Manufacturing equipment assembly of training pants and manufacturing method thereof

A technology for manufacturing equipment and manufacturing methods, applied in medical science, bandages, etc., can solve the problems of complex production equipment, cumbersome processing technology, cumbersome manufacturing methods, etc., and achieve the effects of high production efficiency, simple process, and increased wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

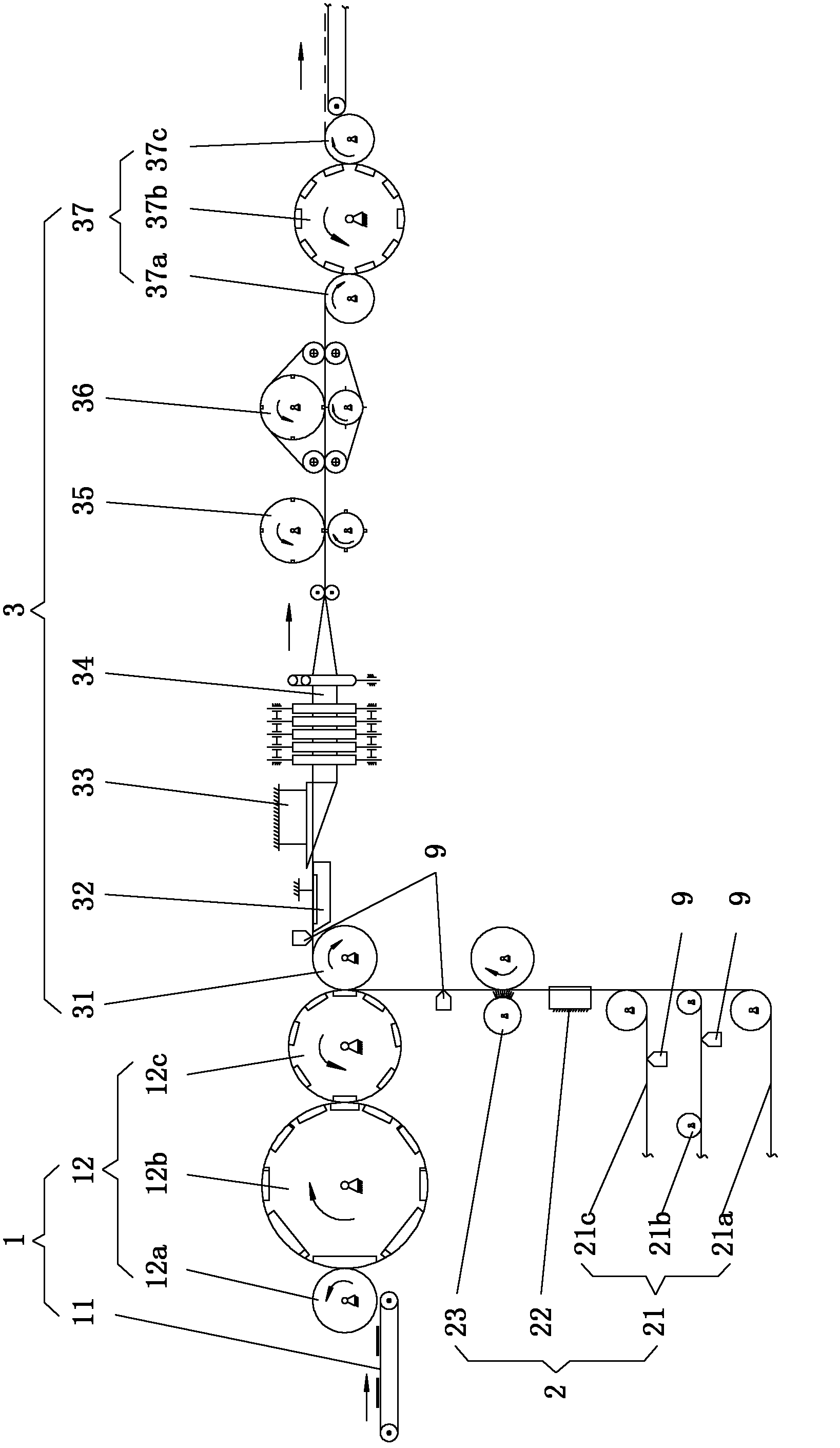

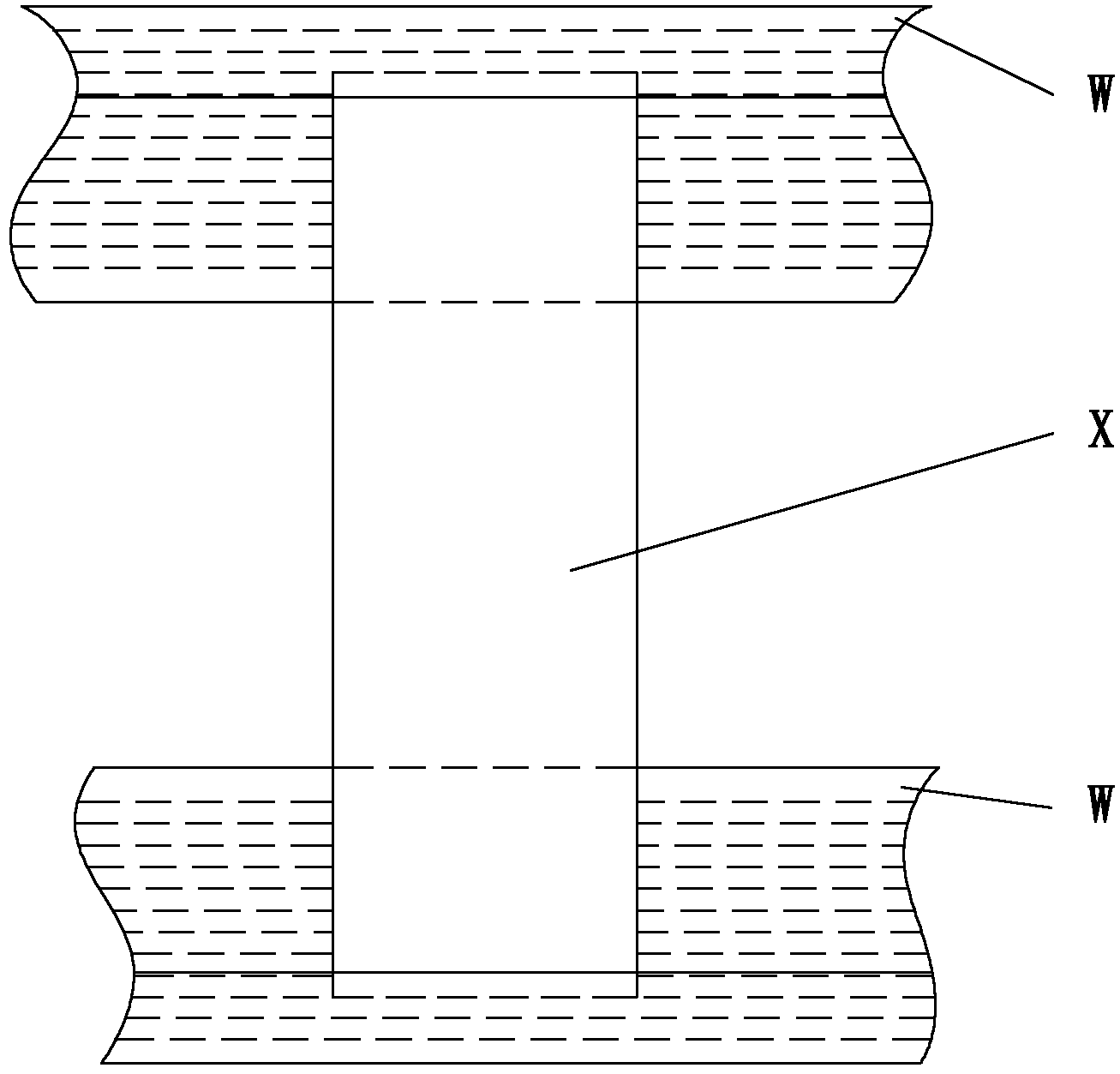

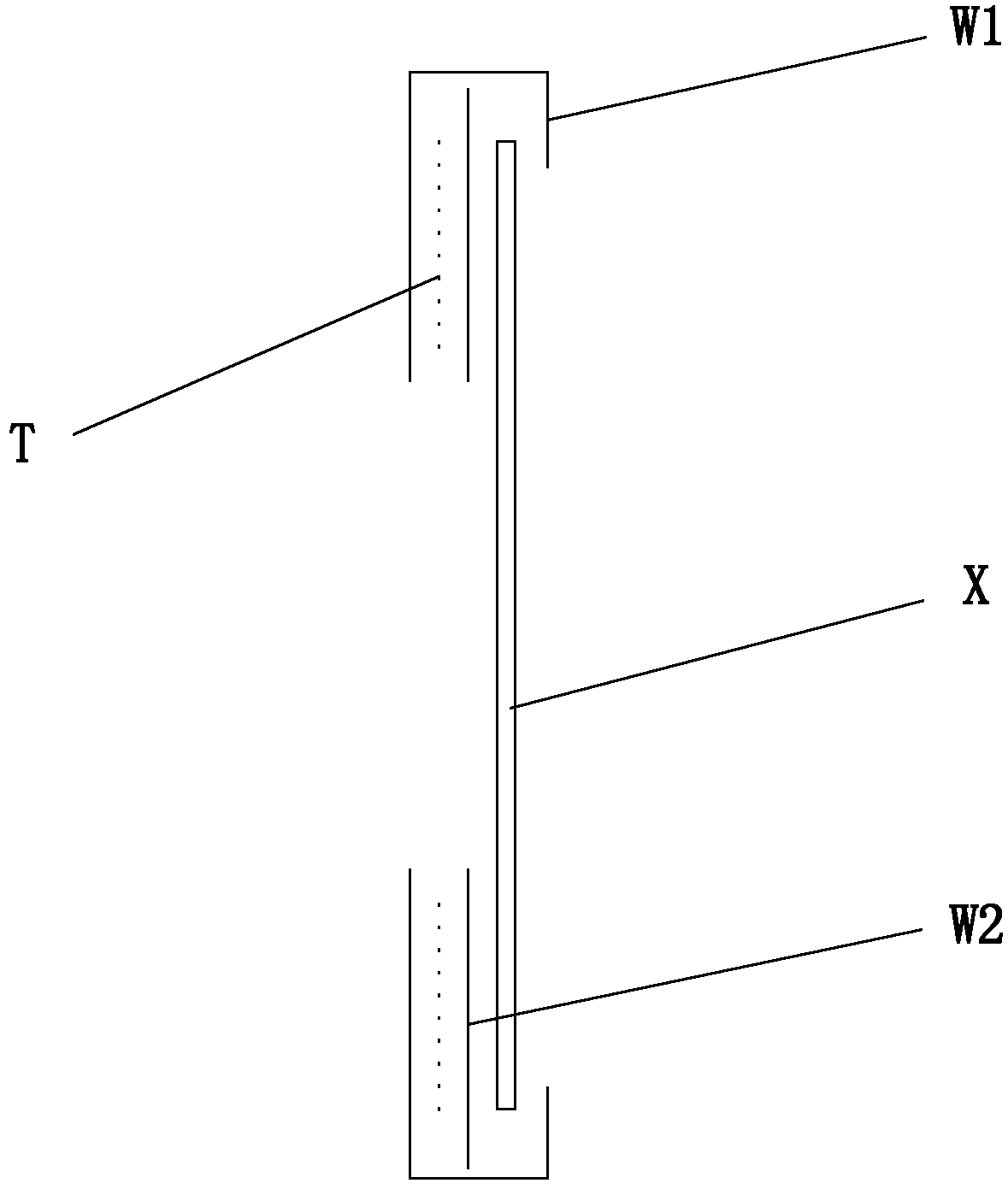

[0032] See figure 1 , a manufacturing equipment assembly for training pants, which has an absorbent body production line 1, a waistline production line 2, and a finished product production line 3. The above-mentioned absorbent body production line 1 has an absorbent body manufacturing conveying unit 11 and an absorbing body transversal conveying unit 12 arranged continuously in sequence, The absorber transfer unit 12 has a transfer wheel 12a, a transfer wheel 12b, and a transfer wheel 12c arranged continuously; the waist production line 2 has a waist manufacturing unit 21, a waist center distance adjustment unit 22, and a waist partial elastic breaking unit arranged successively. 23. The waist manufacturing unit 21 has a waist outer layer fabric delivery device 21a, an elastic material delivery device 21b and a waist inner layer fabric delivery device 21c; the finished product production line 3 has an absorber and a waist connection unit 31, a waist hemming unit 32, Folding un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com