Corrugated paperboard stacking device

A technology of stacking device and corrugated cardboard, which is applied in the direction of stacking receiving device, transportation and packaging, sending objects, etc., which can solve the problems of unfavorable production work, heavy stacking work, and increased labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the embodiments of the present invention will be described below with reference to the accompanying drawings.

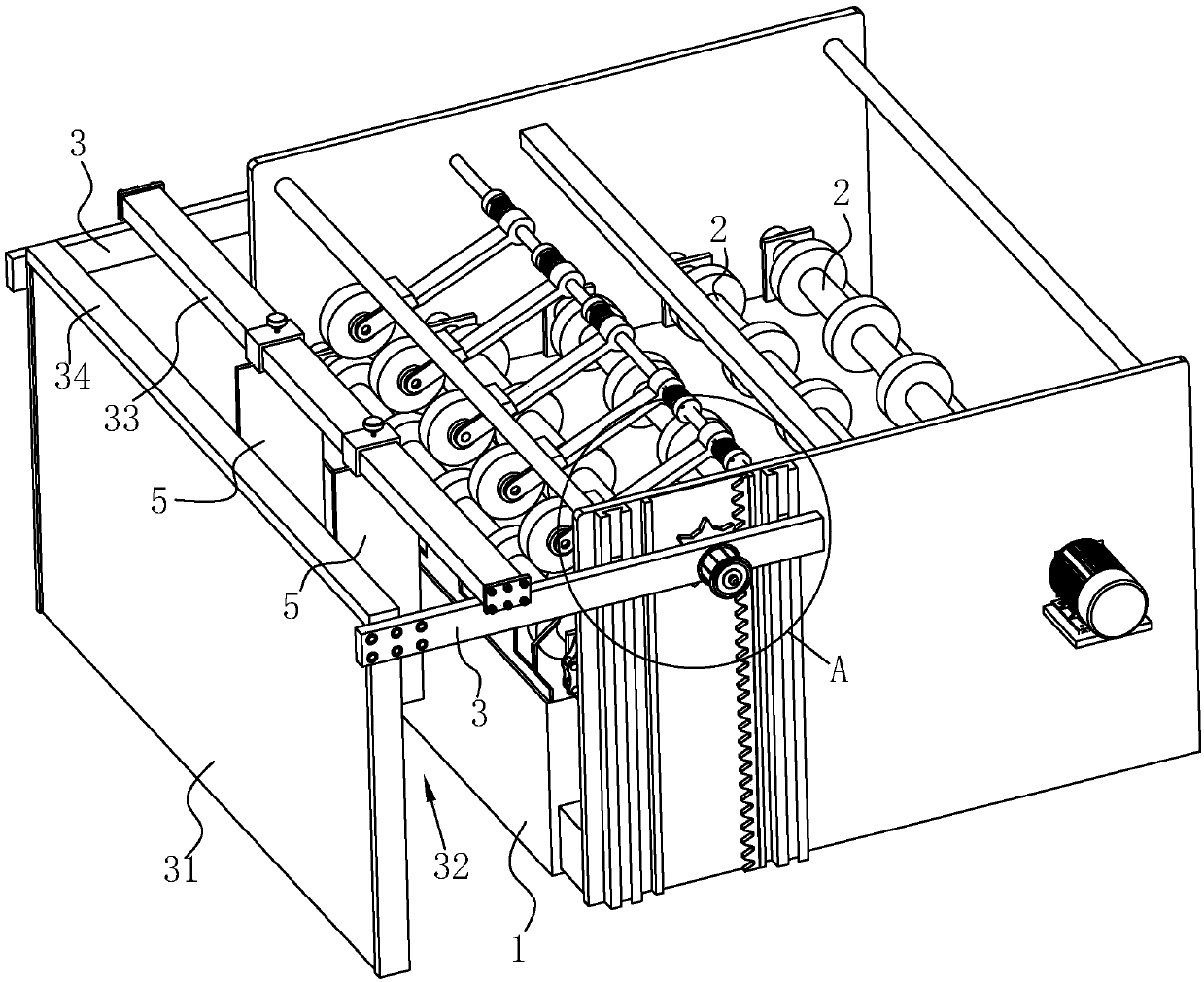

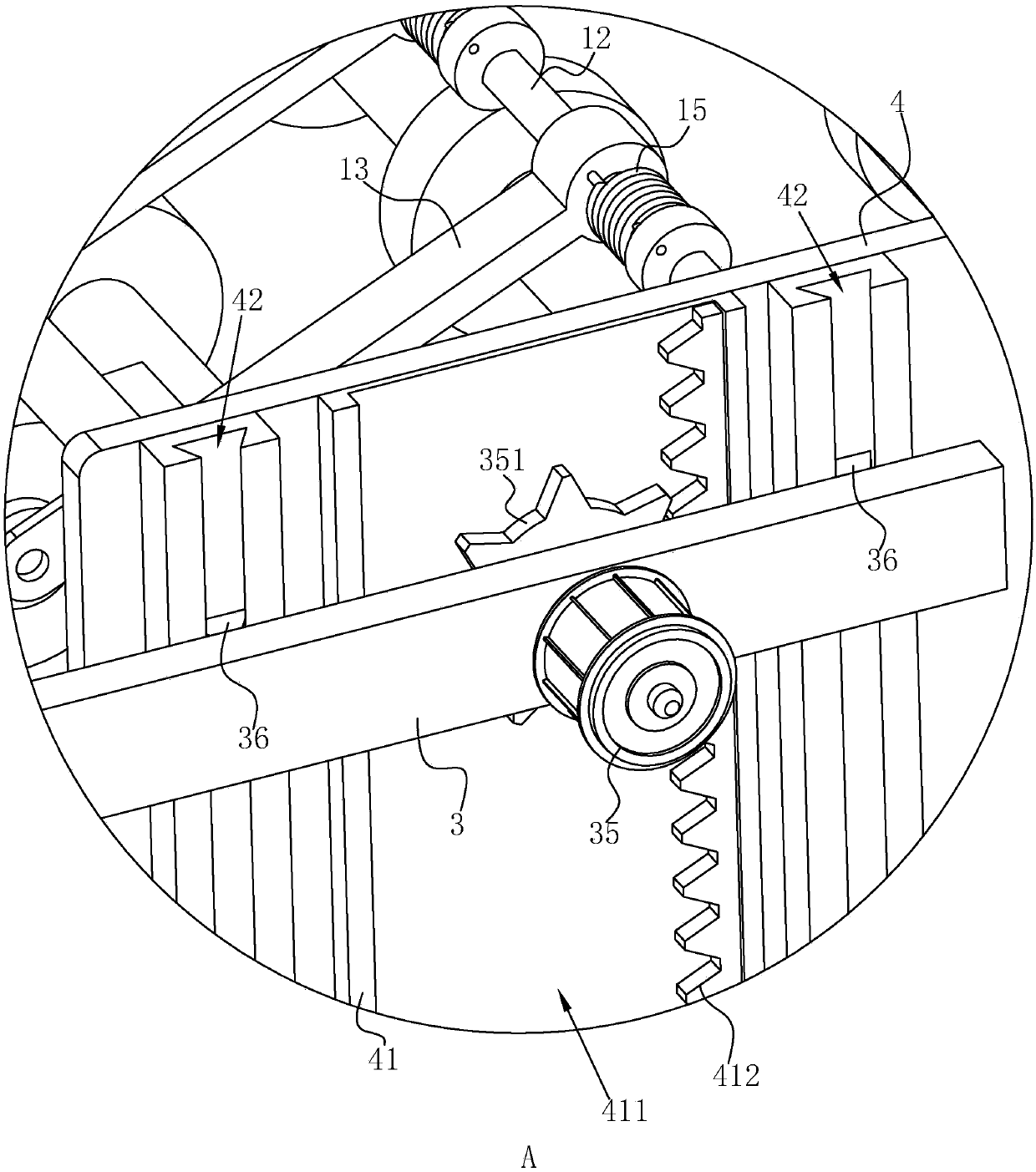

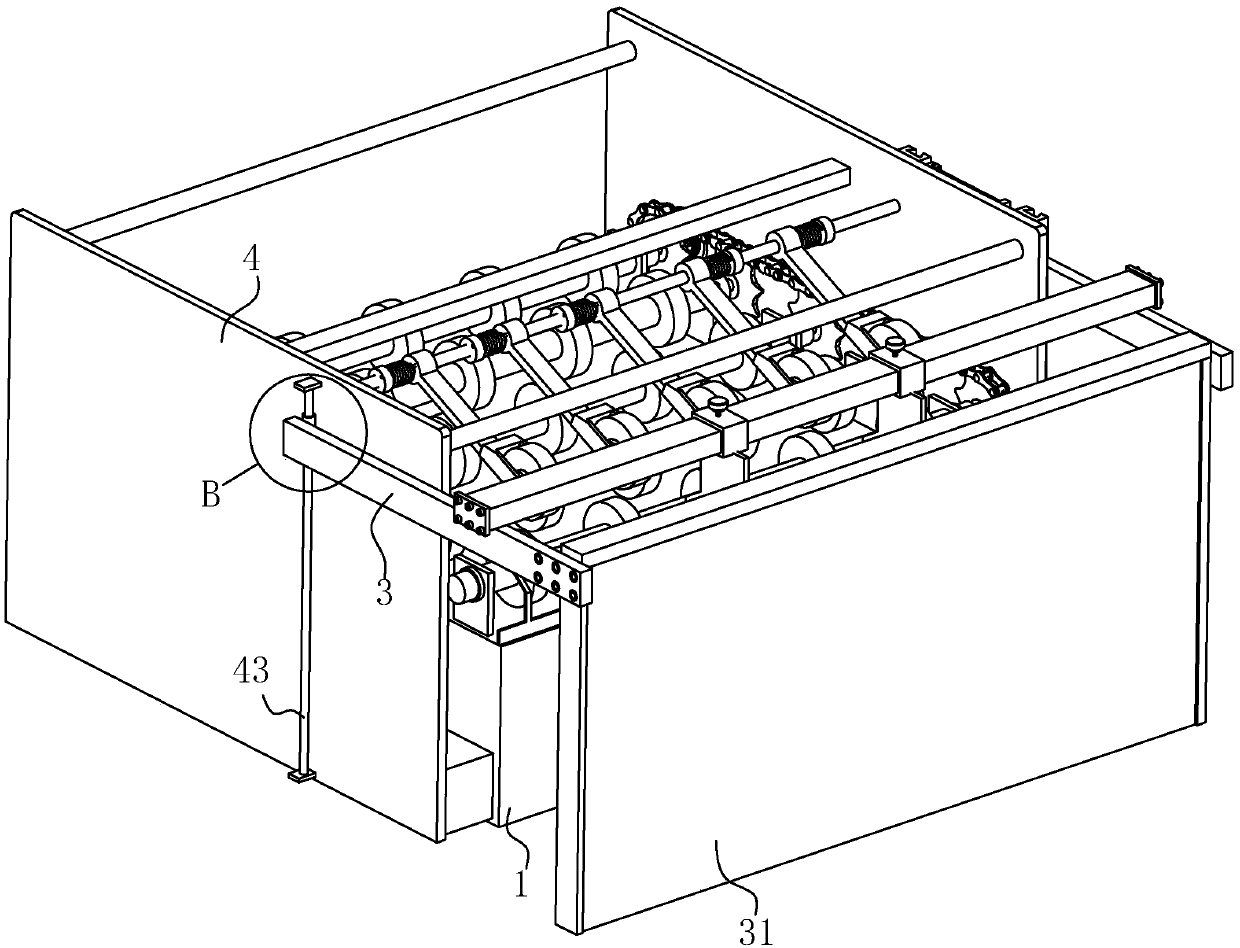

[0036] Such as figure 1 , 5As shown, a corrugated cardboard stacking device includes a frame 1 and a conveying device arranged on the frame 1. The conveying device includes a plurality of rotating shafts 2 arranged on the frame 1, and the plurality of rotating shafts 2 are evenly distributed. And arranged on the frame 1, the rotating shaft 2 is arranged with a plurality of rubber rings 23 along the length direction of the rotating shaft 2, and the surface of the rubber ring 23 conflicts with the surface of the corrugated paper; Therefore, the corrugated paper on the rubber ring 23 is not easy to slip on the rubber ring 23 during the conveying process, so that the corrugated paper can be conveyed relatively smoothly. The frame 1 is provided with a driving assembly, which can simultaneously drive a plurality of rotating shafts 2 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com