Planetary gear train advantageously used in a servo motor system, method and servo motor system using the planetary gear train

A planetary gear train, servo motor technology, applied in the direction of elements with teeth, servo motor components, gear transmissions, etc., can solve problems such as not considering longer approach stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

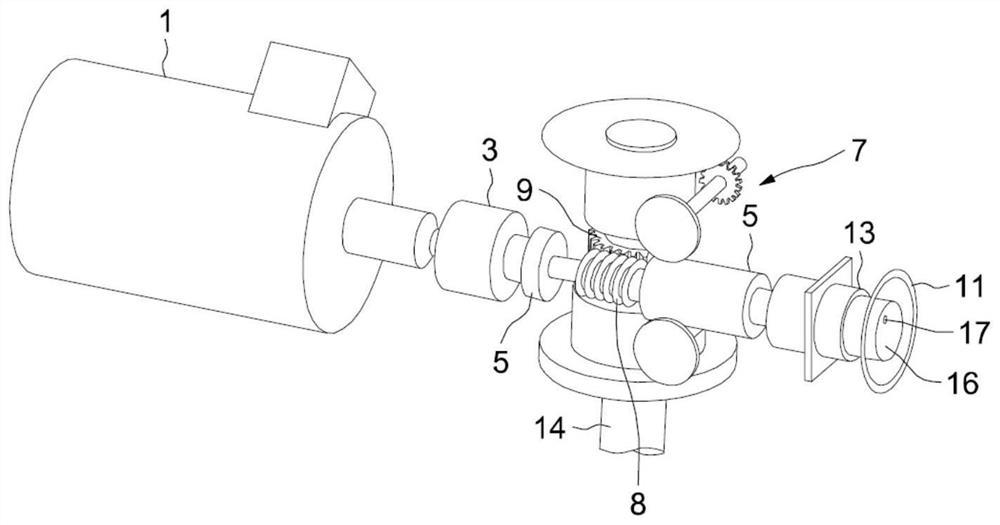

[0023] As a non-limiting example, the invention is described below as it applies to applications such as figure 1 The multi-turn servo motor system shown.

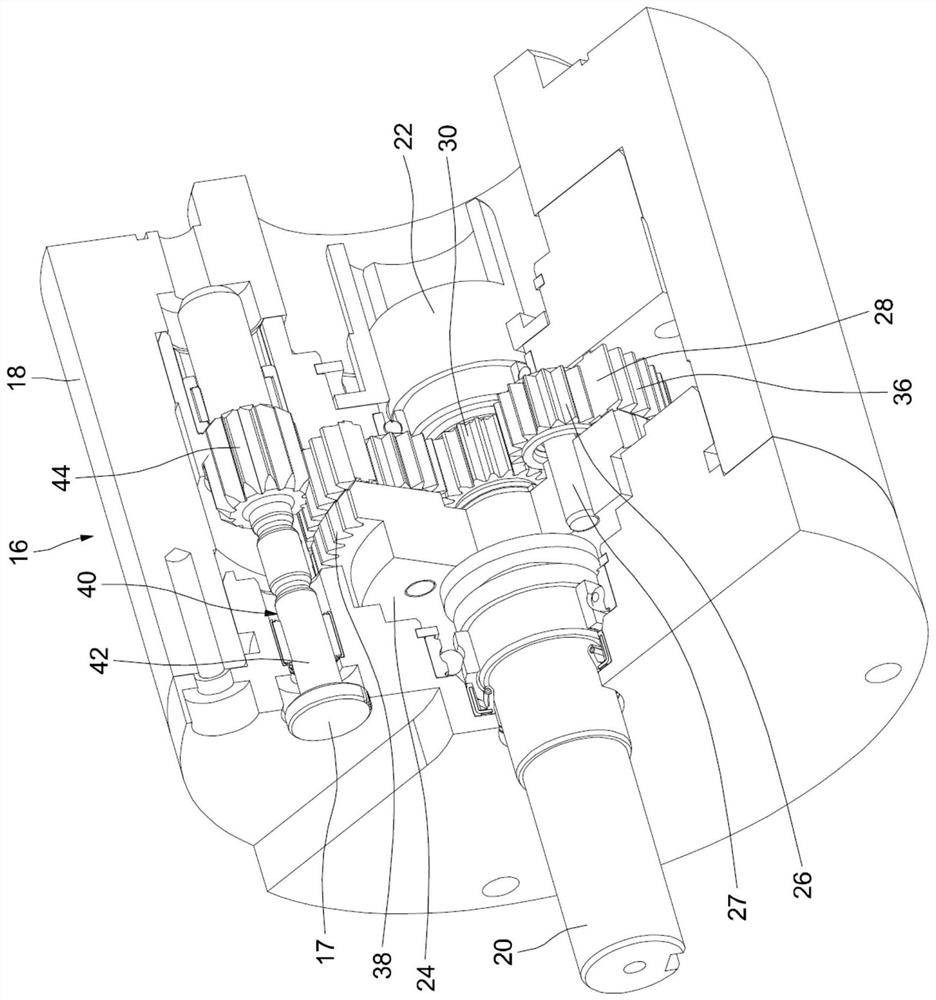

[0024] According to the synaptic block diagram of the figure, the system includes a motor 1, a planetary gear train 3, a beam force limiter 5 and a reducer 7 installed in series, which includes a worm 8 and a gear 9 driven by a screw 8 and connected to An output shaft 14 is fixed for rotation together, for driving an actuator member (such as a rotating member for closing and opening a valve of a pipe). The figure further shows a flywheel 11 for a manually actuated actuator and a clutch system 13 mounted in series with the worm 8 and a planetary gear train 16 provided with a control member 17 according to the invention.

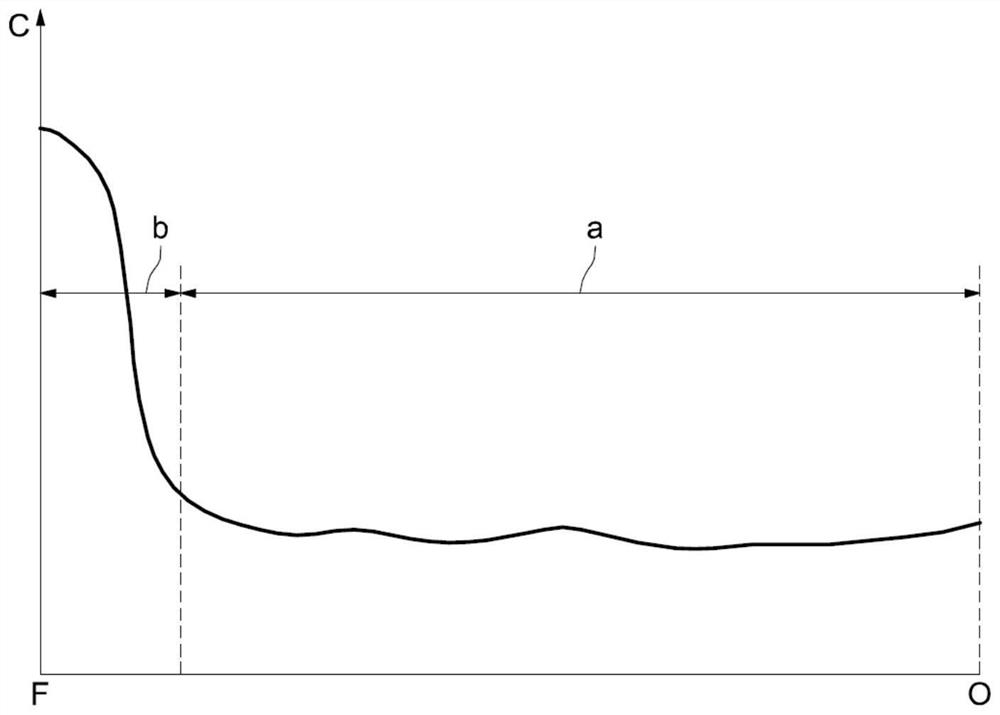

[0025] figure 2 The characteristic curve of the torque C of the moving actuator member of the valve is shown as a function of the travel of the member between an open position O on the right side of its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com