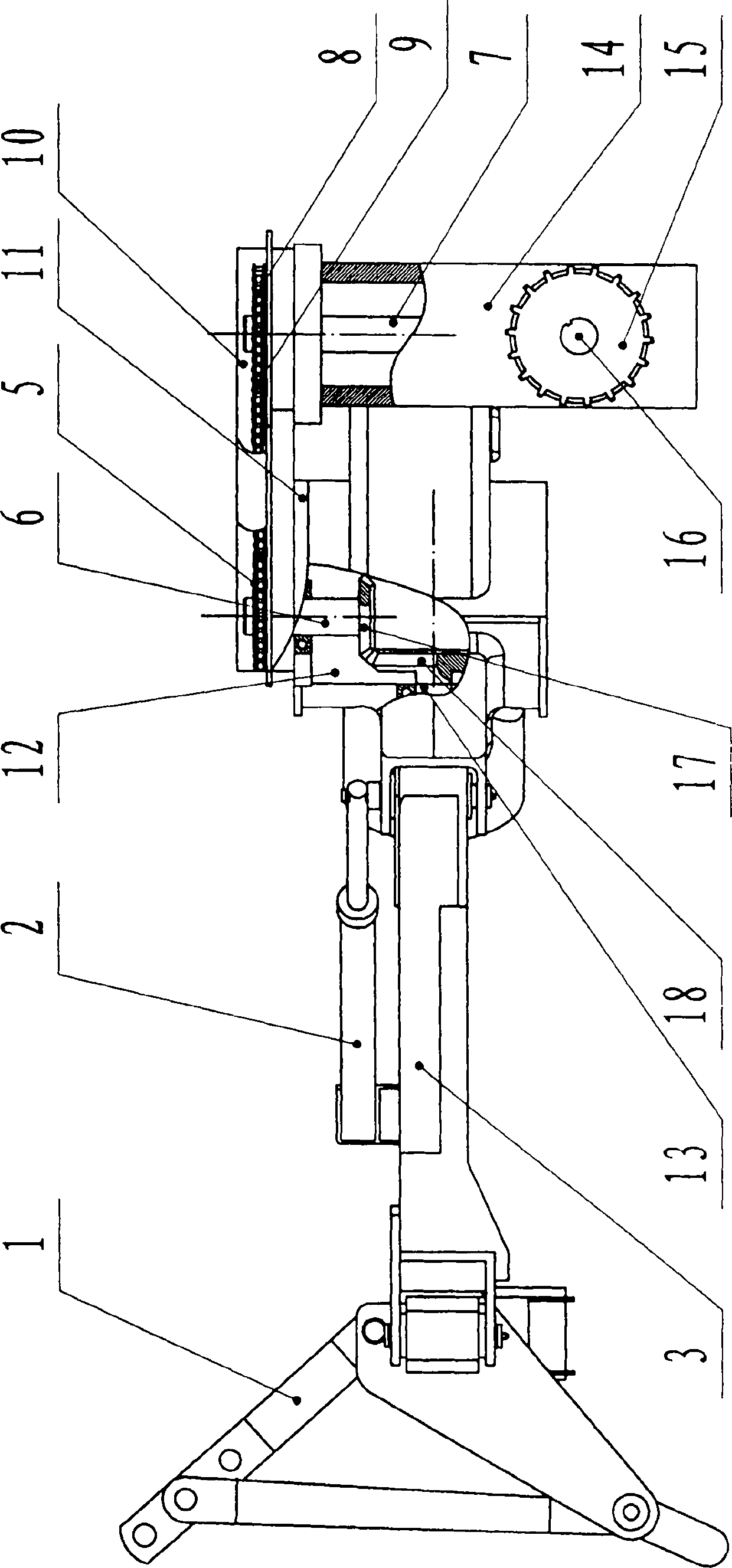

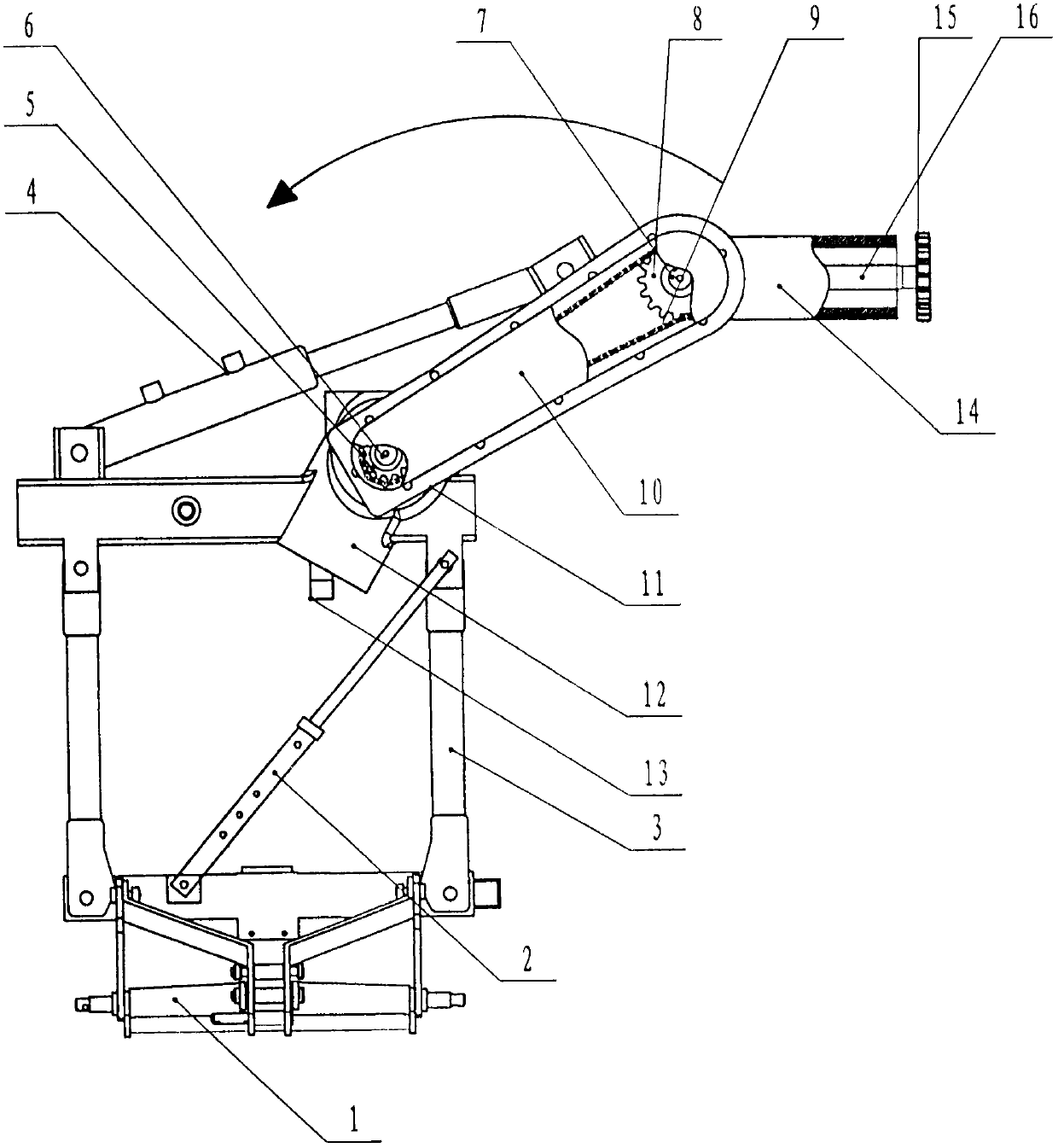

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A paddy field ridge building machine ridge building component steering adjustment mechanism includes a suspension traction frame 1 and a parallel four-bar suspension frame 3 hingedly connected, and the two ends of the horizontal parallel telescopic adjustment rod 2 are respectively hinged on the suspension traction frame 1 and the parallel four-bar suspension On the frame 3, the main transmission case 12 is fixed on the rear beam of the parallel four-bar suspension frame 3, and the rotating arm plate 11 is rotatably hinged on the upper end of the main transmission case 12. 11. The sprocket transmission box 10 is fixed on the upper end, and the power output transmission box 14 is fixed on the lower side of the outer end of the rotating arm plate 11. The two ends of the two-way hydraulic cylinder 4 are respectively hinged on the parallel four-bar suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com