Combined hood-type furnace annealing method and annealing furnace device thereof

A bell furnace and combined technology, which is applied in the annealing field of the combined bell furnace, can solve the problems that the heat cannot be recycled, the labor intensity is high, the equipment and production costs are reduced, and the equipment investment and operating costs can be saved, and the heating can be improved. and cooling efficiency, the effect of shortening the annealing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

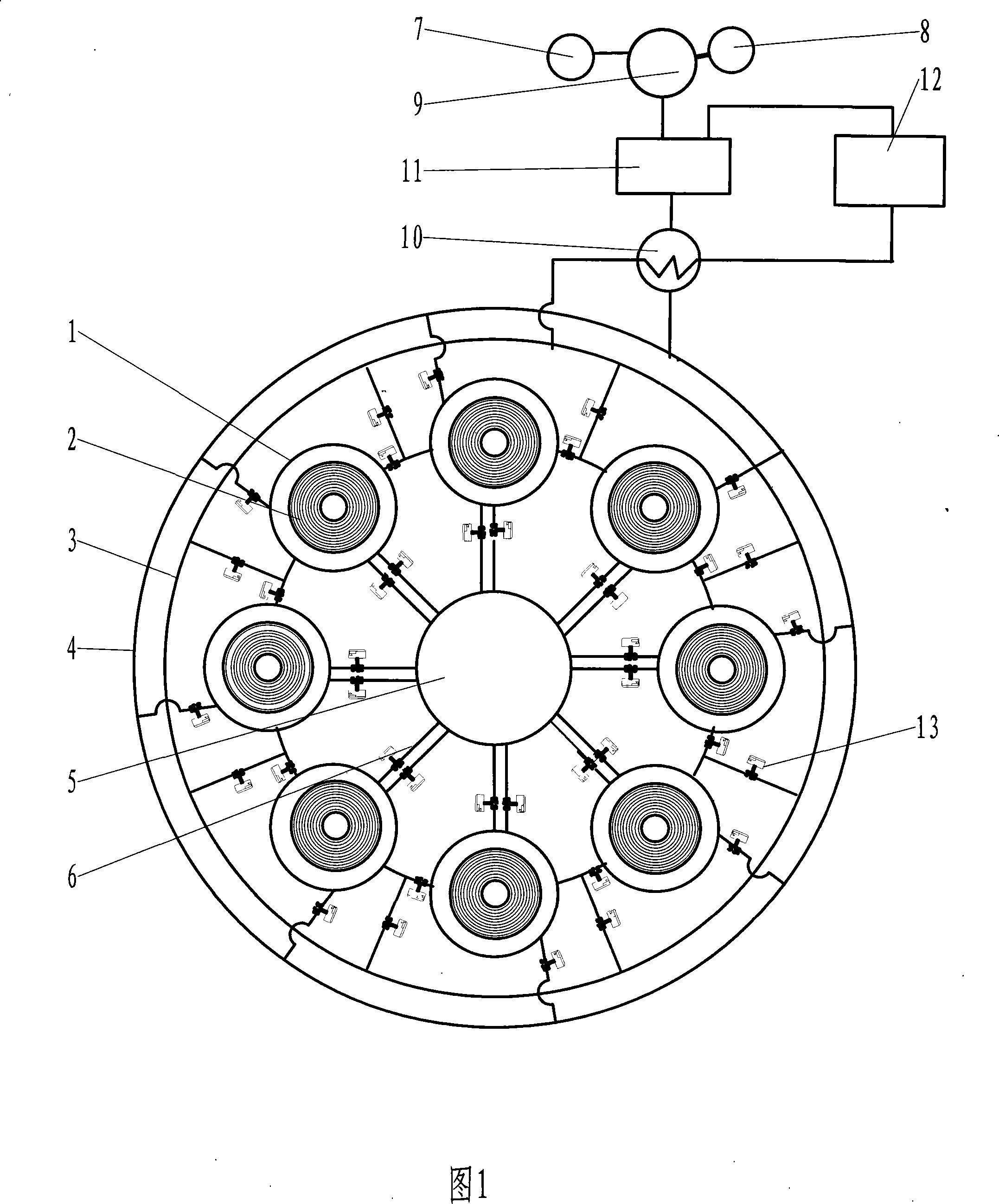

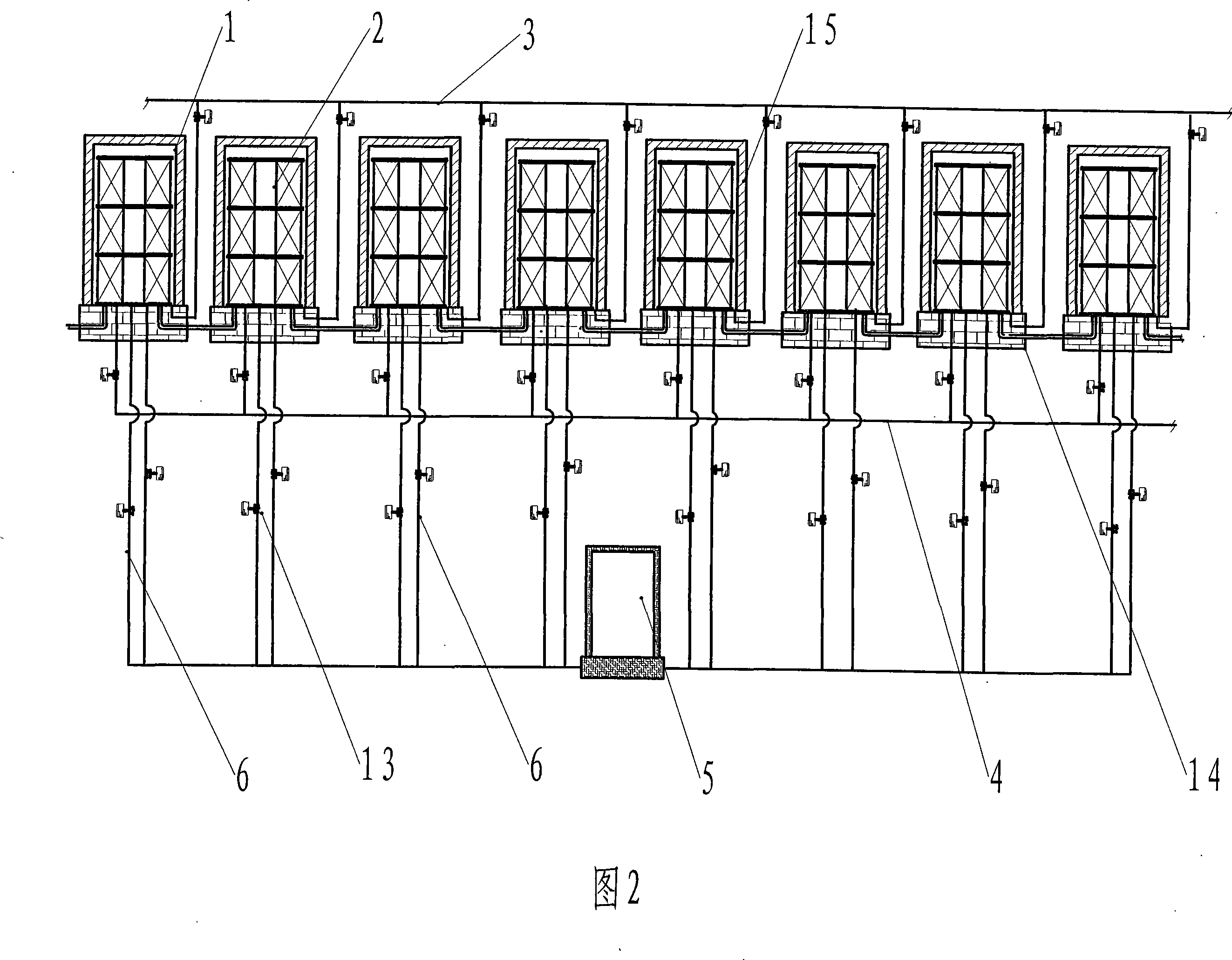

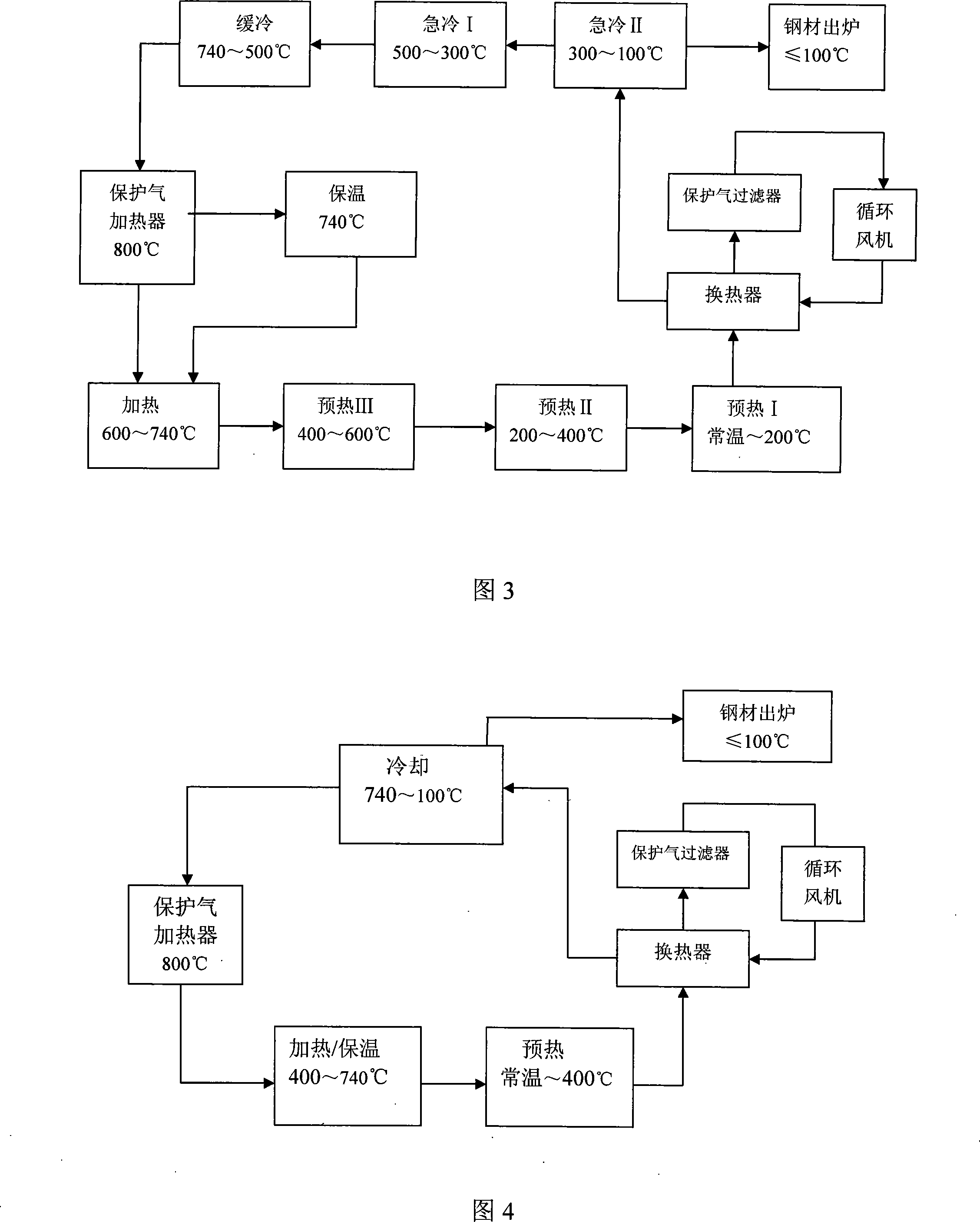

[0019] The present invention, as shown in Figure 1 and Figure 2, is an annealing furnace device composed of 8 bell furnaces, and the annealed material is cold-rolled strip steel. The annealing furnace device includes bell furnace 1, hydrogen production equipment 8, nitrogen generator 7, protective gas supplement tank 9, protective gas filter 11, heat exchanger 10, circulating fan 12, cooling and cleaning protective gas pipe network 4, turbid gas The discharge pipe 3 has a furnace platform 14 and a protective cover 15 in the bell furnace 1 . Figure 1 shows a circular arrangement structure, 8 bell furnaces are installed in series, and are connected from the outlet of the previous bell furnace to the entrance of the next bell furnace in turn. Each bell-type furnace communicates with the cool and clean protective gas pipe network 4 and the turbid gas discharge pipe 3 respectively. The shielding gas heater 5 is located in the center of the device, and the heater is electric heatin...

Embodiment 2

[0025] The annealing process and temperature of another solution of the present invention are shown in Figure 4, which is an annealing furnace device composed of three bell furnaces, and the material to be annealed is a steel product. The hot net shielding gas heated in the shielding gas heater first enters the bell-type furnace in the heating / insulation stage, and enters the bell-type furnace in the preheating stage from the heating / insulation stage, and the shielding gas coming out of the preheating stage After heat exchange, filtration and purification, it enters the cooling stage through the circulating fan, and the protective gas that takes out heat from the cooling stage returns to the protective gas heater; the annealing of steel products is carried out according to the process of preheating, heating / insulation, and cooling, and the annealed steel products are cooled to Baked out below 100°C. The composition of the protective gas used is: nitrogen: 70%; hydrogen: 30%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com