Method for preparing sulfur dioxide by utilizing by-product of coking industry desulfurization system

A desulfurization system and sulfur dioxide technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of poor furnace temperature control, huge drying system, and failure to be popularized, saving investment and energy, The effect of shortening the process flow and reasonable and novel structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

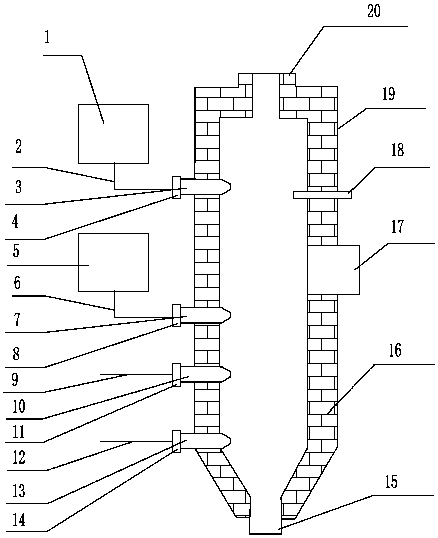

[0016] Such as figure 1 As shown, the method for preparing sulfur dioxide by using the by-products of the desulfurization system in the coking industry in this specific embodiment is: adding liquid sulfur and liquid secondary salt to the incinerator, and burning reaction with oxygen in the incinerator to generate sulfur dioxide gas; the specific method is: The liquid sulfur from the sulfur melting system 1 enters the incinerator 19 through the liquid sulfur inlet 3 through the liquid sulfur delivery pipeline 2 through the liquid sulfur flow control device 4 to adjust the flow rate, and the liquid auxiliary salt from the salt extraction system 5 passes through the liquid sulfur The auxiliary salt delivery pipeline 6 enters the incinerator 19 through the liquid auxiliary salt inlet 7 after the flow is adjusted by the liquid auxiliary salt flow control device 8, and the external oxygen entering the incinerator 19 after the flow is adjusted by the oxygen flow control device 14 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com