Discharging mechanism for full-automatic laser marking device

A laser marking and fully automatic technology, applied in auxiliary devices, laser welding equipment, conveyors, etc., can solve the problems of increasing human resource input costs, increasing labor intensity of workers, and reducing enterprise production efficiency, so as to save human resource investment, The structure is simple and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described below.

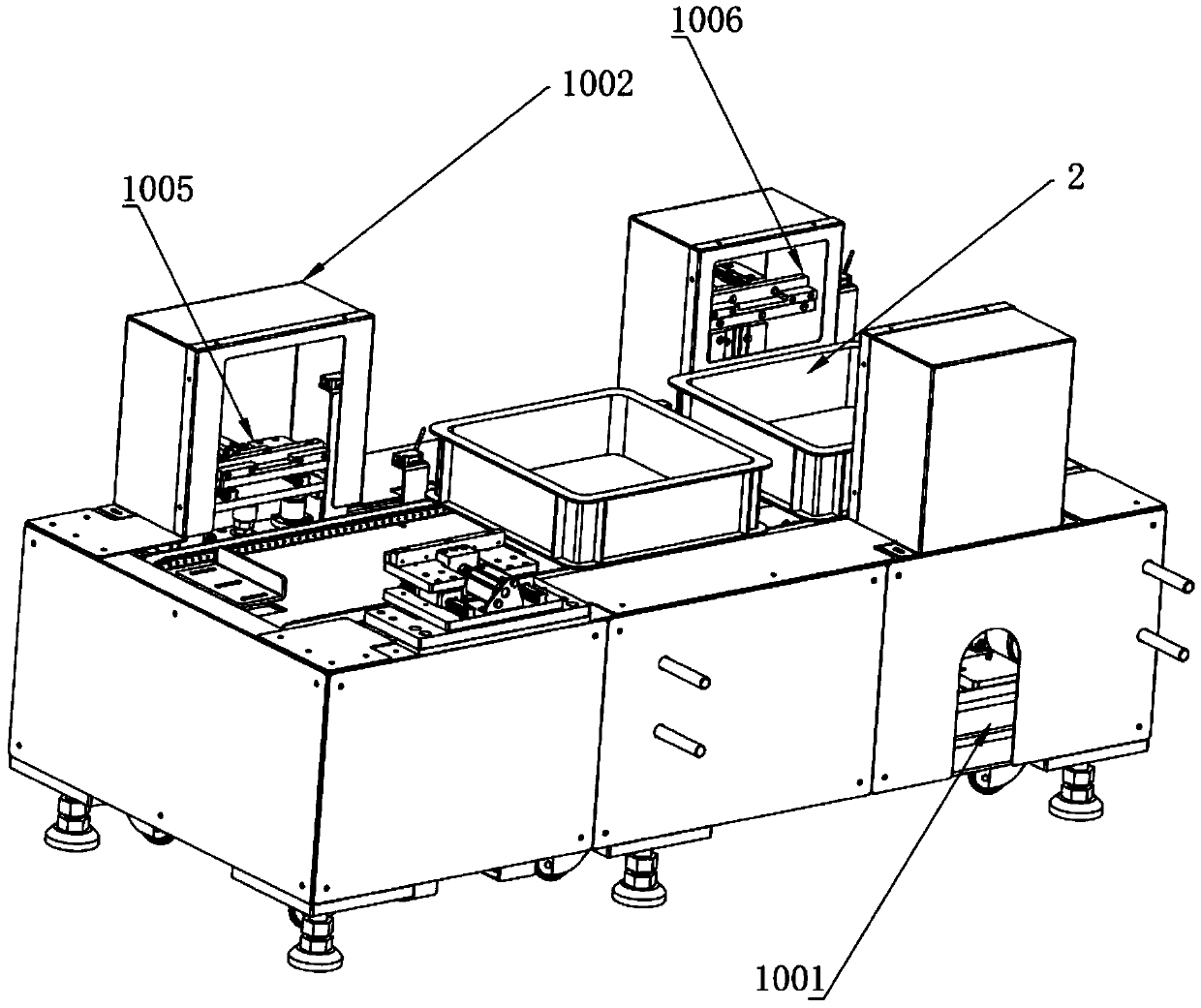

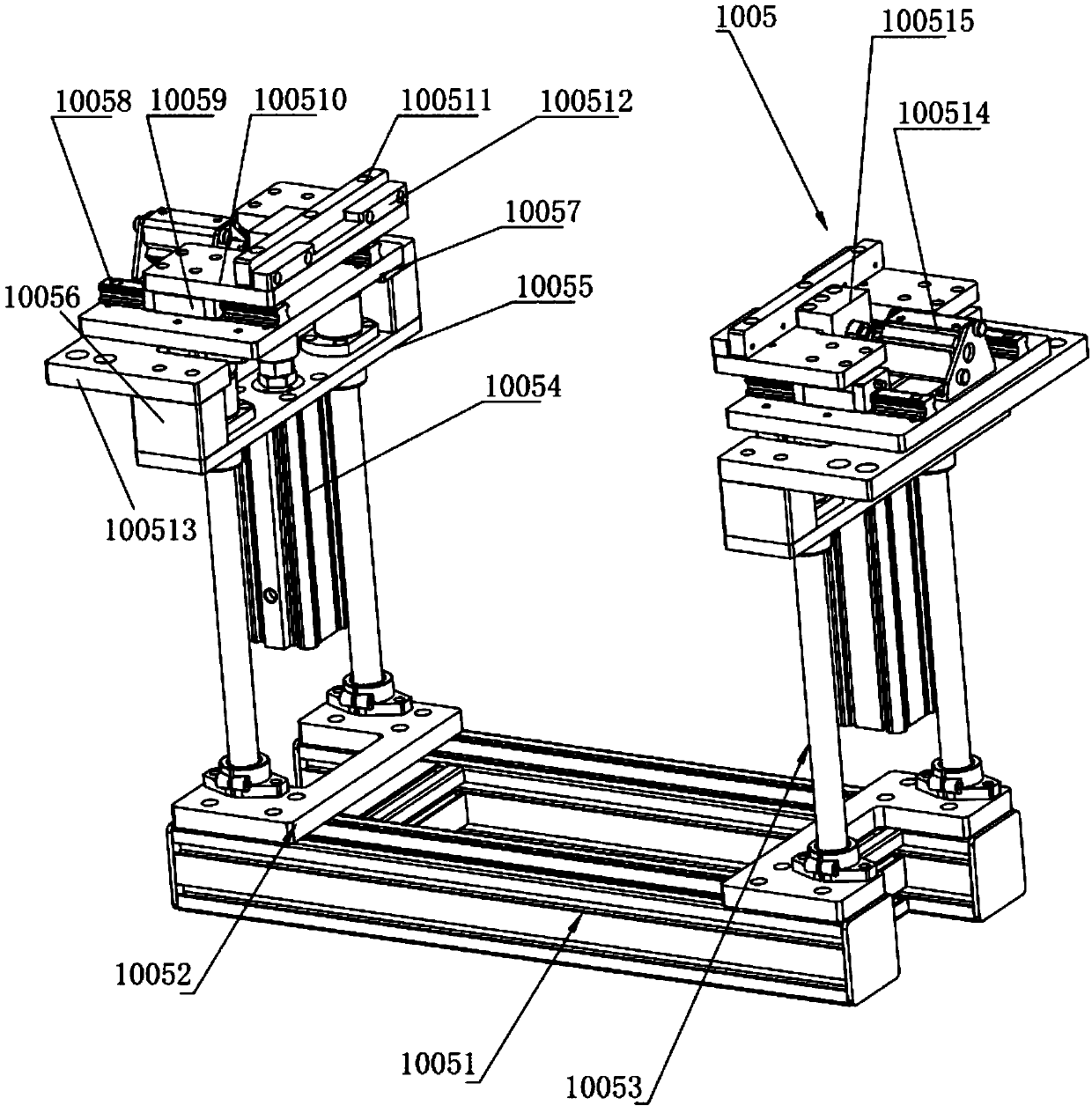

[0035] like figure 1 As shown, the unloading mechanism for a fully automatic laser marking device includes a welding frame 1001, in which a motor assembly 1004, a conveyor belt assembly 1003, a plurality of material boxes 2, and a pair of first tray lifting assemblies are respectively arranged. 1006, a pair of second tray lifting assemblies 1005, a plurality of blocking assemblies 1007 and jacking assemblies 1008, the motor assembly 1004 drives the conveyor belt assembly 1003 to move the magazine 15 positioned on the conveyor belt assembly 1003, each first pallet lifting assembly 1006 1. The second tray lifting assembly 1005 is provided with a lifting assembly cover 1002 on the periphery.

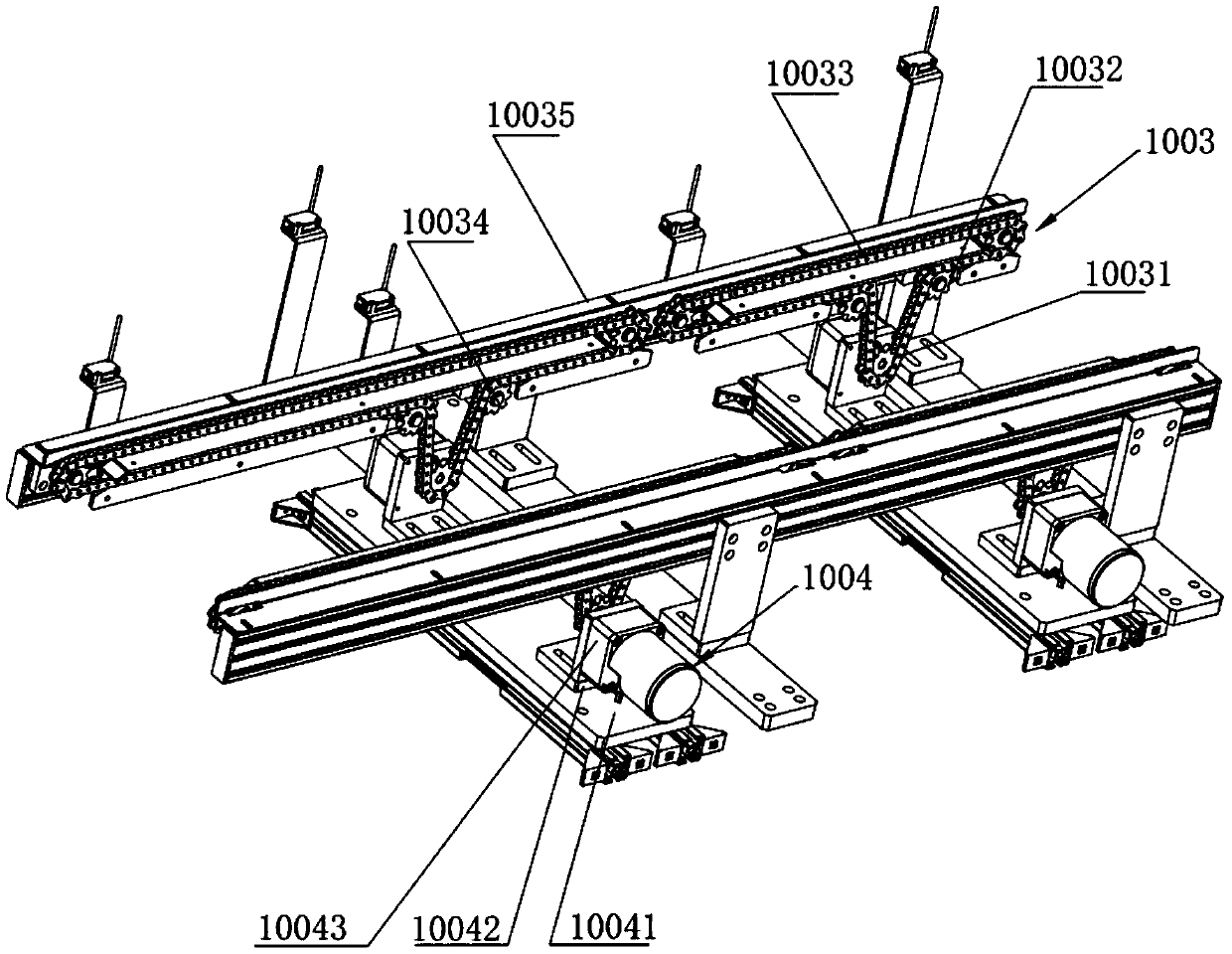

[0036] like figure 2 As shown, the specific structure of the motor assembly 1004 is as follows:

[0037] It includes a plurality of first bottom plates 10041 arranged on the welding frame 1001, a pair of mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com