Liquid fertilizer hole prickling and injecting mechanism

A chemical fertilizer and liquid technology, applied in direct liquid fertilizer delivery system, planting method, excavation/covering ditches, etc., can solve the problems of increasing machine weight and cost, low fertilizer utilization rate, and low environmental pollution of fertilizer utilization rate, etc. Achieve the effect of novel and reasonable structural design, compact overall size and good working quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

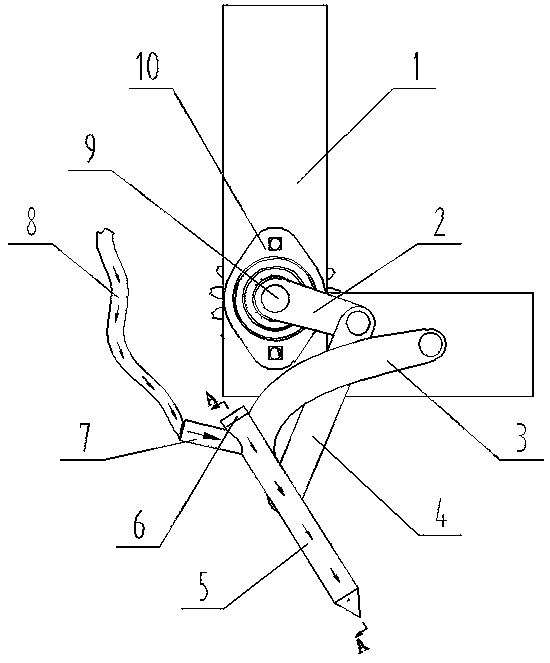

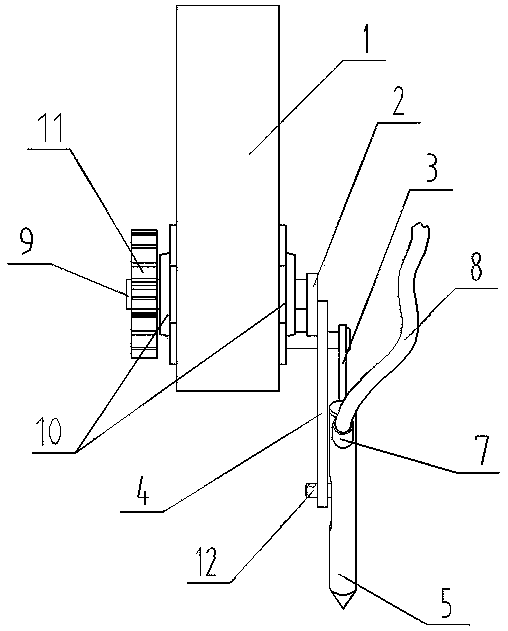

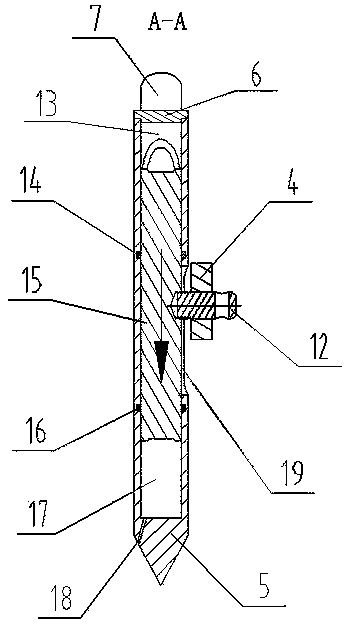

[0014] Attached below figure 1 , attached figure 2 , attached image 3 and attached Figure 4 Describe in detail the embodiments of the present invention:

[0015] A liquid chemical fertilizer burrowing and injecting mechanism, a bearing seat 10 is respectively fixed on the front and rear sides of the mounting frame 1, a transmission shaft 9 is rotatably inserted in the bearing seat 10, and one end of the transmission shaft 9 is fixed on one side. The drive gear 11 is installed, the rocker arm 2 is fixed on the other end of the transmission shaft 9, the upper end of the fertilizing needle housing 5 is fixed with the plug 6, and the second one-way valve 15 can be moved axially and is assembled on the fertilizing needle. In the cavity of the housing 5, the upper side and the lower side of the cavity of the fertilizing needle housing 5 are respectively provided with a fertilizer storage cavity 13 and a fertilizer discharge cavity 17, and the upper end of the second one-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com