Steel for battery shell with excellent planar isotropism and its production

An isotropic, battery shell technology, applied in the direction of manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problems of grain and cementite becoming thicker, high production cost, and more alloy addition, etc., to achieve excellent various Isotropic, low production cost, less alloying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Three embodiments of the present invention and a comparative example see the following table 1:

[0034]

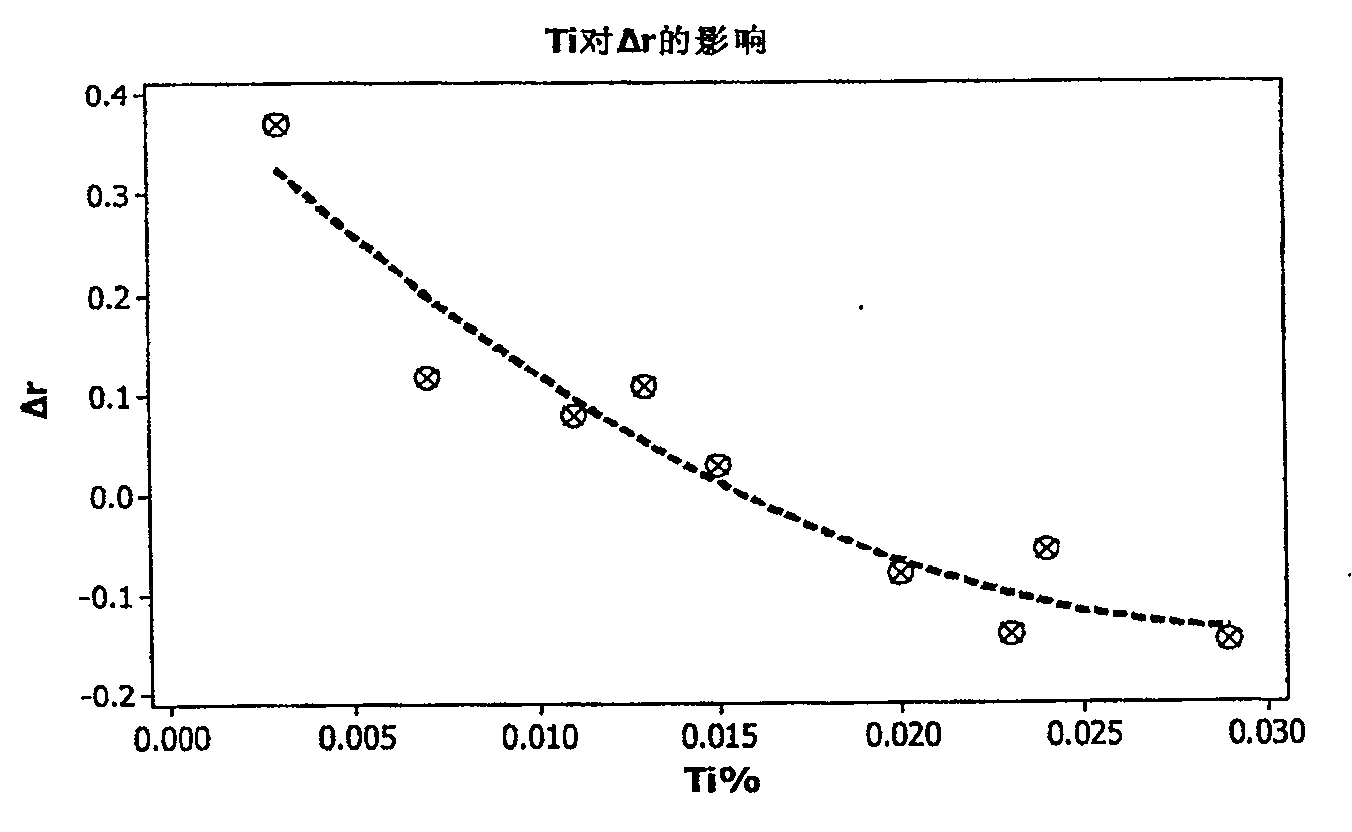

[0035] The process control of Example A is: hot rolling control: heating temperature ≤ 1270°C, finish rolling temperature 870°C, coiling temperature 640°C; cold rolling deformation 76%, bell annealing temperature 650°C. From figure 1 , figure 2 It can be seen that the grains of the material after adding Ti are fine, and the cementite is also fine. The fine crystal grains can not only beautify the appearance of the battery case, but also improve the secondary processability such as flanging. figure 1 It is a ferrite structure (ASTM standard: grade 11), figure 2 For cementite structure. Such as image 3 As shown, in the case of low-carbon aluminum-killed steel, the Δr value decreases with the increase of Ti, but if too much Ti is added, the Δr value decreases too much and becomes negative, which is not conducive to stamping. See Figure 4 , Δr can be redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com