Solid adhesive with function of preventing adhesion each other and making, packing method thereof

A manufacturing method and technology of solid objects, applied in the direction of adhesives, etc., can solve problems such as time-consuming, performance degradation of hot-melt adhesives, difficulty in peeling off containers and hot-melt adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

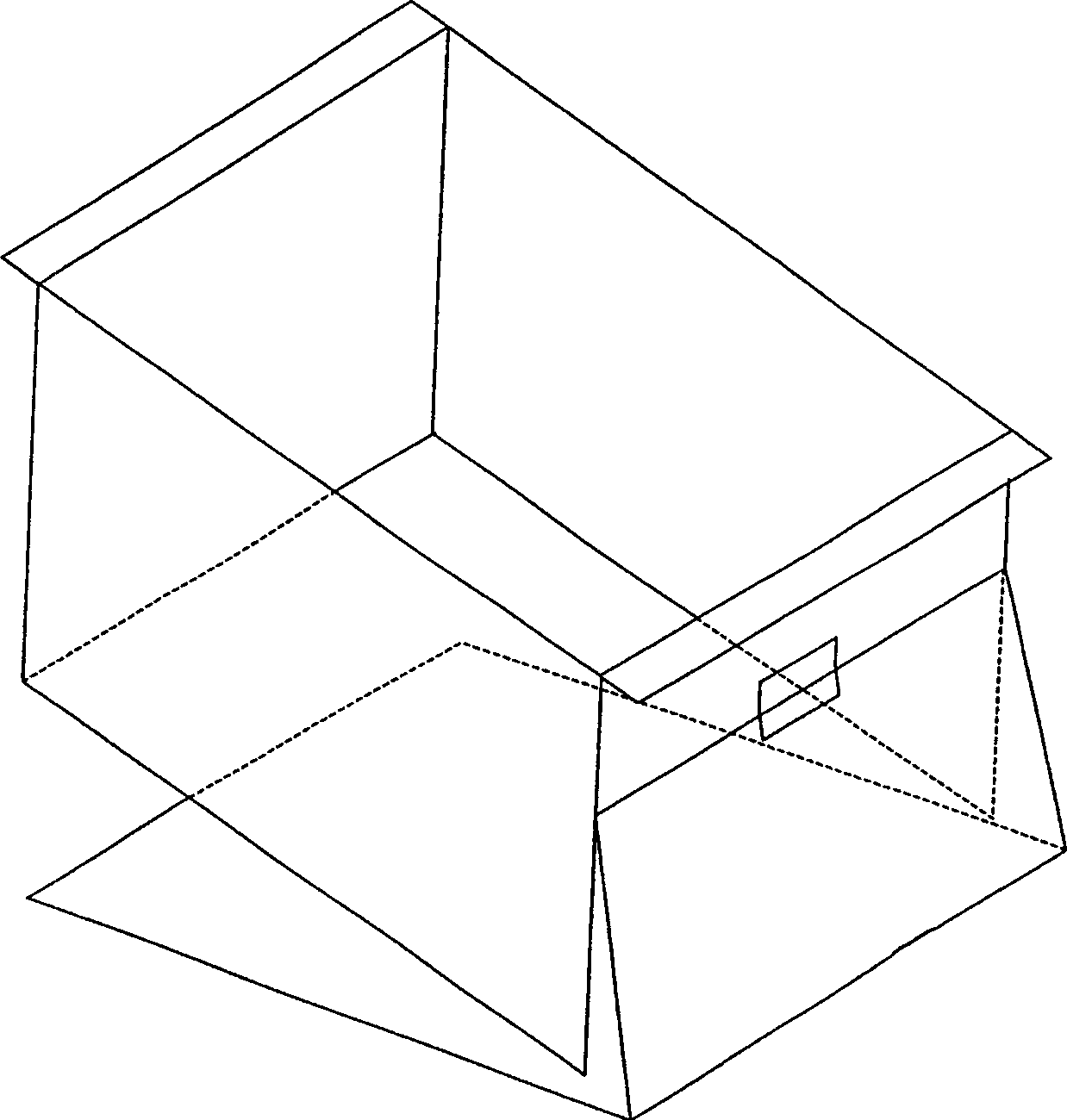

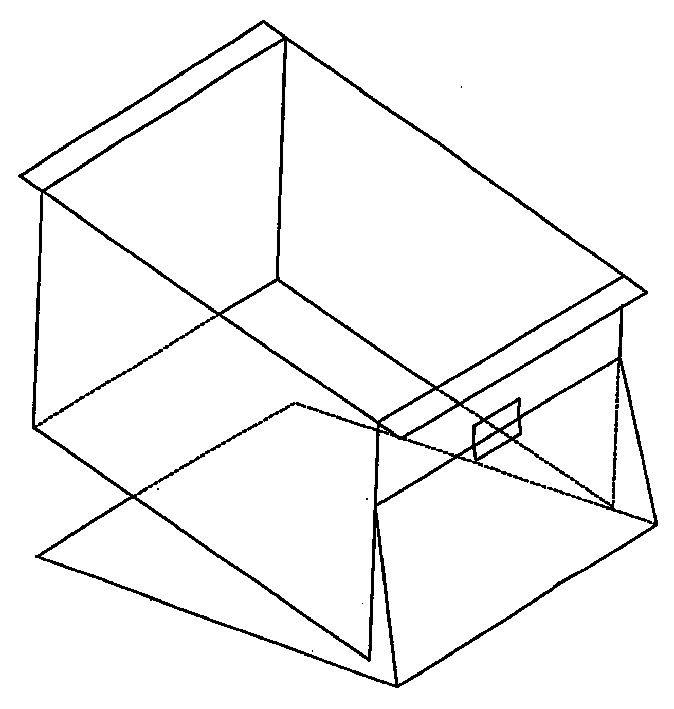

[0030] Xiang Ru figure 1 The shown internal dimensions are 150mm×200mm, and the adhesive block molding container with a height of 100mm is pasted with a silicon sheet on the side and inner bottom of the container, and 2.5kg of fluid hot-melt adhesive is injected at 150°C. At this time, the bottom plate can be opened and closed through the hinge. After the hot-melt adhesive is completely cured by letting it cool, when a round rod with a diameter of 40mm is directly applied to the bottom with a load of 40kgf when the bottom plate is opened, the hot-melt adhesive will easily Peel off drops from container.

Embodiment 2

[0032] Sprinkle the synthetic paraffin wax that particle diameter is 5~7 microns to the hot-melt adhesive made in embodiment 1, wipe off excess part with cloth, obtain the adhesion uniformity to surface simultaneously, make to prevent mutual Surface-adhesive hot-melt adhesive solids. The amount of synthetic paraffin adhering to the solid matter was calculated by measuring the weight, and it was 0.05% by weight relative to the whole solid matter.

Embodiment 3

[0034] The properties of the hot-melt adhesives obtained in Examples 1 and 2 were tested respectively. The viscosity was in accordance with Japanese JIS K6863, the 180-degree peel was in accordance with JIS K6862 B method, and the softening point was in accordance with JIS Z0237. The results are shown in Table 1.

[0035] Example 1

[0036] As a result, the viscosity, softening point, and 180-degree peel strength of the hot-melt adhesive coated with synthetic paraffin compared with the uncoated hot-melt adhesive showed roughly the same value, indicating that 0.05% by weight of wax does not affect any properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com