Automatic feeding and discharging device for material trays

A technology of automatic loading and unloading and feeding trays, which is applied in the direction of destacking of objects, conveyor objects, transportation and packaging. The effect of taking, ensuring feeding, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention provides an automatic loading and unloading device for material trays.

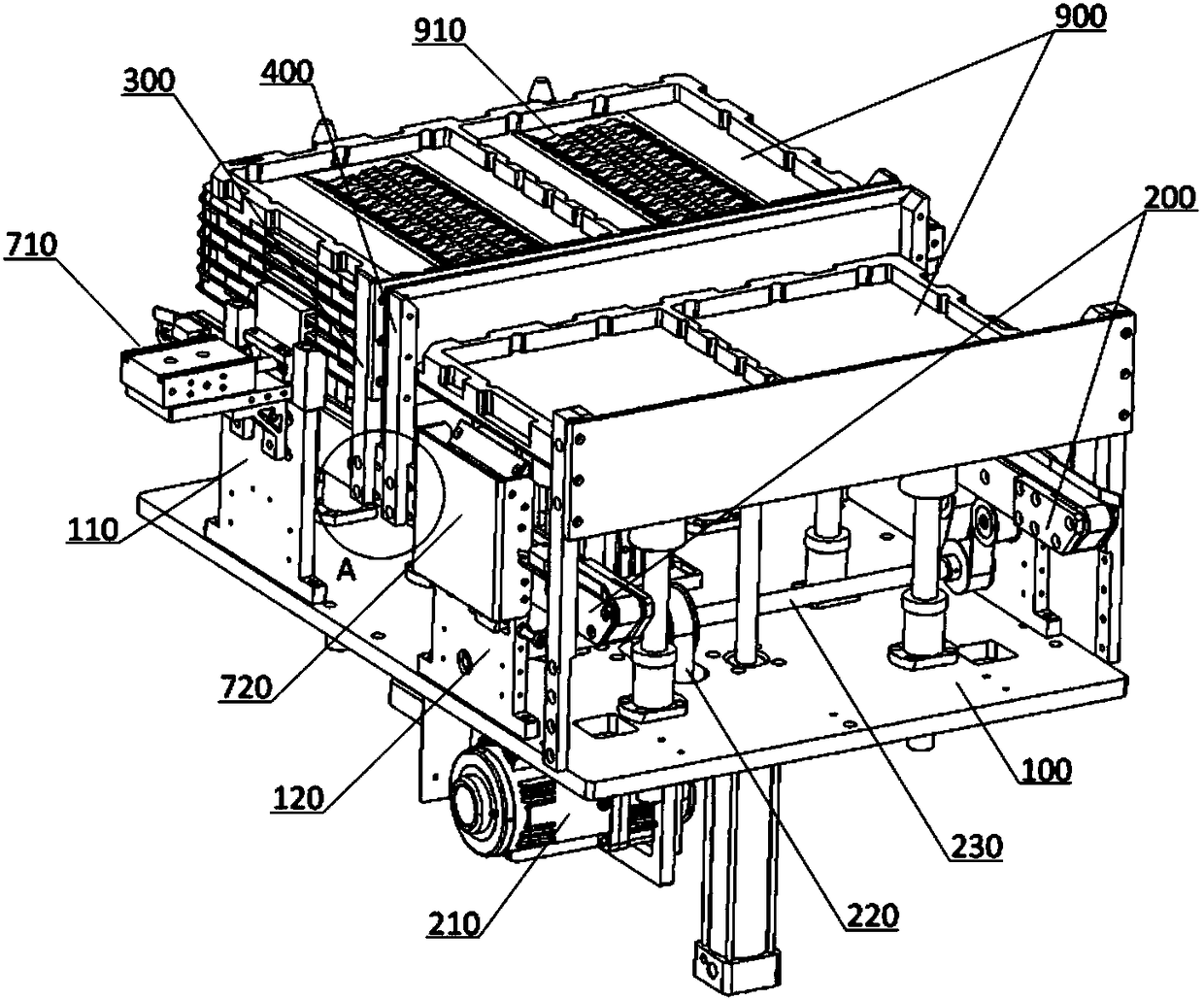

[0042] refer to figure 1 , figure 1 It is a structural schematic diagram of an embodiment of an automatic loading and unloading device for material trays of the present invention.

[0043] Such as figure 1 As shown, in the embodiment of the present invention, the automatic loading and unloading device of the material tray 900 includes a bottom plate 100, two opposite belt line mechanisms 200, a first material rack 300, a second material rack 400, and a first jacking mechanism 500 and the second jacking mechanism 600. Each belt line mechanism 200 is disposed above the bottom plate 100 through the first support plate 110 and the second support plate 120 . The base plate 100 is provided with a second speed-regulating motor 210 for driving the belt line mechanism 200. The second speed-regulating motor 210 is fixed on the bottom of the base plate 100, and its output end passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com