Automatic magnetic strip passing machine

A technology of automatic threading and magnetic strip, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of magnetic strip slipping, adhesion of dust and impurities, high production cost, etc., to avoid slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

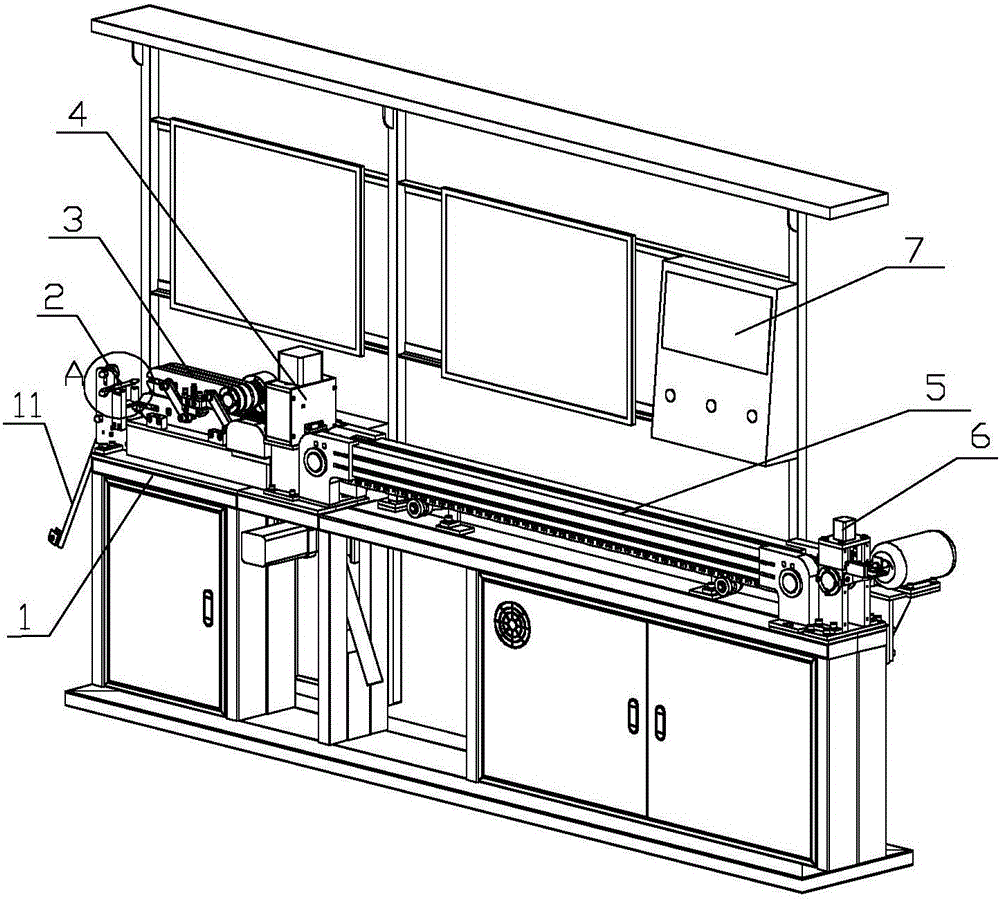

[0027] Such as figure 1 As shown, an automatic magnetic strip threading machine includes a frame 1 and a magnetic flux leakage detection mechanism 2 sequentially located on the frame 1, a magnetic strip tractor 3, a magnetic strip trimming machine 4, a conveyor belt 5, and a magnetic threading guide machine 6 and a controller 7, the frame 1 is also provided with a guide rod 11 and a pinch wheel, and the magnetic stripe passes through the guide rod 11, the pinch wheel, the magnetic flux leakage detection mechanism 2 and the magnetic strip tractor 3 in sequence.

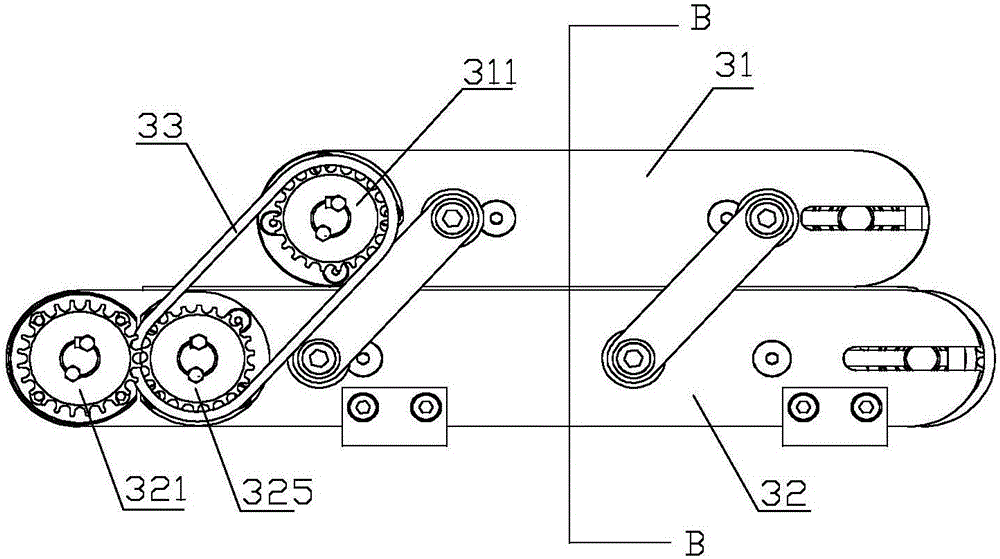

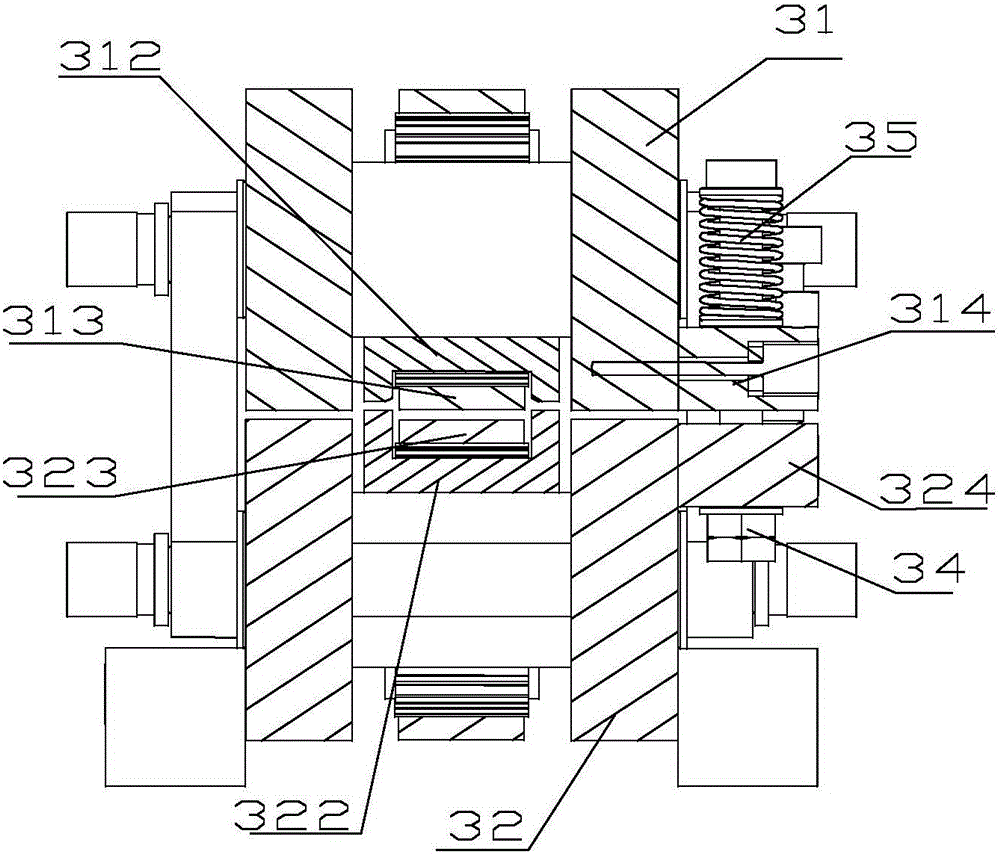

[0028] Such as figure 2 and image 3 As shown, the magnetic strip tractor 3 includes two conveyors, which are respectively an upper conveyor 31 located above and a lower conveyor 32 located below, the upper conveyor 31 and the lower conveyor 32 are connected as one, and the upper conveyor 31 and the lower conveyor 32 are connected as one. Sending machine 31 is provided with upper guide groove 312 on the side opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com