A temperature control method for an annealing furnace zone

A temperature control method and annealing temperature technology, applied in the direction of temperature control using electric mode, auxiliary controller with auxiliary heating device, furnace, etc., can solve the problems affecting the annealing quality of the next steel strip, unfavorable product qualification rate, temperature Inaccurate control and other issues to achieve the effect of protecting the annealing quality, shortening the processing time of broken belts, and improving the qualified rate of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described.

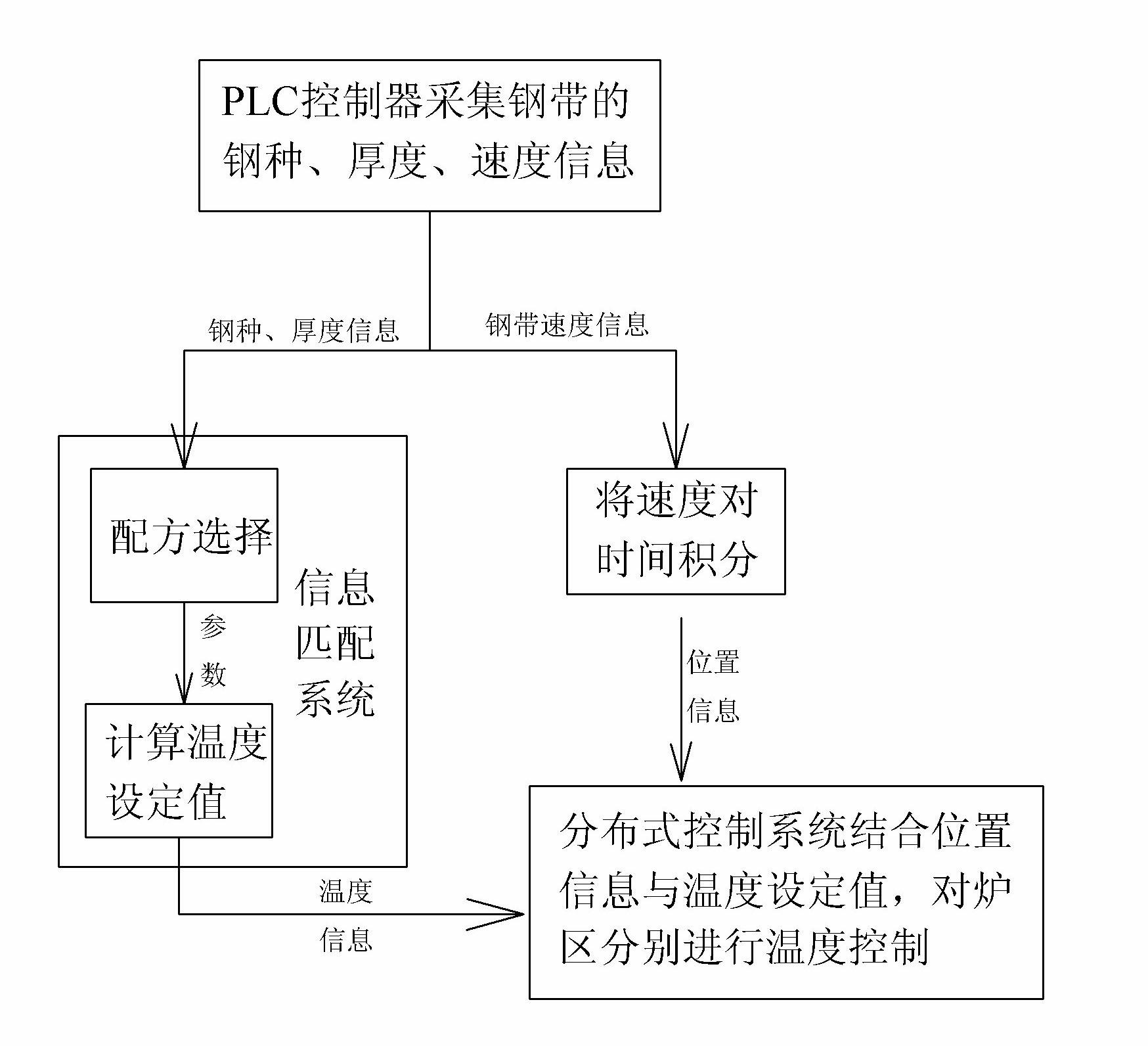

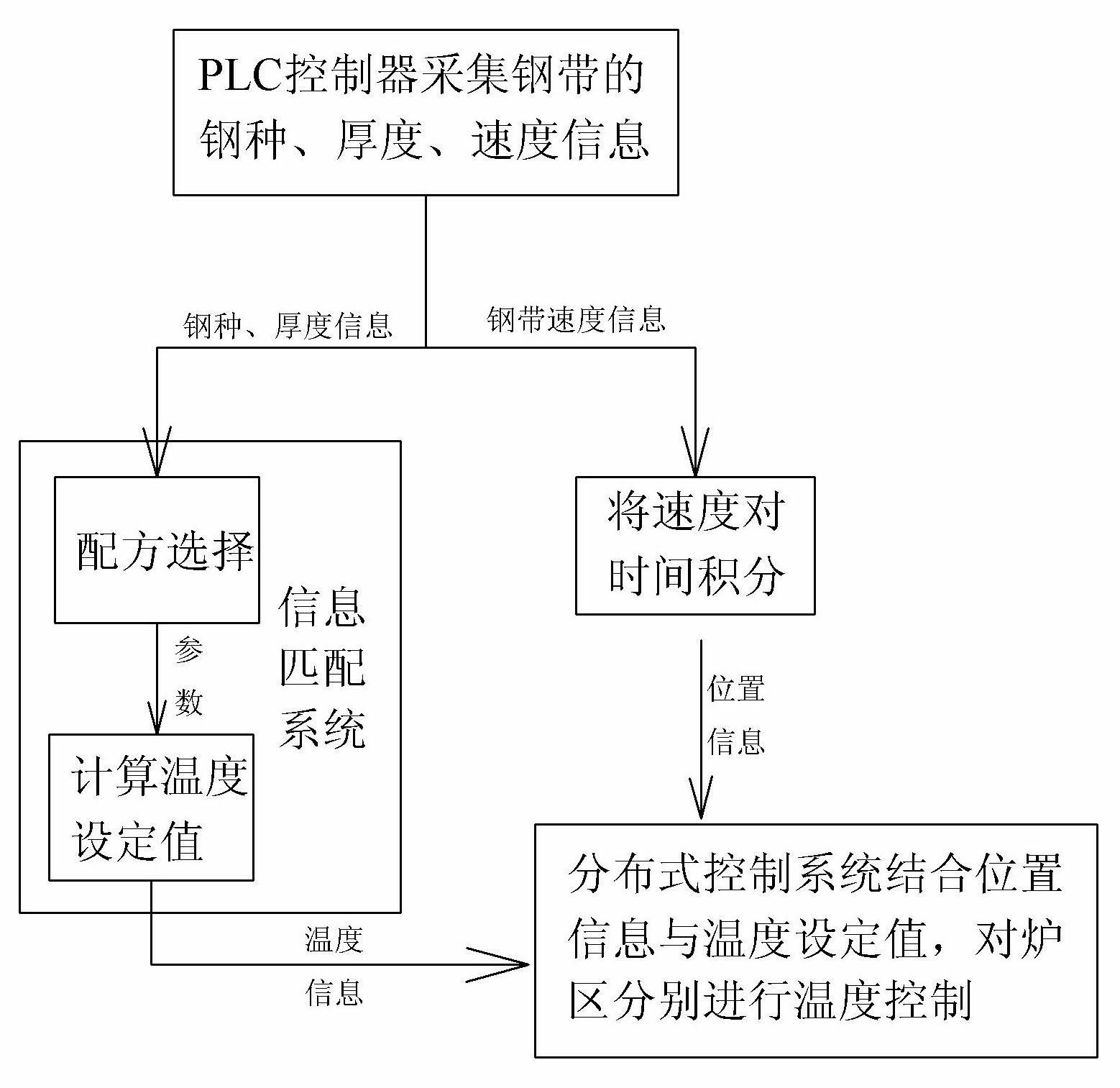

[0012] Such as figure 1 , the temperature control method of the furnace area of the annealing furnace, including the following steps: 1), information collection: the PLC controller collects the steel type, thickness, and speed information of the steel strip entering the furnace area, and automatically uploads the collected information; 2 ), data processing: the information matching system searches for the corresponding formula in the system according to the steel type and thickness information of the steel strip, calculates the annealing temperature required for the steel strip according to the parameters in the corresponding formula, and calculates the required annealing temperature according to the steel strip The speed information calculates the position information of the steel belt in the furnace area at different times; 3), set the temperature: the distributed cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com