Gear-driven pot seedling transplantation longitudinal seedling feeding mechanism

A gear-driven and seedling-feeding technology, which is applied in the direction of transplanting machinery, belts/chains/gears, mechanical equipment, etc., can solve problems such as short service life, poor work reliability, and reduced transplanting quality, and achieve novel and reasonable structural design. Avoiding unstable transmission and fewer operational failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

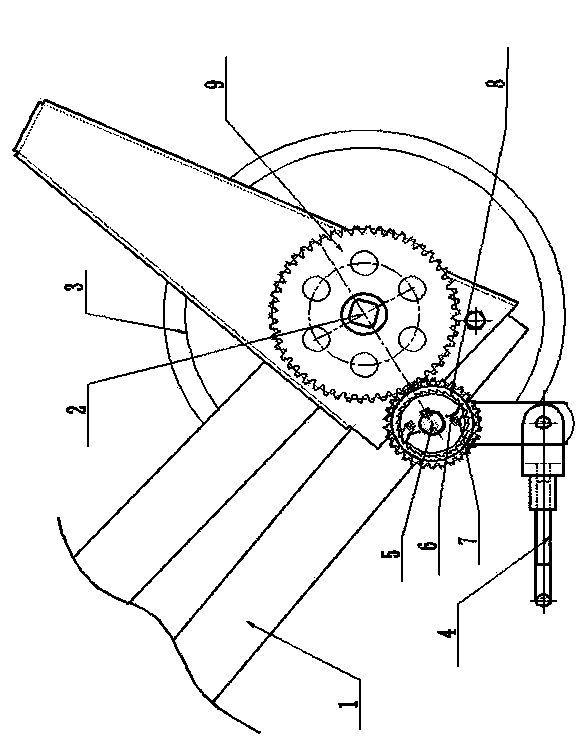

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A gear-driven pot seedling transplanting longitudinal seedling delivery mechanism includes a seedling box side bracket 1 and a seedling delivery shaft 2 fitted on the seedling box side bracket 1. The seedling delivery shaft 2 is fixed on the inside of the seedling box side bracket 1 The seedling sending wheel 3 is installed, on the seedling sending shaft 2, the seedling sending shaft drive gear 9 is fixed on the outside of the seedling box side support 1, and on the seedling box side support 1, it is rotatably equipped under the side of the seedling sending shaft 2. Install the arm shaft welding 5, the internal ratchet and the external gear assembly 8 are rotatably installed on the arm shaft welding 5, the ratchet 6 and the spring leaf 7 are fixed on the arm shaft welding 5, and the ratchet Claw 6 and the internal ratchet tooth of internal ratchet and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com