390MPa grade cold-rolled phosphorus-containing IF high-strength steel strip and LF-RH duplex production process thereof

A LF-RH, production process technology, used in the manufacture of converters, lighting and heating equipment, bell-type furnaces, etc., can solve the problems of surface inclusion defects, high production costs, and long production cycles of steel strip products. The effect of reducing surface inclusion defects, shortening production cycle, and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

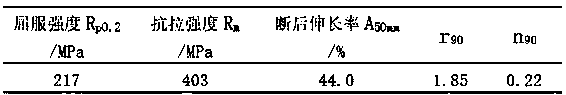

Embodiment 1

[0023] In this example, the composition of the steel strip in weight percentage is C: 0.0050%, Si: 0.0300%, Mn: 0.55%, P: 0.0700%, S: 0.0053%, Als: 0.0314%, Nb: 0.0500%, Ti: 0.0350 %, B: 0.0005%. The specific production process is as follows:

[0024] (1) Converter molten steel smelting: put the blast furnace molten iron into the converter, tapping C=0.044%, S=0.011%, O=0.0599%; the tapping temperature is 1678°C, no deoxidizer, alloy and synthetic slag are added during the tapping process of the converter and small lime;

[0025] (2) Refining of LF molten steel: transfer the molten steel obtained in the converter to the LF furnace to fix the oxygen, add 0.17kg of aluminum wire for every 0.0001% [O]; add 8.34kg of lime per ton of molten steel after the addition of aluminum wire, LF adopts micro positive pressure operation, Control the Als content in molten steel to 0.0089%, and the RH arrival temperature to 1653°C;

[0026] (3) RH molten steel refining: The molten steel is v...

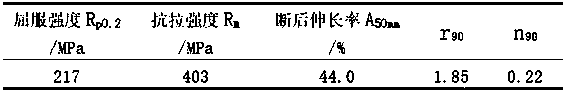

Embodiment 2

[0034] The composition of the steel strip in this embodiment is calculated by weight percentage, C: 0.0048%, Si: 0.0430%, Mn: 0.60%, P: 0.0550%, S: 0.0042%, Als: 0.0400%, Nb: 0.0350%, Ti: 0.0207%, B: 0.0010%. The specific production process is as follows:

[0035] (1) Converter molten steel smelting: put the blast furnace molten iron into the converter, tapping C=0.056%, S=0.009%, O=0.0482%; the tapping temperature is 1675°C, no deoxidizer, alloy, synthetic slag is added during the tapping process of the converter and small lime;

[0036] (2) Refining of LF molten steel: transfer the molten steel obtained in the converter to the LF furnace to fix the oxygen, add 0.17kg of aluminum wire for every 0.0001% [O]; add 8.34kg of lime per ton of molten steel after the addition of aluminum wire, LF adopts micro positive pressure operation, Control the Als content in molten steel to 0.0097%, and the RH arrival temperature to 1651°C;

[0037] (3) RH molten steel refining: The molten s...

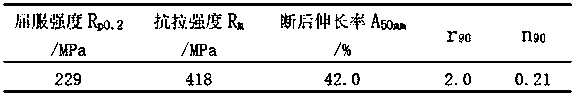

Embodiment 3

[0045] In this embodiment, the composition of the steel strip is calculated by weight percentage, C: 0.0047%, Si: 0.0550%, Mn: 0.588%, P: 0.0601%, S: 0.0080%, Als: 0.0200%, Nb: 0.0384%, Ti: 0.0150%, B: 0.0008%. The specific production process is as follows:

[0046] (1) Converter molten steel smelting: put blast furnace molten iron into converter, tapping C=0.042%, S=0.008%, O=0.0557%; tapping temperature is 1676°C, no deoxidizer, alloy and synthetic slag are added during the tapping process of converter and small lime;

[0047] (2) Refining of LF molten steel: Transfer the molten steel obtained in the converter to the LF furnace to fix the oxygen, add 0.17kg of aluminum wire for every 0.0001% [O]; add 8.34kg of lime per ton of molten steel after the addition of aluminum wire, and LF adopts micro positive pressure operation, Control the Als content in molten steel to 0.0093%, and the RH arrival temperature to 1656°C;

[0048] (3) RH molten steel refining: The molten steel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com