Full-automatic laser marking device for engine cylinder ring

An engine cylinder and laser marking technology, which is applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve problems affecting production efficiency and increasing human resource input costs, and achieve simple structure, solve human resource input, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Specific embodiments of the present invention will be described below.

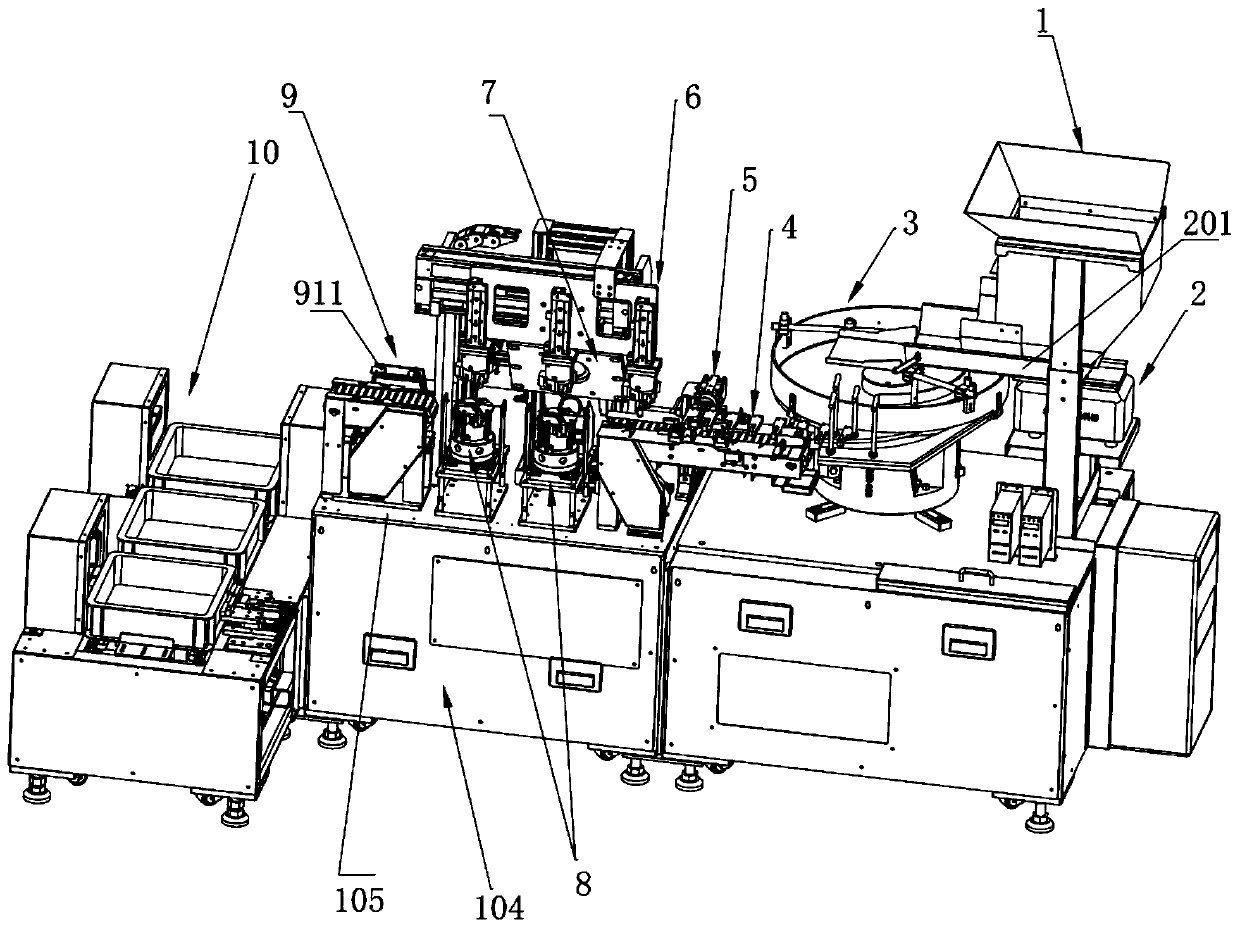

[0068] Such as figure 1 , figure 2 As shown, the fully automatic laser marking device for the cylinder ring of the engine is composed of a feeding mechanism, an executing mechanism and a feeding mechanism 10 arranged in sequence;

[0069] Such as Figure 1 to Figure 5 As shown, the feeding mechanism includes a first welding frame 101 with an electric control cabinet 102, a first worktable 103 is arranged on the first welding frame 101, and a vibrating feeder is arranged on the first worktable 103 2. The discharge tray 201 is arranged on the surface of the vibrating feeder 2, the feed end of the discharge tray 201 is docked with the discharge port of the hopper 1, and the discharge end of the discharge tray 201 is docked with the disc body of the vibration plate 3;

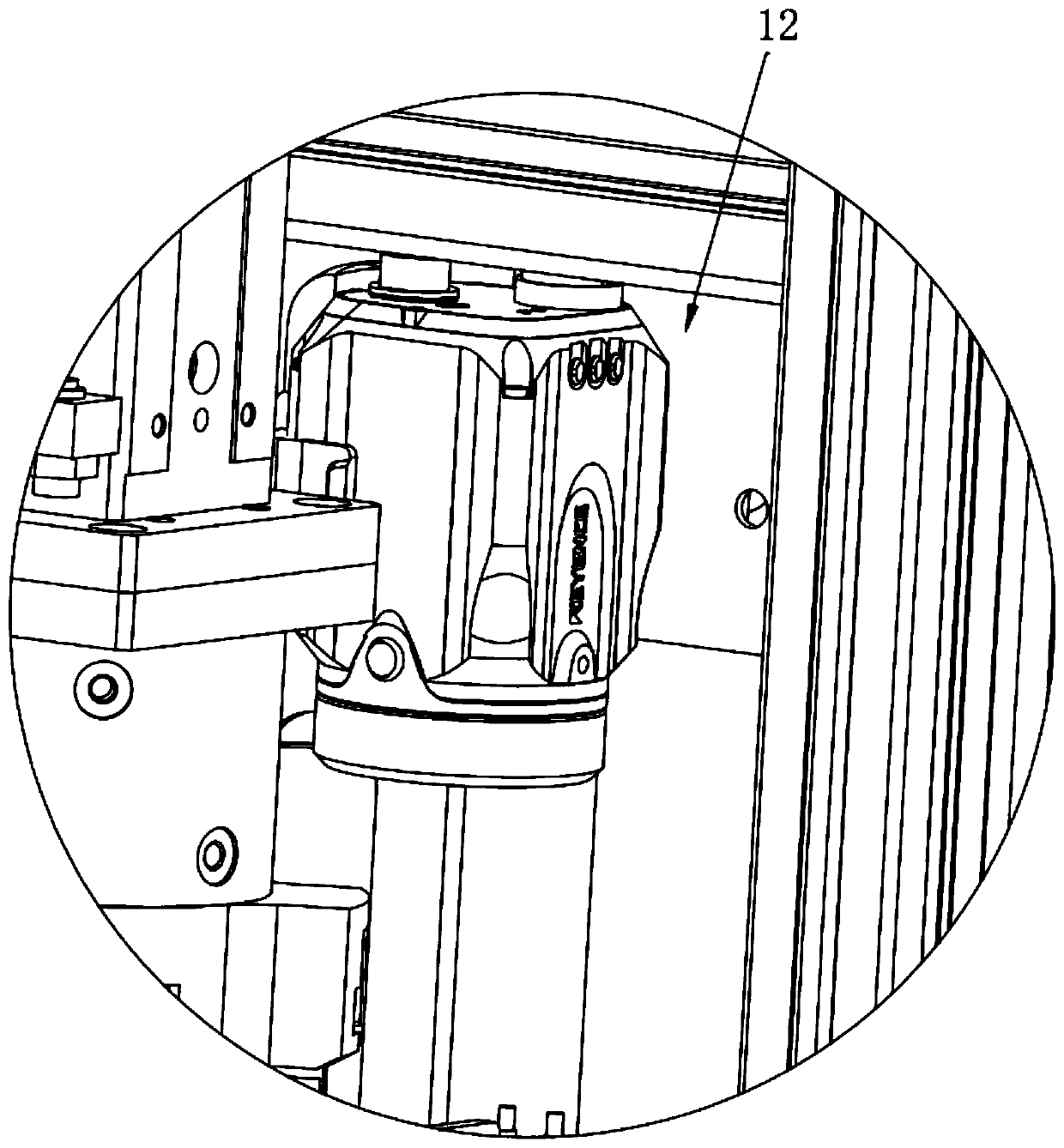

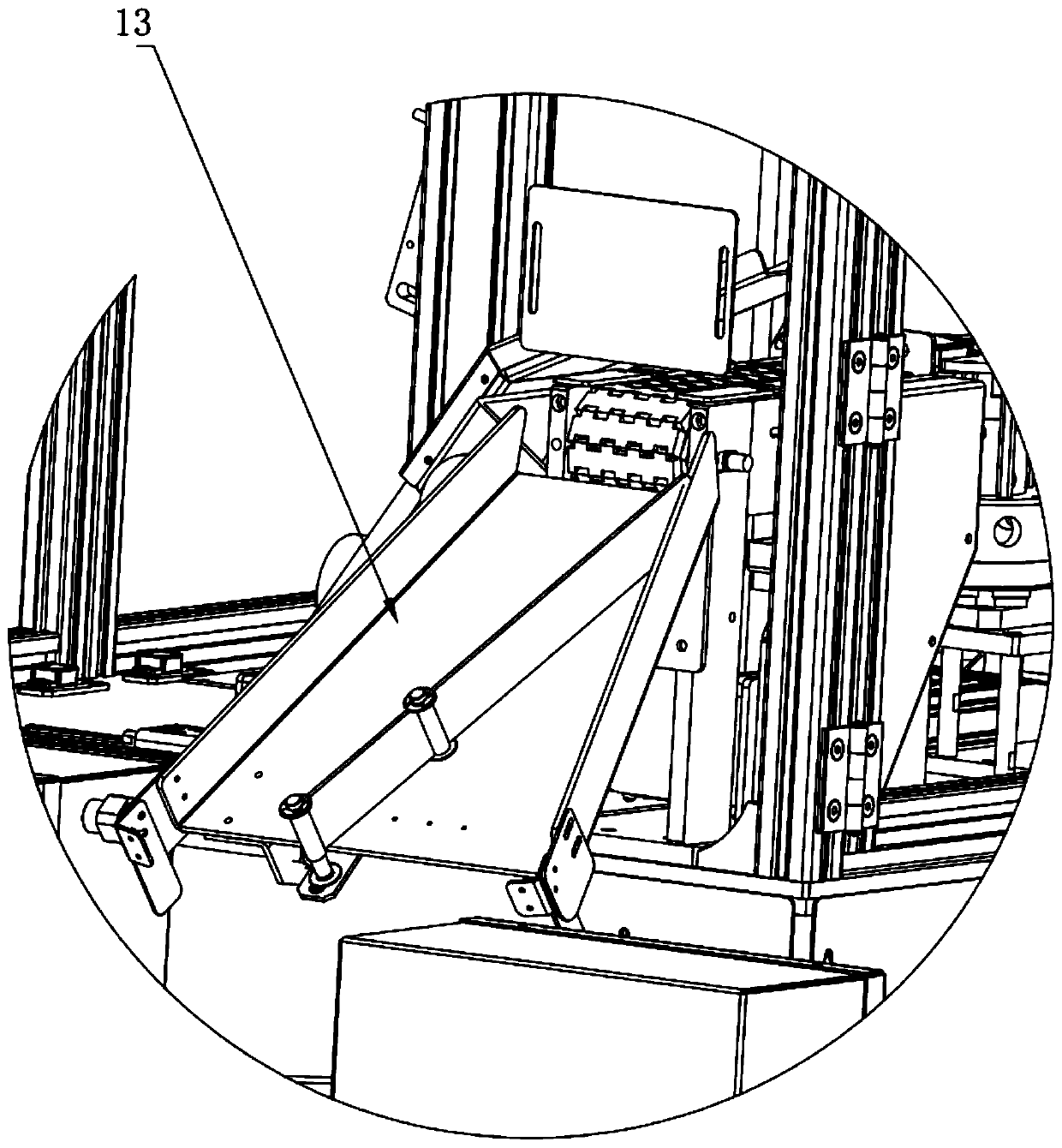

[0070] The executive mechanism includes a second welding frame 104 and a cover assembly 11. A second worktable 105 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com