Grid automatic stacking device

A driving device and grid technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of physical injury to workers, low work efficiency, high labor intensity, etc., and achieve the advantages of reducing labor intensity, convenient operation and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

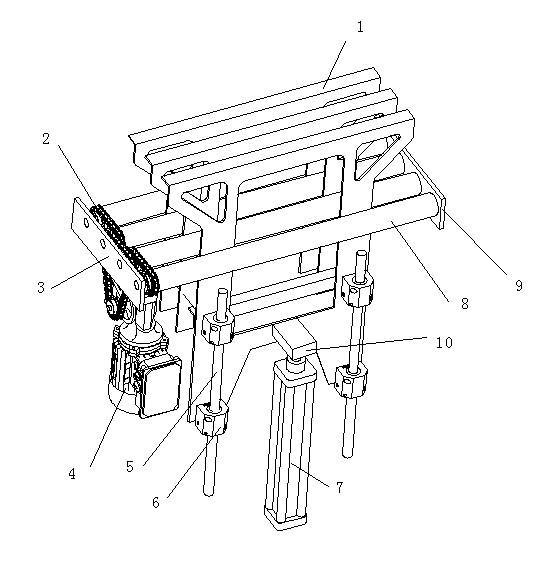

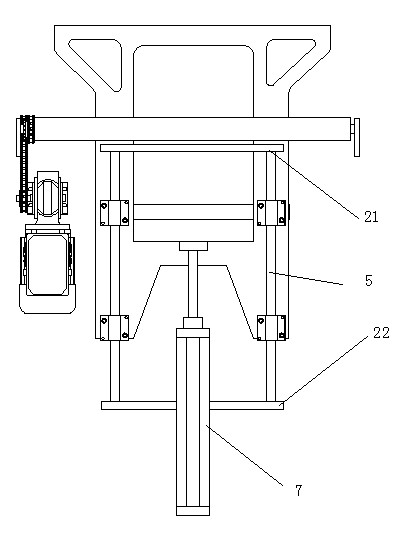

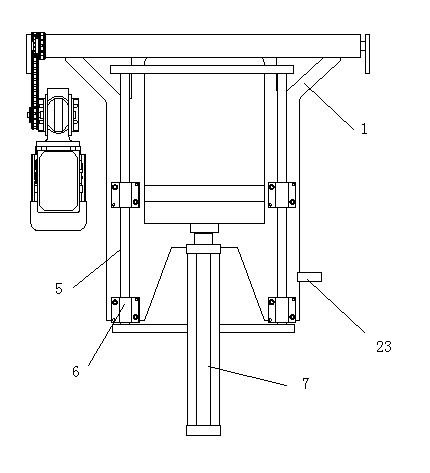

[0016] Such as figure 1 , 6 As shown, the grid automatic stacking device in the present invention includes: a frame 100, a stacking mechanism, a conveying mechanism, a control device and a grid detection device. The stacking mechanism and the conveying mechanism are arranged on the frame. The frame 100 may be a frame of other grid processing devices, or may be an independent frame of the automatic grid stacking device itself.

[0017] Such as figure 1 , 2 , 4, the stacking mechanism includes a support frame, a guide mechanism and a driving device for the grid support frame. The support frame includes several pieces of upside-down "L" or "T" brackets 1 with a set width at the top, and each bracket 1 is fixedly connected together by a connecting plate 11 arranged at its lower end. The upper part of the bracket 1 can extend upwards through the conveyor roller 8 through the gap between the conveyor rollers 8, and the top ends of each bracket 1 together form a support plane fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com