Sheet counter and working method thereof

A technology of counting machine and rack, which is used in packaging automatic control, liquid materials, paper product packaging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

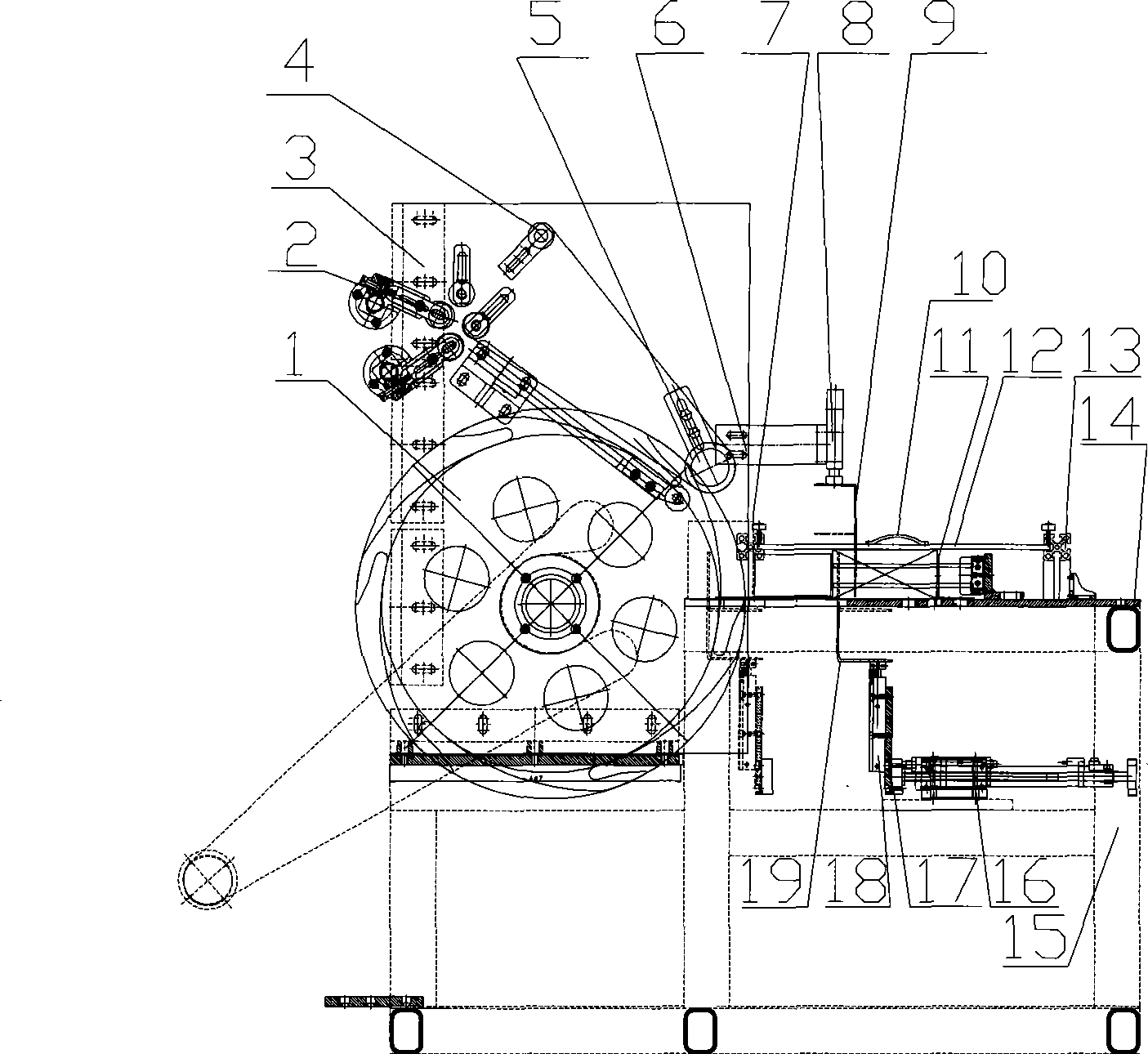

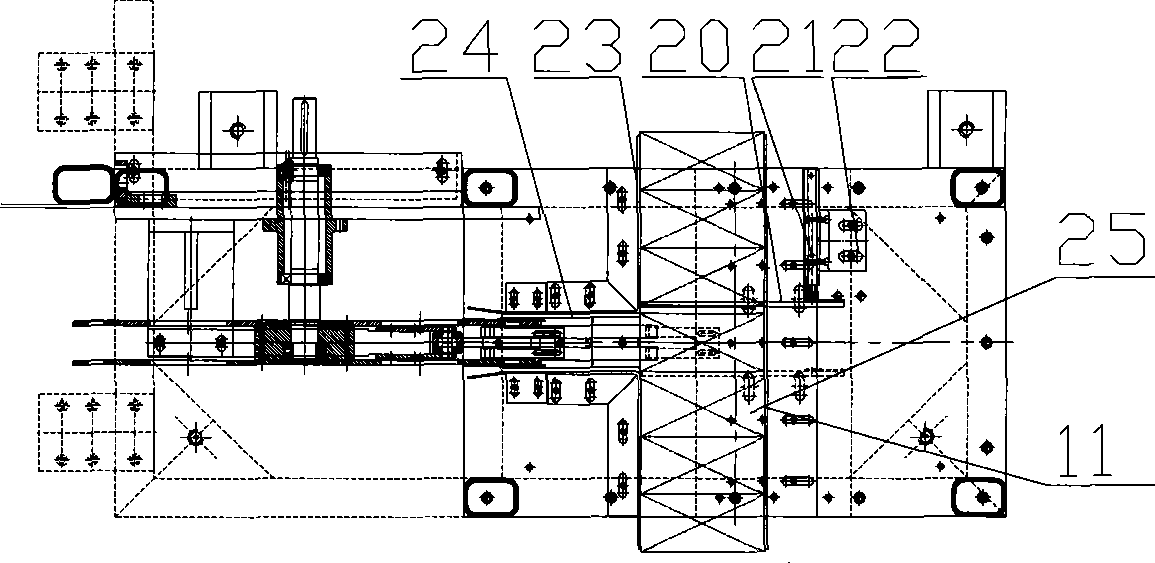

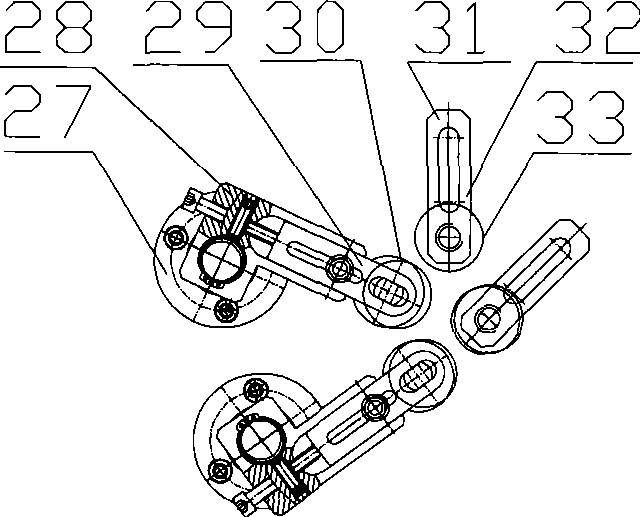

Embodiment 1

[0011] Embodiment 1: with reference to attached Figure 1~3 . On the sheet counting machine, a photoelectric sensor is arranged above the front of the wheel fork 1, which is mainly used to detect the number of sheets passed by the sanitary napkin. The signal of the photoelectric sensor is transmitted to the controller (PLC) and the amount of counting is set by the controller. The wheel fork 1 is socketed with the shaft on the frame wallboard 3 and is rotatable. The pulley adjustment mechanism 2 is composed of two pulley adjustment seats 28, two guide wheel shafts 27 with flanges, two guide pulleys 30, 4 guide pulley positioning frames 29, two tension pulley adjustment fixing mounts 31, two tension pulleys. Tightening wheel shaft 32 and two tensioning pulleys 33 constitute, two guide wheel shafts 27 with flanges are vertically spaced and fixed on the frame wallboard 3, two belt pulley adjustment seats 28 rear parts have shaft holes and are fixed on the On the guide wheel shaf...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the surface of the longitudinal channel 24 has a fork-shaped structure, that is, the middle is an insertion rod, and the two sides of the insertion rod are open long holes. The forked faces of the channels 24 cooperate.

Embodiment 3

[0013] Embodiment 3: On the basis of Embodiments 1 and 2, the working method of the chip counting machine, the wheel fork 1 drives the sanitary napkin in the wheel fork to rotate, when the sanitary napkin rotates and passes through the photoelectric sensor located above the front of the wheel fork 1 After the photoelectric sensor collects a data and the wheel fork 1 drives the sanitary napkin to rotate to the end face of the longitudinal channel 24, the sanitary napkin located in the wheel fork 1 is guided into the longitudinal channel 24 by the fork rod in the longitudinal channel 24, when the sanitary napkin in the longitudinal channel 24 When the quantity reaches the set quantity, the controller instructs the piston in the double cylinder 18 connected to the handle 19 to extend, and the piston in the guide rod cylinder 16 connected to the double cylinder 18 to retract and drive the double cylinder 18 and the handle 19 is retracted, and the handle 19 drives several pieces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com