Multi-functional weed and loose soil machine

A weeding and loosening machine, multi-functional technology, applied in the direction of soil preparation machinery, agricultural machinery and implements, applications, etc., can solve the problems of reducing crop yield, reducing operation quality, affecting the growth and development of crop roots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

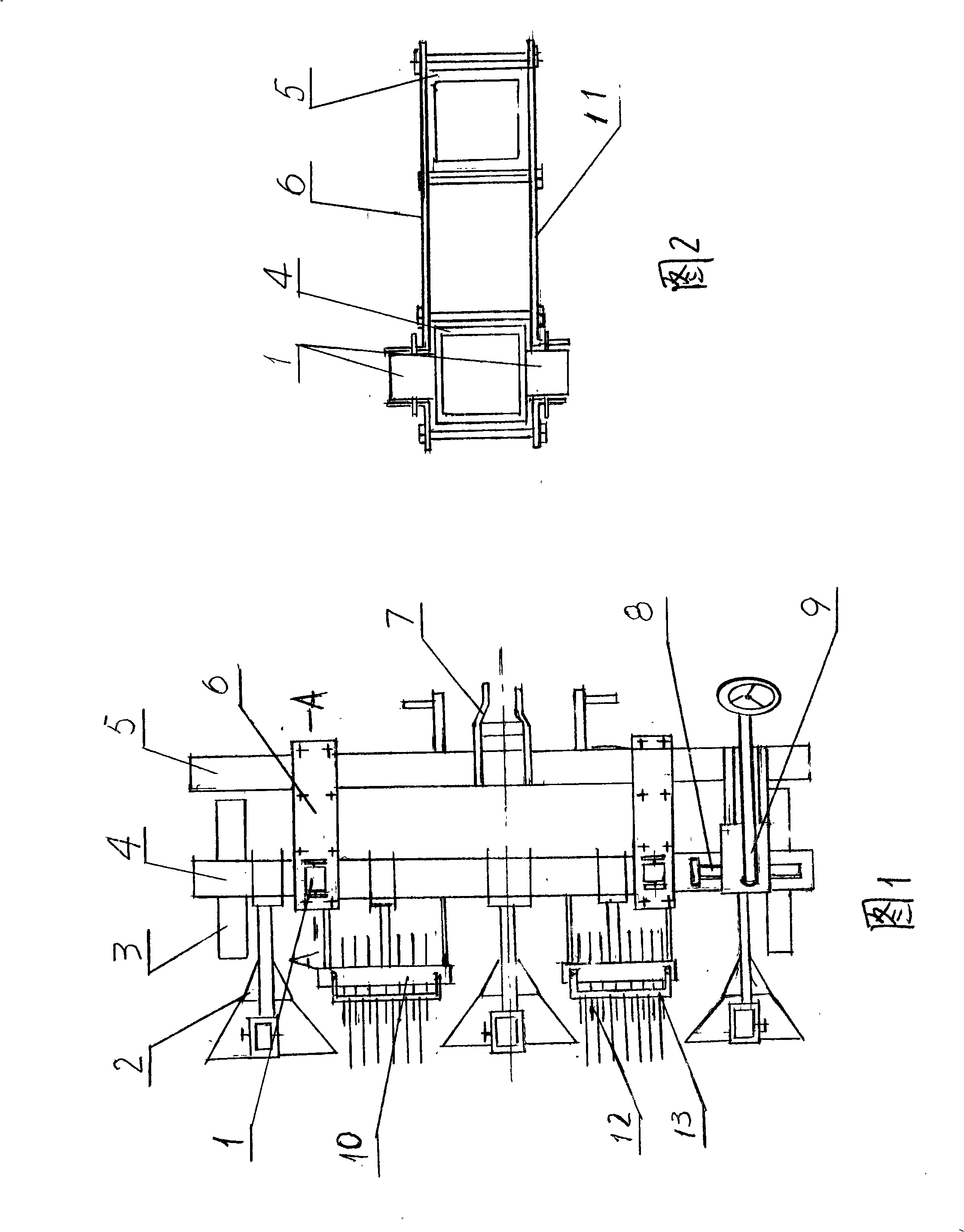

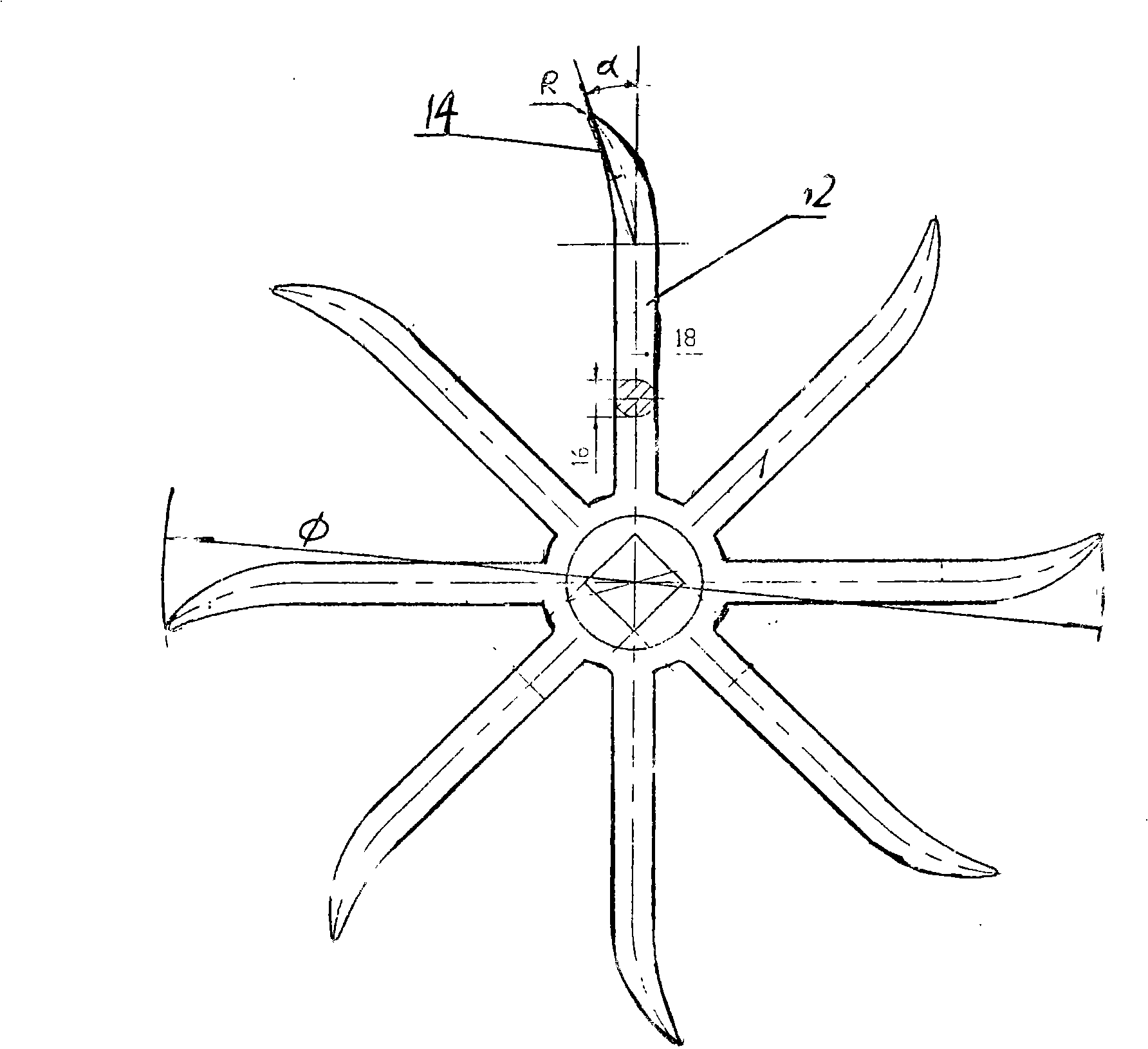

[0011] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. The multi-functional weeding and loosening machine includes ground wheels 3, suspension frame assembly 7 and weeder assembly 10, and upper and lower fixed connection plates are fixedly installed on the upper and lower planes of the left and right sides of the front beam 5 6 and the lower fixed connecting plate 11, the rollers 1 are respectively installed on the upper fixed connecting plate 6 and the lower fixed connecting plate 11, and the rear beam 4 can be inserted between the upper fixed connecting plate 6 and the lower fixed connecting plate 11 so as to move left and right position, the cylindrical outer surface of the roller 1 on the upper fixed connecting plate 6 is in contact with the upper plane of the rear beam 4, and the outer surface of the roller 1 cylinder on the lower fixed connecting plate 11 is in contact with the lower plane of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com