Feed processing system and processing technology

A feed processing and processing technology, applied in the fields of feed, food science, application, etc., can solve the problems of affecting product quality, many impurities, costing manpower and funds, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

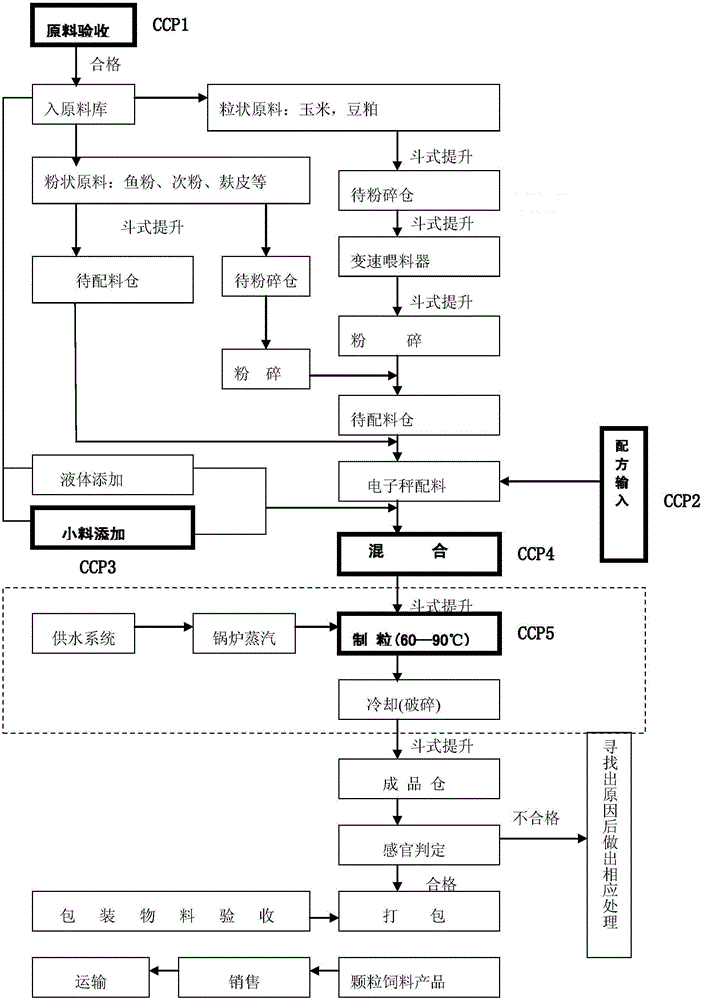

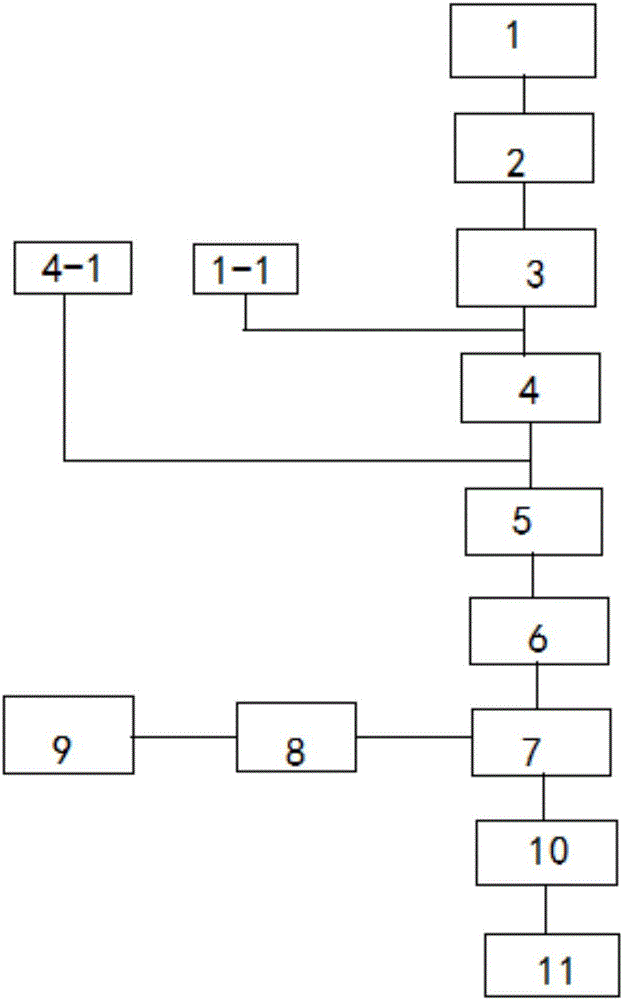

[0012] Such as Figure 1-2 As shown, this specific embodiment adopts the following technical scheme: it includes a bin to be crushed 1, a variable speed feeder 2, a pulverizer 3, a bin to be batched 4, an electronic scale batching device 5, a mixing device 6, a granulating mechanism 7, a boiler Steam device 8, water supply system 9, cooling device 10, finished product bin 11, second bin to be crushed 1-1 and second bin to be batched 4-1, bin to be crushed 1, variable speed feeder 2, and pulverizer 3 are connected in sequence , the second bin 1-1 to be pulverized is connected to the pulverizer 3 and connected to the bin 4 to be batched, the bin 4 to be batched is connected to the electronic scale batching device 5, and the second bin 4-1 to be batched is connected to the bin 4 to be batched, The electronic scale batching device 5, the mixing device 6, and the granulating mechanism 7 are connected sequentially. The water supply system 9 is connected to the boiler steam device 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com