Steamed bread processing equipment

A technology for processing equipment and steamed buns, which is applied to dough forming machinery or equipment, baking, dough extruders, etc. It can solve the problems of lower production efficiency, great difference in taste, and consume a lot of time and energy, so as to simplify the processing steps , less equipment investment, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

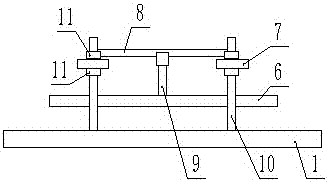

[0027] For convenience of description, the side of the panel 6 close to the cam 15 is defined as the front side, and the side of the panel 6 away from the cam 15 is defined as the rear side.

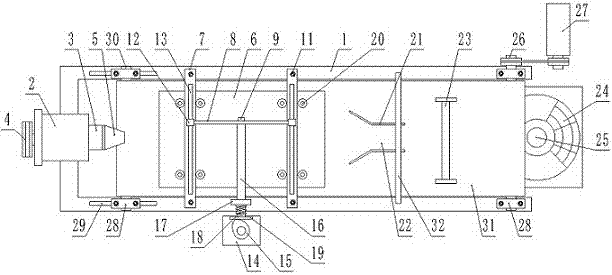

[0028] Such as figure 1 As shown, the present invention comprises a frame 1, a noodle delivery mechanism, a noodle column rounding mechanism, a noodle column guide mechanism, a cutting mechanism, a shaping mechanism and a noodle delivery mechanism arranged between the noodle delivery mechanism and the shaping mechanism, which are sequentially arranged on the frame 1 The transfer mechanism that plays the role of noodle column delivery between them, the noodle delivery mechanism is fixedly connected with the frame 1. In order to increase the safety factor in the operation process, the surface column rounding mechanism, the surface colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com