Method and device for achieving batched removing of burrs in hole of PCB based on numerical control machine tool

A technology of PCB board and CNC drilling machine, applied in the direction of cleaning method using tools, grinding drive device, cleaning method and utensils, etc., can solve the problems of low efficiency, hidden danger of quality, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

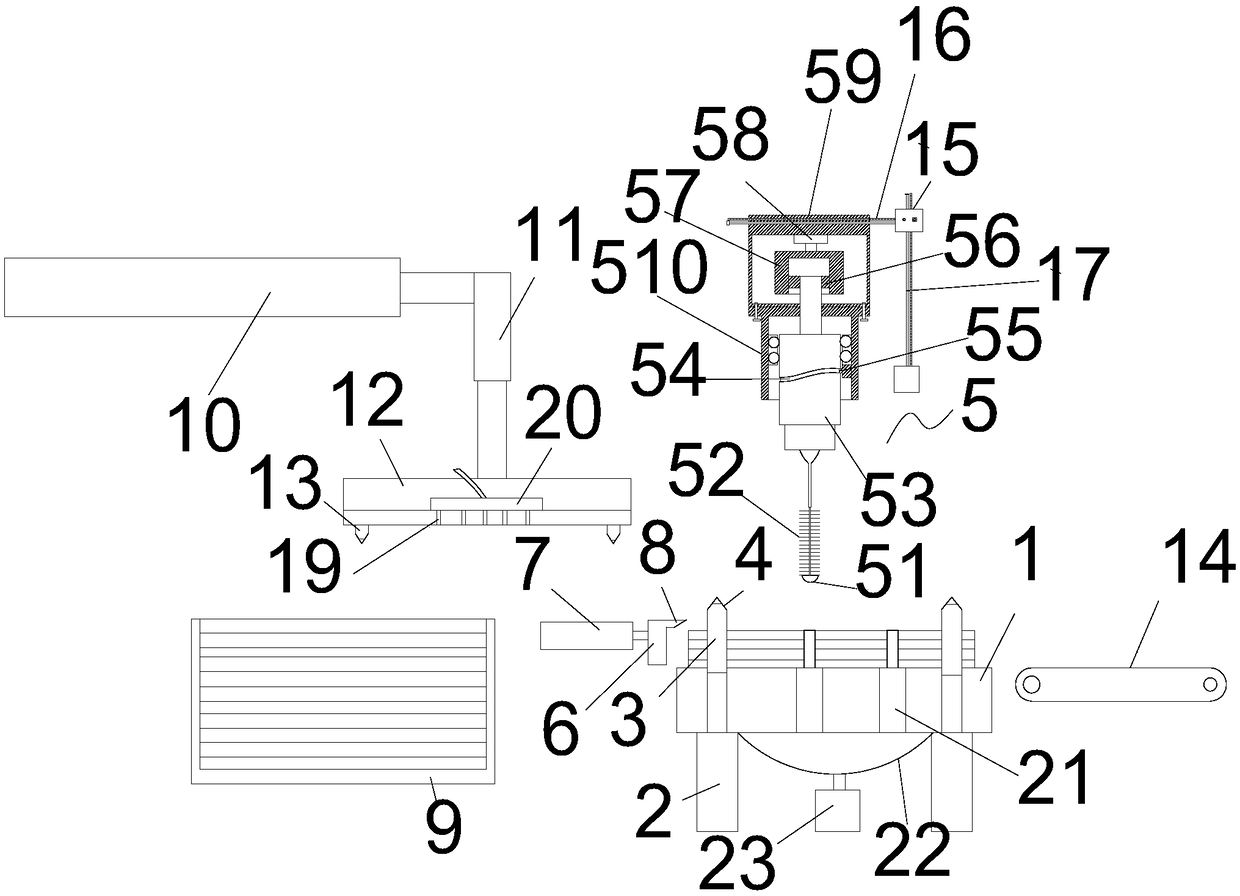

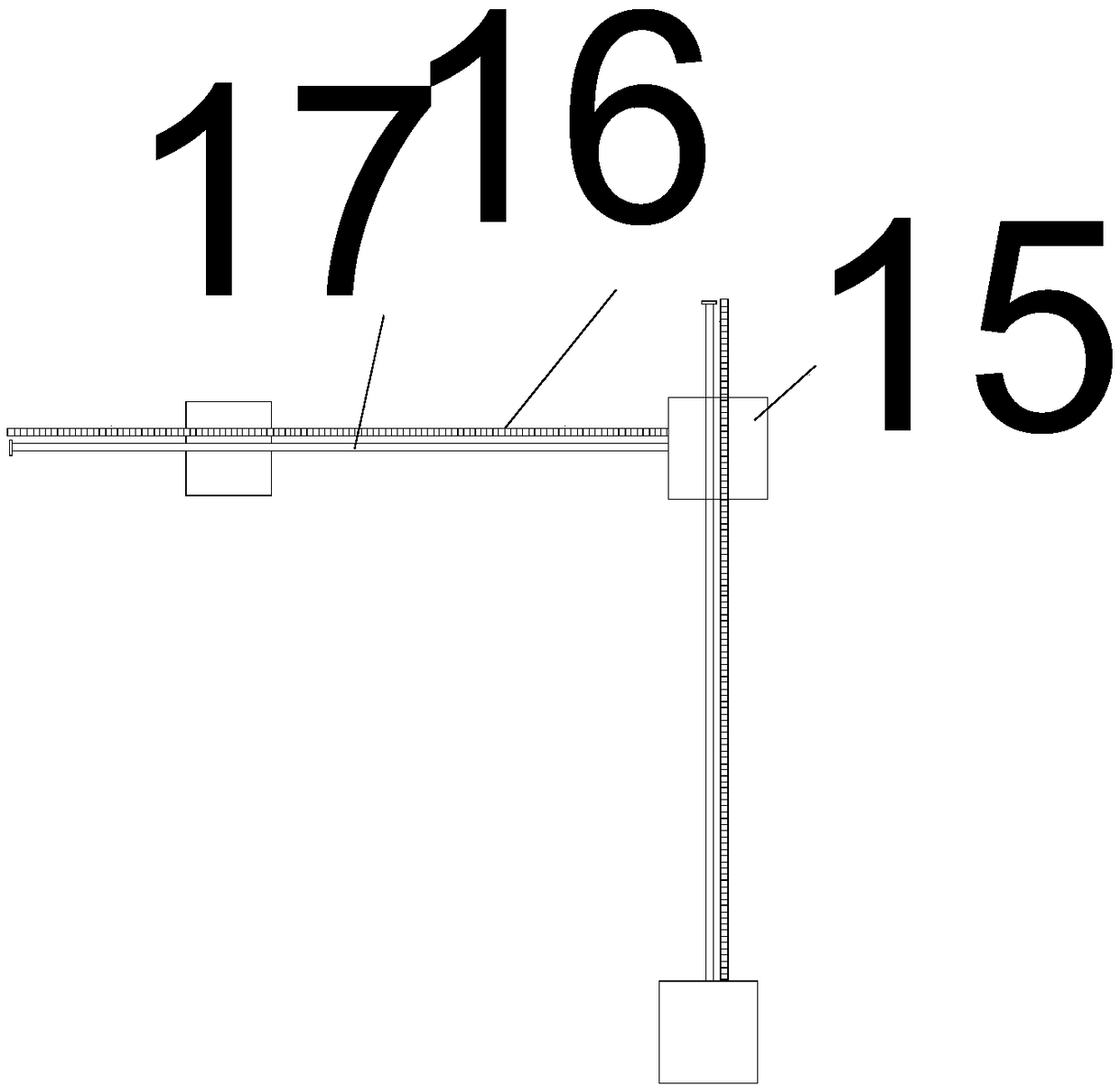

[0017] Such as Figure 1-2 The device for deburring PCB board holes in batches based on a CNC drilling machine as shown includes a PCB board moving mechanism and a PCB board deburring mechanism; the PCB board deburring mechanism includes a machine tool table 1, and the machine tool table 1 bottom is installed There is a first push-pull device 2, the first push-pull device 2 is connected with a positioning pin 3, and the top of the positioning pin 3 is formed with a first tapered part 4 matching with the positioning hole of the PCB board; a deburring drill structure 5 is installed above the machine table 1 , the side of the machine tool table 1 is equipped with an L-shaped pressure plate 6, the L-shaped pressure plate 6 is connected with a second push-pull device 7, and the end surface of the L-shaped pressure plate 6 is formed with a second tapered portion 8 that cooperates with the PCB board; the PCB board moving mechanism includes The frame 9 of the stacked PCB board and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com